I use a little grease on the studs

You broke the stud by constantly overtightening, you found out its limit. DON'T grease the studs! Just clean them with a wire brush or wire wheel.

I use a little grease on the studs

I've taken off a wheel that had all 5 lugs torque to some crazy way above 200ft-lb. I want to guess 400ft-lbs.

That car came to me with 75-100PSI in all 4 tires to start with. And then i was asked to rotate the wheels and found that crazy torque. I had a 1000ft-lb impact at the time that could take honda crank bolts out and it struggled with those lug nuts. Oddly enough no damage or stretching from what i can tell. I was almost for sure i would be selling the customer 5 studs and lugnuts.

I've also had one snap on be from normal tighten with a 12inch ratchet. So it can just be very random.

Absolutely- bought tires at Walmart about a month ago. Based upon my experience there, became suspicious of their competence. Got home and checked wheels. Took ALOT of force with a two foot long breaker bar to loosen some lugs. Not only that, but some of the lugs were rounded so that a socket would not grip well. Walmart replaced the lug nuts after alot of complaining.Most mechanics and tire shops overtorque the lug nuts

They zip it with an air gun 600 lb ft of torque or more, and usually torqued unevenly, too.

In general, I believe torque values assume a lightly oiled (not dry) fastener. IMO, lube is okay for wheel stud threads provided none is applied to the cone portion that contacts the wheel. My Porsche owners manual says to apply "anti seize paste" to threads but not to the cone. Porsche cars are built for serious racing and I think Porsche knows a thing or two about attaching wheels. Good enuff for me...Torque values for wheel studs are for clean and dry threads (not lubricated).

Porsche is unique in this regard.In general, I believe torque values assume a lightly oiled (not dry) fastener. IMO, lube is okay for wheel stud threads provided none is applied to the cone portion that contacts the wheel. My Porsche owners manual says to apply "anti seize paste" to threads but not to the cone. Porsche cars are built for serious racing and I think Porsche knows a thing or two about attaching wheels. Good enuff for me...

You are right. I researched the lube on fastener topic and found that torque values are not affected if applied to the threads only. Values are affected if lube is applied under the bolt head. Seems counter intuitive. My can of Permatex anti seize says to apply it and use the specified torque values (no reduction in torque). Their web site says the same. Perhaps Permatex knows something? I think MB and others specify dry unlubed threads to avoid ppl slathering lube all over threads and cones to play it safe and avoid liability. I forget the company name of a lug nut manufacturer/supplier that says lube on the lug nut threads is okay but not on the studs themselves. I guess this is to avoid getting any on the cones?Porsche is unique in this regard.

For many other cars, Mercedes, Volvo, Toyota, to name a few, the torque values specifically state “clean, dry, unlubricated threads”.

I researched the lube on fastener topic and found that torque values are not affected if applied to the threads only. Values are affected if lube is applied under the bolt head. Seems counter intuitive.

Perhaps Permatex knows something?

This is all too complicated for such a simple concept. I see both recommendations from reputable sources.

Thank you ABN- you always have good comments . I know all this from SOM class and agree, but the operative word is "degree". Yes, cof is reduced but how much? If you agree Permatex does know "something" and they say to apply their AZ wo reducing torque, what does this say regarding "degree" or "physics" ? Bottom line is - it doesn't matterNo reflection on your research but your source(s) is simply wrong. Makes no difference who says otherwise.

If the COF changes ( for any reason) then torque ( turning force) WILL be affected to a degree. That's simply physics and an engineering constant- that's an inarguable fact.

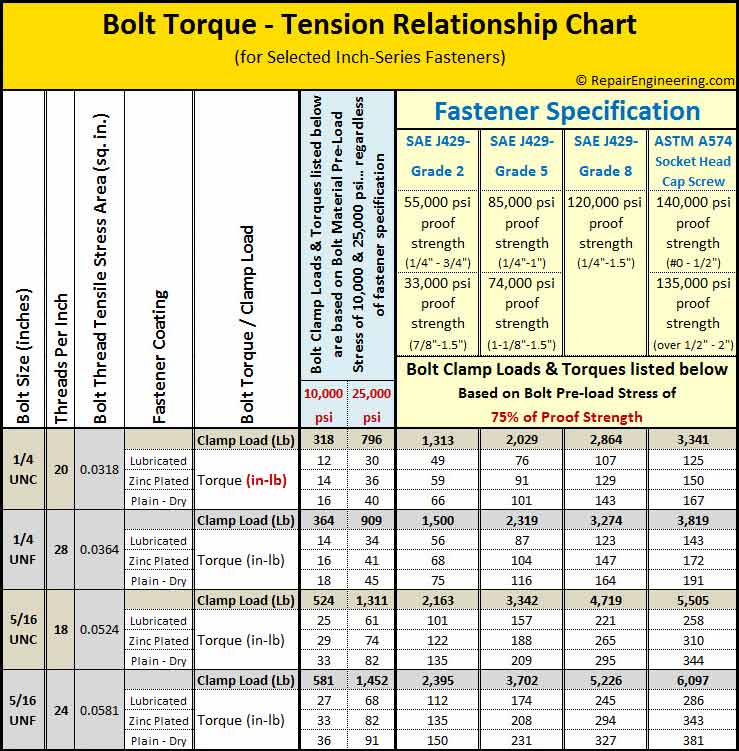

In fact, they do and here it is. "Torque" is a twisting force- a fastener requires TENSION to properly secure a joint. ( they are NOT the same)

PT knows that you don't reduce the TENSION by "fooling" a wrench because now it turns "easier" because of a drop of oil because that will affect the mechanical integrity of the joint.

It is relatively simple in concept but a bit more complex for "critical fasteners" but made confusing because of the (probably well meaning) misinformation out there.

Thank you ABN- you always have good comments . I know all this from SOM class and agree, but the operative word is "degree". Yes, cof is reduced but how much? If you agree Permatex does know "something" and they say to apply their AZ wo reducing torque, what does this say regarding "degree" or "physics" ? Bottom line is - it doesn't matter

The discussion was about lubing wheel studs and I claimed it was ok to use lube but it went sideways. Not arguing physics although we can if you want. Even equations ...LOL

Last time I specifically visited Permatex site to check this out, it did not contain that "warning" or I missed it. Otherwise, I would not have mentioned it. Good to know. Thank YouAll 3 Permatex Anti-Seize products say "WARNING: Not for use on wheel lug nut or stud applications." in their respective TDS.

They do all say to 'use normal torque values', but that is very much at odds with what everyone else says, including a company owned by the same group (ITW) as Permatex:

A deeper understanding of Anti-Seize - ROCOL

In this article on anti-seize we talk all things gaskets, torsion-tension relationship, torque settings and get into the nitty gritty of the K factor and friction coefficient.www.rocol.com

"Because the use of an anti-seize changes the torsion-tension relationship of a fastener system, torque settings need to be recalculated."

Do Porsches uses special or proprietary wheel studs and lug nuts ? I'm confident that they don't so from a mechanical standpoint, lubing a Honda, Ford, etc won't be any different.must indicate Porsches confidence in lubing lug nuts.

Last time I specifically visited Permatex site to check this out, it did not contain that "warning" or I missed it. Otherwise, I would not have mentioned it. Good to know. Thank You

I believe that quote regarding recalculating torque settings probably rightfully applies to anti seize applied under the fastener head, not the threads themselves. I would like to know.

Permatex's list of recommended uses could easily include lug nuts. In my opinion, that warning was probably added for liability, not because of technical unsuitability. Every page in the my Porsche OM has multiple warnings about this or that and for them not to forbid use of "anti seize paste", but instead recommend it, on lug nuts must indicate Porsches confidence in lubing lug nuts.

Please follow the manufacturer recommendations for your vehicle, not what people on these forums think. These are all just everyone's opinions.

Thank you ABN- you always have good comments . I know all this from SOM class and agree, but the operative word is "degree". Yes, cof is reduced but how much?

If you agree Permatex does know "something" and they say to apply their AZ wo reducing torque, what does this say regarding "degree" or "physics" ? Bottom line is - it doesn't matter

They could just be spec'ing a low torque number, expecting to get the same clamping force. Or using a yet larger stud that is capable of taking the higher clamping force.Do Porsches uses special or proprietary wheel studs and lug nuts ? I'm confident that they don't so from a mechanical standpoint, lubing a Honda, Ford, etc won't be any different.

Was surprised (just a few days back) when DT said you have bought x number of tires for that car (130k) … the studs look good but showed me the lug nuts, not so much. They sold me a set for no more than I could get them across town.Do Porsches uses special or proprietary wheel studs and lug nuts ? I'm confident that they don't so from a mechanical standpoint, lubing a Honda, Ford, etc won't be any different.