It's hard to stop a trane.Our 35 year old Trane is still humming along.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

R22 systems? Keep them running or what?

- Thread starter The motor guy

- Start date

Many, MANY HVAC contractors pay their techs commissions to sell (usually unneeded) new systems, and the biggest, mostly heavy advertising ones are the worst! R22 is still available, although expensive-the supply houses will pay for good, used clean R22, it gets reprocessed, and resold. My Lennox central air is 30 years old now, I put a new compressor in it ~8 years ago, needs a contactor occasionally, but still cooking. Haven’t had to use any of my ~50 pounds of R22 I have left in it either, the compressor was just a mechanical failure.My brother has found a couple of pretty decent side job HVAC techs on Facebook marketplace. They've been more than willing to fix my 1991 Armstrong HVAC system which has only needed a run start cap and thermostat wiring since new. The guy I like better said to rock the R-22 system as long as possible. It seems that the bigger shops have the philosophy that they'll fix it when their busy and want to put in a whole system when they're slow.

- Joined

- May 31, 2024

- Messages

- 518

One consideration is the efficiency of the replacement unit.

When will the cost of energy equate to a plus savings?

I've heard an HVAC guy swear off the newer 95% efficient furnaces. Because the repair and installation costs over an 80% are so much higher, it will be many years to recoup the expense, if ever.

When will the cost of energy equate to a plus savings?

I've heard an HVAC guy swear off the newer 95% efficient furnaces. Because the repair and installation costs over an 80% are so much higher, it will be many years to recoup the expense, if ever.

One of the most popular heat pumps up here is Bryant, made in China. New info on run time yet. My 410 A, 3.5 Ton American standard is 12 years old, with just a capacitor replacement I did myself.

The motor guy

Thread starter

- Joined

- Nov 29, 2009

- Messages

- 9,529

An old trane lolIt's hard to stop a trane.

If its not leeking then replacing elecctrical parts is a no brainer. Once it gets rotten and starts leaking then it might be rotted out and time to replace.

$1300 for a 1/4 HP AC motor, Ouch. HVAC is such a rip off. That motor in the Industrial world is $100 bucks. But when you need it, you need it so I would have done same.

$1300 for a 1/4 HP AC motor, Ouch. HVAC is such a rip off. That motor in the Industrial world is $100 bucks. But when you need it, you need it so I would have done same.

11K sounds like robbery to me. I've been buying 15oz cans of 22 on ebay.. It's still relatively affordable. I recently got 2 more cans for about 78 bux delivered.. I also bought some leak stop for like 30 bux, so it's worth a shot. Hopefully it works or I have 2 more cans left.

https://www.amazon.com/dp/B01M6X7W2T?psc=1&ref=ppx_yo2ov_dt_b_product_details

https://www.amazon.com/dp/B01M6X7W2T?psc=1&ref=ppx_yo2ov_dt_b_product_details

The motor guy

Thread starter

- Joined

- Nov 29, 2009

- Messages

- 9,529

Yeah you kind of get the shaft when it just needs to be fixed quickly to keep a happy tenant.If its not leeking then replacing elecctrical parts is a no brainer. Once it gets rotten and starts leaking then it might be rotted out and time to replace.

$1300 for a 1/4 HP AC motor, Ouch. HVAC is such a rip off. That motor in the Industrial world is $100 bucks. But when you need it, you need it so I would have done same.

The motor guy

Thread starter

- Joined

- Nov 29, 2009

- Messages

- 9,529

I get that it cost money for insurance, licenses, building rent etc, but $1000/hr is ridiculous. I might as well start an hvac business and just pay couple guys to go out everyday and fix acs if that's the kind of money they make..Yeah you kind of get the shaft when it just needs to be fixed quickly to keep a happy tenant.

The motor guy

Thread starter

- Joined

- Nov 29, 2009

- Messages

- 9,529

I get that it cost money for insurance, licenses, building rent etc, but $1000/hr is ridiculous. I might as well start an hvac business and just pay couple guys to go out everyday and fix acs if that's the kind of money they make..

The motor guy

Thread starter

- Joined

- Nov 29, 2009

- Messages

- 9,529

Pretty sure you can get that pink 10 lb cylinder for relatively cheap11K sounds like robbery to me. I've been buying 15oz cans of 22 on ebay.. It's still relatively affordable. I recently got 2 more cans for about 78 bux delivered.. I also bought some leak stop for like 30 bux, so it's worth a shot. Hopefully it works or I have 2 more cans left.

https://www.amazon.com/dp/B01M6X7W2T?psc=1&ref=ppx_yo2ov_dt_b_product_details

The motor guy

Thread starter

- Joined

- Nov 29, 2009

- Messages

- 9,529

Double post, please delete

Unless the compressor died or the refrigerant leaks, I'd replace those other electronics and fan / motor. Those parts are easy to replace without a license and get those parts online. Replacing a whole system that cost 10k for a $400 part is insane, especially when the newer units are more fragile than the older simpler boring stuff.

All you can get right now is equipment with R410A at least around here.There is no reason to buy a 410 system.

Buy a system with the new refrigerant.

Not sure what the layout is like but the Bryant’s are fairly small and suitable for importing in shipping containers.That is a shame.

Trane used to be top of the line equipment.

Last edited:

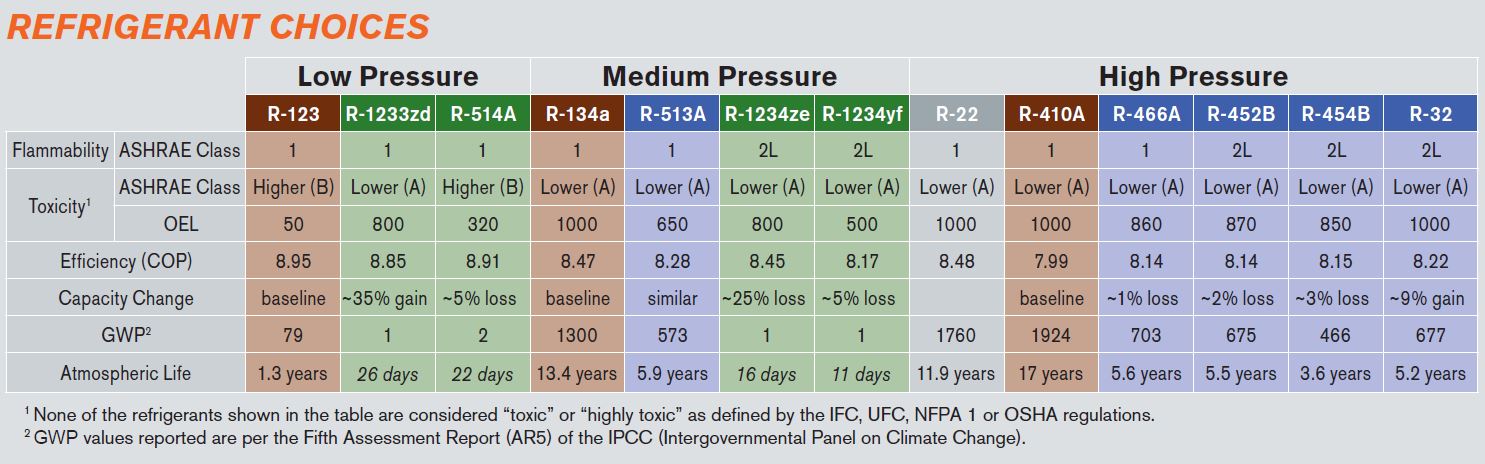

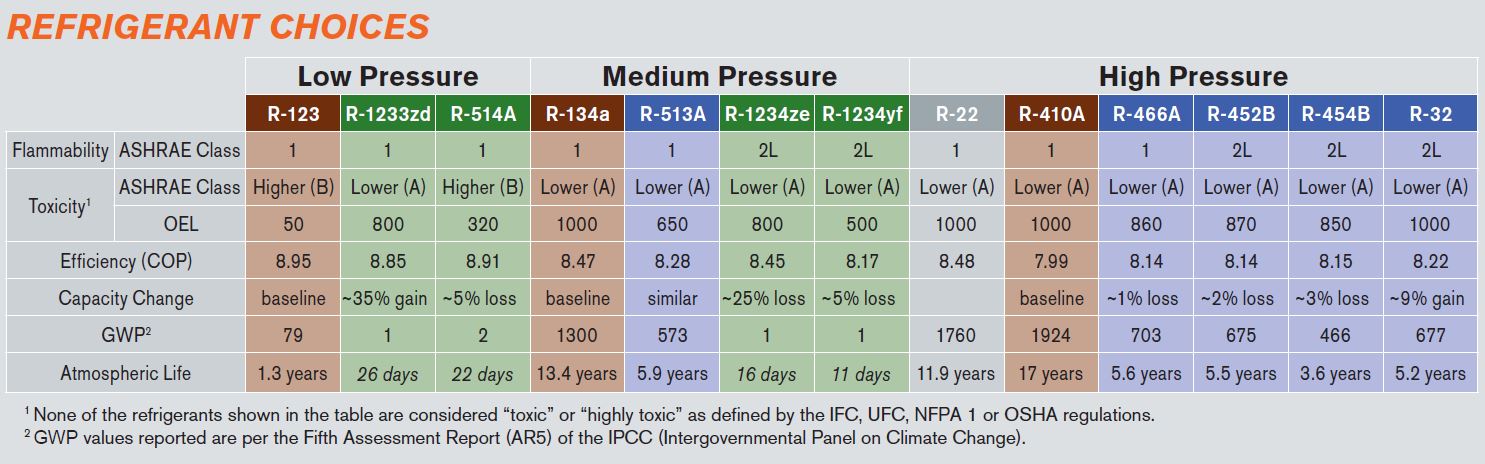

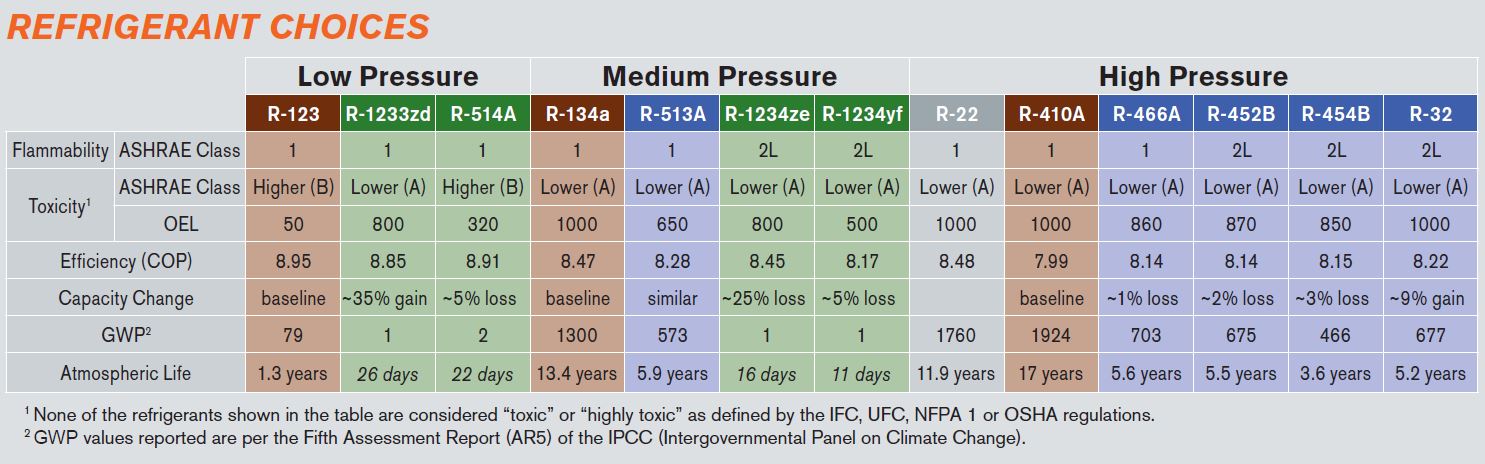

Possibly of interest to some of us here. Note that the efficiency differences between refrigerants is not as great as many would have you believe. System size related to refrigerant is another matter, for sure. As some refrigerants require larger systems.

Last edited:

A big part of operational efficiency is variable speed compressors, fans, electronic controls. As opposed to a simple 24 VAC contactor, dual run capacitor(s) for the fan & compressor. The variable is how much faster the new stuff vacuums money out of your wallet! The GWP factor is a bit of a scam, as well-unless your system is a leaky piece of junk perpetually venting to the atmosphere, and the refrigerant isn't reclaimed & disposed of properly at EOL or major service, it's not going to effect anything. Other than the suppliers ability to rip people off with new refrigerants! Anyone remember when the HFCs like 134A, 410A & 404A were the greatest thing ever?? Now they're suddenly "no good"...Possibly of interest to some of us here. Note that the efficiency differences between refrigerants is not as great as many would have you believe. System size is another matter, for sure.

The motor guy

Thread starter

- Joined

- Nov 29, 2009

- Messages

- 9,529

At the time I didnt really think about it, but I got stiffed good on that fan motor replacement. $1300?Unless the compressor died or the refrigerant leaks, I'd replace those other electronics and fan / motor. Those parts are easy to replace without a license and get those parts online. Replacing a whole system that cost 10k for a $400 part is insane, especially when the newer units are more fragile than the older simpler boring stuff.

AZjeff

$50 Site Donor 2023

Attic or basement what’s the difference? Go boom either place.So wait, We can put a natural gas furnace in the attic and they freak out about slightly flammable freon?

Similar threads

- Replies

- 72

- Views

- 6K

- Replies

- 33

- Views

- 2K

- Replies

- 61

- Views

- 6K