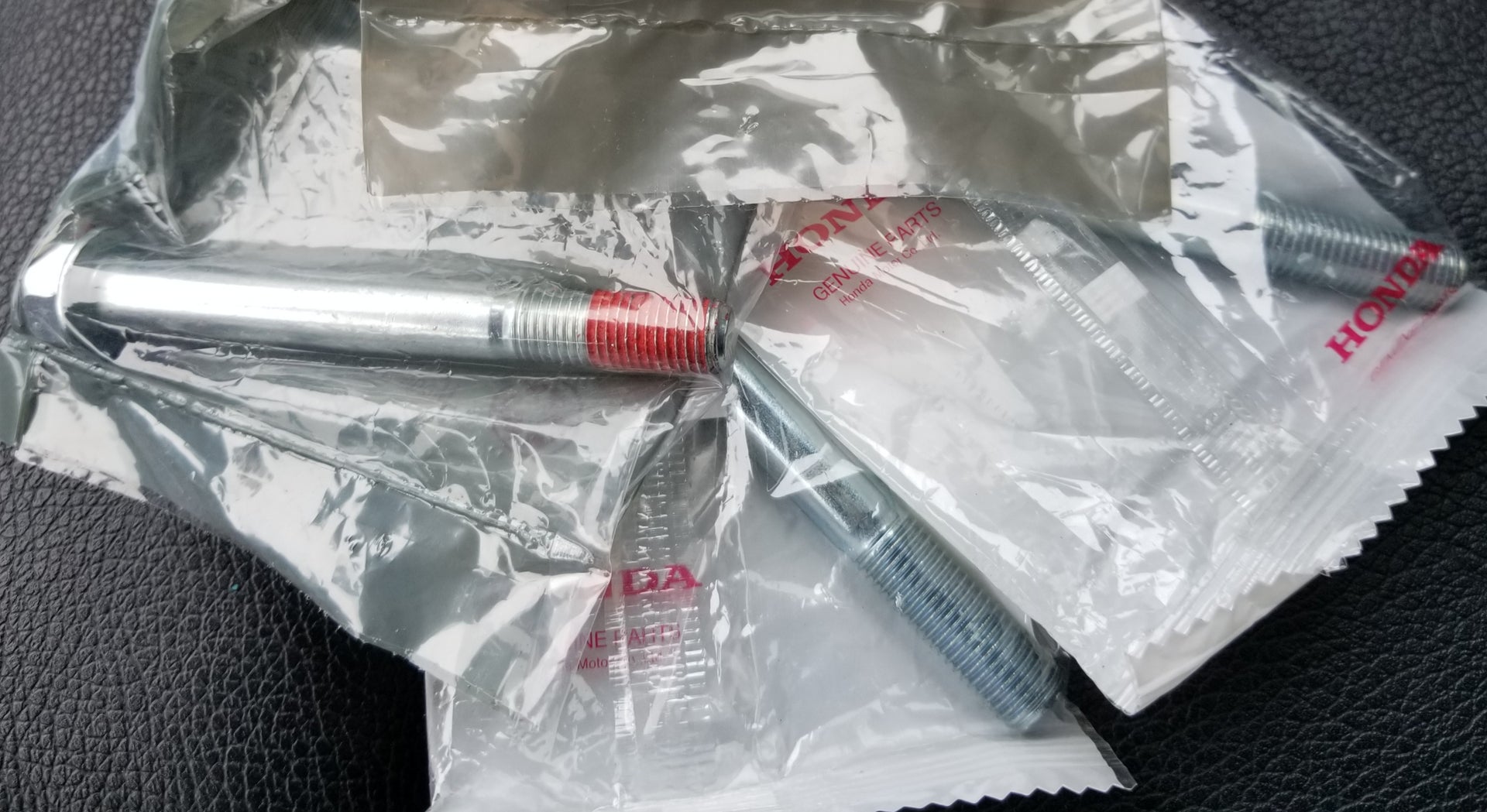

I had wondered if that bolt had to be replaced since I saw it mentioned in some Honda service manual excerpts, but the kits don't come with it and there's no mention of replacing it in the kit instructions. Asking on the piloteers forum, the prevailing response was that most Honda technicians don't replace them and just put new threadlocker on. I suppose for the whopping $6 to order a new one from Majestic it's not a big deal to replace it. Doesn't seem like it's a TTY bolt like a cylinder head bolt, but I will agree it's a bad day if it comes loose or shears.

2011 Timing Belt - Idler Pulley Bolt Broke

It is rare, but it does happen.