I have purchased the rubber ones from Summit racing and they work fine....Just be sure you get one for your car...YES they do have different ones for different cars...I have a metal one that I purchased years ago from Eastwood and it works well too...but I like the rubber ones better as they do not mare the surface... I have also done the hockey puck method and that works well also....Yup, I use old hockey pucks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Floor jack pinch weld adapters. Rubber? Metal? DIY?

- Thread starter LeakySeals

- Start date

https://www.aliexpress.us/item/3256...350500374!sea!US!0&curPageLogUid=NoUVOS02Rylb

Just ordered theses jack stand adapters. On the slow boat from China. Should be in in a month. There are a variety available for just about any vehicle; feel free to take a look. Searched everywhere for a "Made in USA" option but nothing suitable. BMW dealership said they just use a large flat pad. Seems like more and more vehicles now require a "special" adapter to raise the car. Certainly, BMW and Mercedes recommend one to avoid crushing.

Just ordered theses jack stand adapters. On the slow boat from China. Should be in in a month. There are a variety available for just about any vehicle; feel free to take a look. Searched everywhere for a "Made in USA" option but nothing suitable. BMW dealership said they just use a large flat pad. Seems like more and more vehicles now require a "special" adapter to raise the car. Certainly, BMW and Mercedes recommend one to avoid crushing.

LeakySeals

Thread starter

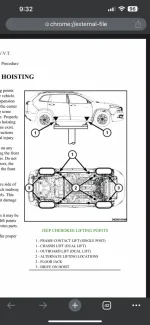

The reason for my post. Position 1 is the pinch welds. Because of the plastic rocker panel moldings, there is not enough room for a larger 3 ton floor jack or the rubber pinch weld adapters that fit that cup. So I need some thing that is narrow or rectangular, not round like a hockey puck. Position 2 is blocked by plastic undercarriage covers in the back so I’ve been using the rear aluminum control arms. Would rather not. Removing the covers is doable, but not something that can happen in five minutes. I can’t use the crossmembers or rear differential on these vehicles.

Attachments

They rest entirely on 'bottom' of pinch weld.Do they hit the body or are they resting entirely on the pinch weld? What type jack are you using them with?

I use a combo Jack & Stand

Used mostly for rotating tires and general maintenance.

https://www.amazon.com/Alltrade-640...4&sprefix=jack+and+stand+combo,aps,101&sr=8-3

Most VW have a hole in the frame that have a jack pad made to insert into them.

I used hockey pucks (two glued together) and cut a slot with a chop saw. I also bought pre-made ones and cut them down with the same saw to fit inside the plastic rocker panel molding.

Mike B

Mike B

I have something like that, but frankly, they’re not very convenient if you’re stuck on the side of the road.

LeakySeals

Thread starter

That’s neat. Do you keep them on permanently?I have something like that, but frankly, they’re not very convenient if you’re stuck on the side of the road.

View attachment 145797View attachment 145798

LeakySeals

Thread starter

Most VW have a hole in the frame that have a jack pad made to insert into them.

I do have holes like that. Going to get my calipers and see how large they are. They are position 2. Almost like the body was on a rotisserie at some point.

First look at how the factory jack lifts around/by the pinch welds. Duplicate that.

On my Subaru Forester and Crosstrek the factory jack lifted the frame on the inner and outer side of the pinch weld. The factory jack was designed so no weight was on the pinch weld itself but on either side of it. The pinch weld just held the jack in the proper place so it did not move/slide in or out.

Obviously other cars could be different.

On my Subaru Forester and Crosstrek the factory jack lifted the frame on the inner and outer side of the pinch weld. The factory jack was designed so no weight was on the pinch weld itself but on either side of it. The pinch weld just held the jack in the proper place so it did not move/slide in or out.

Obviously other cars could be different.

I do that also, but beware that some of those boxed frames are incredibly weak and I have seen them dented, especially if you don't use some wood etc., like you mention to distribute the load.YMMV but on my cars, I jack from the unibody "frame" rail. All the unibody cars I've seen, have this channel that runs the length, that looks a lot like a ladder frame. I put a 1xwhatever under jack and the lifting force is spread out. I can then toss a jack stand under the pinch rail (or under the "frame" rail) as I feel necessary.

Yes, they attach with those allen-head set screws. These are great when you have a floor jack, but if you’re on the side of the road fixing a flat, you don’t have any slot to capture of the scissor jack.That’s neat. Do you keep them on permanently?

I "think" they are the factory holes for holding the body during assembly. It must be the German way. I toured the SC BMW SUV factory last year and they had 4 prongs that the body sat on for all the assembly, at least up to the point the suspensions and powertrain were installed, then they had a different vertical prong that held the car up to the end of the line and wheels were installed, a few stations short of roll out. The first "prongs" allowed the car to attach to a rotisserie for various interior, fuel lines, wiring harness etc once all the light weight things were attached the body went to suspension.I do have holes like that. Going to get my calipers and see how large they are. They are position 2. Almost like the body was on a rotisserie at some point.

I can not find these points on my '17 Highlander and researching pinch weld adapters that avoid damaging the chip and corrosion protection. Rust belt . .yuck.

On my Subaru when you look at the factory jack, it lifts by lifting on both sides of the pinch weld. The pinch weld just holds the jack in place. There is no lifting force on the actual pinch weld.

I never lift by the pinch welds. I do use them for support sometimes if I cannot use the subframe.

But I always use a hockey puck. The current one is about 10 years old and is just now starting to split.

But I always use a hockey puck. The current one is about 10 years old and is just now starting to split.

I did this on an '05 Escape a few years ago. Some of the boxed unibody behind the front wheel looked sturdy enough, but it just started to collapse when I tried to lift from there.I do that also, but beware that some of those boxed frames are incredibly weak and I have seen them dented, especially if you don't use some wood etc., like you mention to distribute the load.

Fortunately the damage was minor, the vehicle was a total beater and the underside already looked like it had been high centered (repeatedly) before, so I didn't feel too bad

- Joined

- Jul 10, 2022

- Messages

- 5,951

Me too, basic, and work great.Yup, I use old hockey pucks.

For so many years I overthought it on the bmw buying billet adapters etc.

Then I bought the nice Esco jack stands that have flat pads and I reached out to the forum, how do I lower the car onto the stands and adapters. Someone said you don’t need adapters. You have the nice Escos

That came with flat rubber, just lower the car’s jack pads onto them…

I have one semi-hard polymer the other a tough hard nylon. Both seem to work better than a hunk a wood!!

I have something like that, but frankly, they’re not very convenient if you’re stuck on the side of the road.

If you're on the side of the road you're probably going to use the factory jack, which is designed for pinch welds.

The factory jack for my Subaru has a slot for the pinch weld but the lifting force is on either side of the pinch weld but not the actual pinch weld.

Similar threads

- Replies

- 9

- Views

- 5K

- Replies

- 4

- Views

- 8K

- Replies

- 44

- Views

- 9K