Just a sample… we are talking about higher oil temperatures. That guy is a master mechanic and teaches. Most guys do go 5w-30 on the track.LoL ... did you read the rest of the thread. Pretty much everyone else posting in that thread wouldn't use 0W-20 on the track. You sure like to latch-on to the 3 sigma stuff and try to use it as gospel.

Reminds me of some guy on YouTube that used 5W-20 on the track and boasted how his UOA was so good. Then his engine started making noises and he tore into the engine and looked at the bearings that were pretty much trashed. I even made a comment in one if his YT videos that he was asking for problems if he used too thin oil for track days. So the UOA gave him zero information on what was actually going on. The wear debris was probably way too big to be measured by the UOA.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Ravenol Ultra Fuel Economy 0W-8

- Thread starter Shel_B

- Start date

- Status

- Not open for further replies.

Doesn't mean he knows a lot about engineering and Tribology.That guy is a master mechanic and teaches.

For a good reason ... more engine protection as the oil thins out more from the added heat.Most guys do go 5w-30 on the track.

Well… you wanted the info. (right)Doesn't mean he knows a lot about engineering and Tribology.

For a good reason ... more engine protection as the oil thins out more from the added heat.

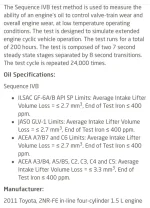

They sure need to get better at their wording. It makes it appear that (1) test takes 200 hours, and is done 24,000 times to achieve certification. That’s… 4.8 million hours, or 548 years per test.The sequence IVB JASO GLV-1 has the same requirements as API SP and ILSAC GF-6

Attachments

There is abundant scientific evidence that an oil with a lower HT/HS causes more wear than one with a higher HT/HS. Whether that difference is significant to you and/or outweighs the fuel savings is up to you, but it is factually incorrect to state that there is no evidence. Denying basic physics to support your personal cause doesn’t make the cause valid.nor the opposite

Yes there are standardized tests for fuel economy differences between oils that give statistically significant results. One would assume - and hope - that this is where the number originated.Supposedly, the 1.15% increase in mileage is with all other factors held constant except the oil viscosity. At least that's how it should be presented if that's the case. No question that fuel mileage is dependent on many factors.

A report on the additive package from 0w8

https://www.sae.org/publications/technical-papers/content/2020-01-1426/

https://www.sae.org/publications/technical-papers/content/2020-01-1426/

Attachments

Last edited:

It is on the edge of damage. That’s the whole point, the HT/HS is the bare minimum that is needed and often supported by other mechanisms to ensure oil never thins too much. Very little to no MOFT headroom.Oh… I got that side. HTHS and MOFT good. But you stated CAFE drives car manufacturers to bare minimum viscosity and puts your car on the edge of damage. What is that plenty of engineering and science to whatever your are talking about? Crankshaft imperfections at thin MOFT would show some bearing damage at least that could be seen with UOA, right?

The only real testing done for each individual type engine that tears down the engine and analyzes results are done by the car manufacturers. Oil is too thick when it is cold, too thin when hot. (well… you know that) Really… the only real proof is the 5w-20 oil cars are still on the road. If there was not proper MOFT headroom that edge of damage you described would take out less than perfect balanced crankshafts.

Last edited:

b71 2312 - 0w30 common factory fill of psa/stellantis. as you guess enough modtc too.

look at 2019 update, how everything is increased.....

i´ve see enough uoa (over several years) , it seems at 9000km addpak is almost dead...factory oci is 25000km...

enough stories of oil drink habit or noises/wear. since i´m thickie, i avoid this bloody nonsense.

anything below 3,5 hths is red zone for me.

Talking about HTHS and MOFT, the specific application has to be considered. Testing has shown that wear increases below 2.5 cP though IIRC it also showed a slight increase again above ~3.5 cP. I can't remember the test engine (or replicated simulation) used for that testing. Does anyone have the link to that testing?

The MOFT is a dynamic parameter, not a static one. As RPM and load changes, so does the MOFT. It also varies with different surface roughness, journal diameter, and clearance.

The MOFT is a dynamic parameter, not a static one. As RPM and load changes, so does the MOFT. It also varies with different surface roughness, journal diameter, and clearance.

I’d be willing to bet that isotropic finishing supports thinner MOFT, relatively speaking. It would, in my mind, require a little more flow since oil won’t cling to the super-polished surface though. This would be where dry film coatings would be helpful I would expect; super smooth surface for low friction, with either an oil-retaining coating or a dry lubricant.Talking about HTHS and MOFT, the specific application has to be considered. Testing has shown that wear increases below 2.5 cP though IIRC it also showed a slight increase again above ~3.5 cP. I can't remember the test engine (or replicated simulation) used for that testing. Does anyone have the link to that testing?

The MOFT is a dynamic parameter, not a static one. As RPM and load changes, so does the MOFT. It also varies with different surface roughness, journal diameter, and clearance.

To me, that would be what would drive huge growth in the coating industry- take an average production engine and do performance and mileage testing, then disassemble it, isotropically finish the rotating assembly and metal-on-metal parts; coat the bearings, combustion chambers and valves, pistons, rocker arms, intake manifold & heads and then re-run all tests. I know it’s not really fiscally responsible but I’m willing to bet a steak dinner that it would be worth 5-10% efficiency & some HP. Good times!

Isotropic. There's a word one doesn't hear in everyday speech. I'm used to hearing that descriptive adjective surrounding meaningful, free-space radio antenna radiation patterns.

I suppose it could be applied to MOFT and spacing properties between engine parts... the development of tech and efforts to maximize and make more rigorous the upkeep of those spaces.

I guarantee 0W-8 has considerably less "space" between parts than a 30 weight or 40 weight oil. Are they protecting as they should, or are parts bumping in the night?

I suppose it could be applied to MOFT and spacing properties between engine parts... the development of tech and efforts to maximize and make more rigorous the upkeep of those spaces.

I guarantee 0W-8 has considerably less "space" between parts than a 30 weight or 40 weight oil. Are they protecting as they should, or are parts bumping in the night?

Last edited:

- Joined

- Sep 26, 2010

- Messages

- 9,837

OT - but I had the front and rear gears on my Jeep REM Isotropic polished to eliminate the need for heat cycles to break them in. You still need to change the oil at 500 miles, but the wear metal generation is substantially reduced, they run cooler, and you can just "drive them".

NASCAR uses the same process for their gears because they do not have time to break them in.

NASCAR uses the same process for their gears because they do not have time to break them in.

So, what are we talking here ... precision machining and an upscale, micron-level polishing that inherently reduces friction?OT - but I had the front and rear gears on my Jeep REM Isotropic polished to eliminate the need for heat cycles to break them in. You still need to change the oil at 500 miles, but the wear metal generation is substantially reduced, they run cooler, and you can just "drive them".

NASCAR uses the same process for their gears because they do not have time to break them in.

Does such effort allow for minuscule 0W-8 MOFT and similar fuel savings?

Does it really work for modestly extended periods of time, such as in an uncaring consumer's engine?

It seems expensive. AEHass should weigh in.

Last edited:

Yes it’s expensive but there are other benefits than just reduced friction & wear- parts run cooler, oil has an easier life since there isn’t such a height difference between asperities on the surface, so parts stay in hydrodynamic lubrication more. It’s something that would have to be applied on a MASSIVE scale for a production industry to make financial sense.So, what are we talking here ... precision mfgring and an upscale, micron-level polishing that inherently reduces friction?

Does such effort allow for minuscule 0W-8 MOFT and similar fuel savings?

If so, it seems expensive.

In the cottage industry of engine coatings & high-performance hand-built engines, and trying to save $$$$ parts from an oil-related failure, the $500-1000 you’d spend to fully coat all relevant parts would pay for itself IMO.

If we’re getting this crazy with specialized treatments, let’s throw cryogenic processing in the mix before the isotropic finish & coatings. Now we’re cooking with gas!

Then you know nothing about why the manual says what it does. It is an inherently non-technical or non-mechanical reason as shown by the CAFE award letters I and others have posted here. Engines may have design features that allow the engine to tolerate thinner oils but other than that there are no advantages. There is nothing superior about a lower HT/HS oil besides fuel economy therefore there is no reason why a manufacturer recommends that grade other than lowered fuel consumption. Some people on here think it is because the oils are “better” mechanically but that is not correct.I am all for your input but I consider Operators’s manual above your pay grade. If it was just me I would walk away but if you throw in pure CAFE and no engineering or science involved, well I gotta say something. In 2021 Mazda came out most reliable car brand, without your input.

The engineering and science comes in where the automaker spends large amounts of money designing engines to tolerate thinner and thinner oils and we all pay for that - as well as the science that’s required by the blender to formulate these oils.

I wonder if anyone has ever done a cost-benefit analysis on that as it relates to the consumer.

Variable valve timing… See below.Then you know nothing about why the manual says what it does. It is an inherently non-technical or non-mechanical reason as shown by the CAFE award letters I and others have posted here. Engines may have design features that allow the engine to tolerate thinner oils but other than that there are no advantages. There is nothing superior about a lower HT/HS oil besides fuel economy therefore there is no reason why a manufacturer recommends that grade other than lowered fuel consumption. Some people on here think it is because the oils are “better” mechanically but that is not correct.

The engineering and science comes in where the automaker spends large amounts of money designing engines to tolerate thinner and thinner oils and we all pay for that - as well as the science that’s required by the blender to formulate these oils.

I wonder if anyone has ever done a cost-benefit analysis on that as it relates to the consumer.

https://blog.amsoil.com/what-happens-if-i-use-the-wrong-weight-viscosity-of-oil/

- Status

- Not open for further replies.

Similar threads

- Replies

- 17

- Views

- 2K

- Replies

- 63

- Views

- 4K

- Replies

- 34

- Views

- 9K

- Replies

- 6

- Views

- 799