Originally Posted By: Gokhan

The history and mechanisms of ZDDP

H. Spikes (Tribology Section, Department of Mechanical Engineering, Imperial College, London SW7 2AZ, UK)

Tribology Letters, Vol. 17, No. 3, Pages 469 - 489, October 2004

Excerpts from the ZDDP review paper:

1. Introduction

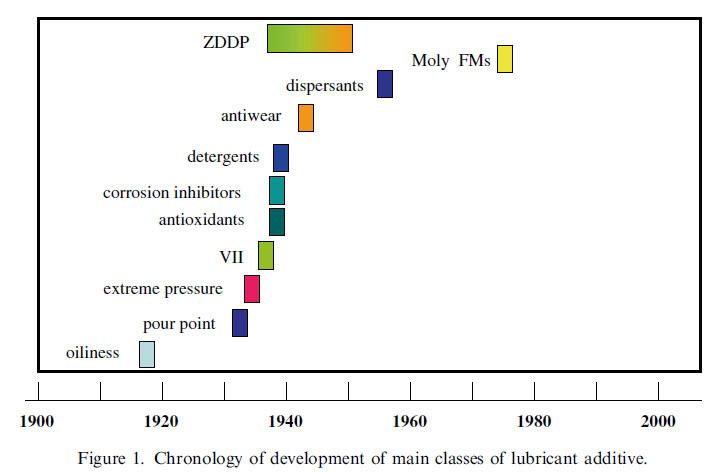

Zinc dithiophosphates (ZDDPs) are arguably the

most successful lubricant additives ever invented. They

were introduced over 60 years ago, have been in continuous

use ever since and are still being employed in

practically all current engine oils. This longevity is all

the more striking since strenuous efforts have been

made by additive companies over the last 10 years to

replace them, but in vain. It has so far proved impossible

to identify any reasonably cost-effective compound

having comparable antiwear performance to ZDDPs

in engine oils.

As well as being remarkable in their performance,

ZDDPs have also been astonishingly successful in their

ability to inspire research. The last half century has

seen an extraordinary number of published research

papers describing investigations of how these additives

behave in their triple role as antioxidants, corrosion

inhibitors and antiwear agents.

...

It is not yet clear whether the limits of phosphorus

and sulphur in engine oils will be reduced further in

future, leading perhaps to the eventual disappearance

of ZDDP. Recently, attention has started to focus on

the possibility of replacing a blanket limit on the level

of phosphorus and sulphur in engine oils to a measure

that better reflects the tendency of these elements to

volatilise and thus reach the after-treatment catalyst

[15]. This may eventually lead to a limit on P- and

S-containing additive volatility or to a test which monitors

these species in the exhaust and thus permits

imaginative new formulations based on low volatility

additives [13]. Whatever the future however, there is

no doubt that the slow pace of reduction of phosphorus

levels in engine oil specifications over the last

5 years reflects the remarkable effectiveness of ZDDP

as an antiwear additive, and the great difficulty that

additive companies have had in finding a replacement

with comparable performance.

...

4.8. Antiwear properties of ZDDP

When considering the mechanisms by which ZDDP

prevents wear, it is important to note that ZDDP is

both an antiwear and a mild EP additive, i.e. it both

reduces wear and also inhibits the onset of scuffing.

This was recognised in the 1960s, when the influence

of metal type and alkyl group structure on wear and

EP behaviour were measured and compared [35,36].

Antiwear effectiveness was found to correlate inversely

with thermal stability of the ZDDP but this trend was

less clear-cut with respect to EP effectiveness [35]. Several

studies have suggested that the antiwear behaviour

of ZDDP results from its ability to form a phosphate

film while its EP response results from its ability to

form iron sulphide [53,130]. This is consistent with

other antiwear and EP additives; sulphur-free phosphorus

additives are often effective antiwear but generally

ineffective EP additives, while organic sulphides,

although possessing some wear-reducing capability are

generally regarded as EP additives [131,132]. Similarly,

studies have shown that in mild rubbing conditions the

surface film present is mainly a thick phosphate film

but that in severe, heavily loaded/high sliding speed

conditions a much thinner film with high sulphur content

is formed [53]. Thus we need to distinguish

between the ‘‘mild-wear’’ and ‘‘severe wear’’ action of

ZDDP, the latter being essentially an EP response.

This EP aspect will not be discussed in detail in this

review except to note that studies of thermal degradation

of ZDDP have shown that most of the sulphur

present in these molecules is converted to oil-soluble

organic sulphides and disulphides and that these are

well-known EP additives.

From the literature, three main ways that ZDDP

acts as an antiwear agent have been proposed; (i) by

forming a mechanically protective film; (ii) by removing

corrosive peroxides or peroxy-radicals; (iii) by

‘‘digesting’’ hard and thus abrasive iron oxide particles.

Each of these is discussed briefly below.

The most generally accepted view of ZDDP antiwear

action is that the reaction film acts simply as a

mechanically protective barrier [133]. This prevents

direct contact and thus adhesion between metal or

metal oxide surfaces and may also operate as a cushion,

reduces the stresses experienced by the asperity

peaks of the metal substrate. The relative importance

of these two effects has not been determined. With this

type of antiwear action, once a ZDDP film forms,

practically all that wear that subsequently occurs is

presumed to be that of the ZDDP film itself. (In fact,

ZDDP tribofilms appear to be very resistant to wear

and several studies have shown that once formed they

H. Spikes/The history and mechanisms of ZDDP 483

are only very slowly worn away even when the ZDDPcontaining

oil is replaced by a base oil [89,103]). In

this case, in mild wear conditions, the only loss of substrate

may be from iron oxide which has reacted to

form a phosphate film.

The second proposed mechanism of the antiwear

action of ZDDP is that it reacts with peroxides in the

lubricant; thereby preventing these from corrosively

wearing the metal surfaces present [69,70]. This mechanism

was convincingly demonstrated by both Habeeb

and Rounds in the 1980s and no subsequent work has

challenged it.

The third suggestion is more controversial. Martin

and colleagues have proposed that iron oxide particles,

that would cause abrasive wear, embed in the

ZDDP antiwear film and are ‘‘digested’’ to form

relatively soft iron phosphate, thus negating their

harmful pro-wear effect [62,64,129]. This model

appears to have been inferred from identification of

iron phosphate in wear particles and in the rubbing

track rather than any direct evidence of iron particle

digestion. It does seem likely that iron oxide from

the metal substrate diffuses into the ZDDP reaction

film to replace some of the zinc cations with iron ones

and form iron phosphates, and recently SIMS depth

profiling has been used to show that there is a much

lower iron oxide concentration beneath the ZDDP

tribofilm that on the surrounding metal surfaces

[96]. What is lacking as yet is direct evidence that

harmful iron wear particles are removed by a digestion

process.

One interesting aspect of ZDDP wear performance

that has arisen very recently is that ZDDPs appear to

strongly promote micropitting wear. Micropitting

results from localised plastic deformation due to the

surface loadings resulting from rolling/sliding asperity

contact and it has been shown that ZDDP, because it

very rapidly forms a protective film, prevents or postpones

effective running-in of rough surfaces. This leads

to high asperity stresses being maintained and consequent

micropitting [134]. What is not yet clear is the

extent to which this is an undesirable feature of all antiwear

additives or of ZDDPs in particular.