Originally Posted By: Gary Allan

Quote:

Many times it seem like you make this argument where the filter has virtually no PSID unless the oil pump is in relief mode

And I stand by this assertion. I've observed it with my own eyes. If our friend with the Honda ever gets below relief with his 50 weight oil, and isn't @ 9000rpm ..he'll see it too.

I think what you saw was a non-stable condition and you have mis-interpreted it. I’ve lost track of some of the details of your test (I have to admit), so maybe you should start a brand new tread with the details and maybe we can get to the bottom of this debate.

Originally Posted By: Gary Allan

Quote:

but that is not true.

It is more than it is not.

Try pouring any oil through a filter ...ANY filter. Compared to a funnel it's HIGHLY restrictive. That restrictive property is next to nothing when a much more highly restrictive element trumps it.

Whoa ... you just admitted above that a filter element is (quote) “HIGHLY restrictive”. Yes, it has a fixed restriction factor ... obviously. Let’s not compare the restrictiveness of the filter to the engine for example. But, if you recall some of our past conversations, some engines might flow better (ie, be less restrictive) than others. And some filters are obviously more restrictive than others. What happens when you put a very restrictive filter on a very free flowing (Subaru) engine? You can see that the restriction ratio of the filter/engine can vary.

Originally Posted By: Gary Allan

Out of relief, the engine is way bigger.

This is where you are messed up. It doesn’t matter if you’re out of relief or not ... the filter still has a PSID and the engine still has a PSID. The resistance factor of the filter and engine do not change ... they are FIXED / CONSTANT.

When the pump is “out of relief” (ie, NOT in relief), then ALL the oil volume must go through the filter and engine. That flow causes some PSID across the filter, and that flow causes some PSID across the engine. If the pump output needs to be 80 psi to push the entire pump’s volume through the filter/engine circuit (NONE going to sump via relief valve), then there might be 6 PSID across the filter, which means the engine oil pressure sensor after the filter will see 80 – 8 = 72 psi. Dude, there IS some level of pressure drop across the filter of some level anytime there is flow through it. Increase viscosity, keep volume constant = more PSID. Increase volume, keep viscosity constant = more PSID. Increase both viscosity and volume = even more PSID than the first two senarios.

Originally Posted By: Gary Allan

When the relief is open, the flow sees two paths ..the highly resistive filter and the highly resistive relief. The relative resistance of the filter is based on the amount of shunted flow versus realized flow ..up to the limits of the bypass valve.

The filter doesn’t care how much flow is shunted to the sump. All it cares about is how much pressure is on its inlet. When the pump is in relief mode the pump’s output pressure is at the max regulated pressure ... anyone can see that. This means the flow volume going through the filter is at the max for the viscosity or oil used, and that means the filter’s PSID is at the max for these conditions. As I’ve always said in the past, the filter’s PSID and the engine’s oil pressure reading will always be max when the pump is in relief mode.

Originally Posted By: Gary Allan

Now, YES, when you approach higher levels of flow (that very few people will ever see) the filter itself, being a bunch of orifices, will produce PSID on its own.

The filter ALWAYS produces some level of PSID on its own ... always. As said above, for any system the maximum flow volume and pressure to the filter/engine will occur during pump relief mode. You get max flow volume at max pump output pressure ... always! So, you get max filter PSID and max engine oil pressure ... if you can never see or realize this then you will never understand what’s really going on.

Originally Posted By: Gary Allan

TRUST ME. If there was any truth to linear models of PSID ..then every filter out there would be in perpetual bypass at highway speeds. That PSID is COMPRESSED due to the series nature of the single, non-divergent, flow.

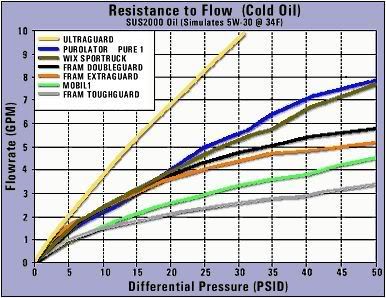

It’s not really linear (but pretty close) ... the PSID falls off some with increased flow volume. See the AC Delco “PSID vs. Flow” graph. Why do you think there is a PSID shown on that graph with very little flow volume?

Originally Posted By: Gary Allan

Our OP is always in relief (his hot idle is above his alleged relief setting WAY downstream) ..hence he will always be at SOME elevated PSID.

Agreed ... that’s because his HV oil pump is basically performing at idle like a normal pump would perform at high RPM.

Originally Posted By: Gary Allan

If he threw in whatever oil was necessary to get below the relief at idle ..the M1 and the K&N would not alter the pressure at the sender/sensor.

True ... at least we see that the same.

Originally Posted By: Gary Allan

Relief results in (higher) PSID. It's next to nothing outside of relief at all sensible flow rates.

Don’t agree here ... this seems to be the point we always get hung up on. Let me ask you this – what do you think a filter’s PSID is just a hair before the pump goes into relief mode? What do you think the pump output volume is just a hair before it goes into relief mode? (Ans – just a hair less than the max it could ever produce, and that means a hair less than the max filter PSID and engine oil pressure will ever be seen at this point).