Thanks a lot. Great info.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A Comparison of 20 and 30 Weight Oils - Part 2

- Thread starter OldCowboy

- Start date

- Status

- Not open for further replies.

Originally Posted By: D189379

Thanks a lot. Great info.

+1

Thanks a lot. Great info.

+1

Lots of work compiling and presenting that info!

How they were used, what the different engines are and their condition, negates the value to me.

How they were used, what the different engines are and their condition, negates the value to me.

I decided to expand my analysis of wear levels demonstrated by 30 weight vs 20 weight oils in an attempt to gain greater analytical rigor.

My question would be what are we analyzing here? Are you implying we are to infer engine wear from an UOA?

It seems inappropriate to lump 4, 6, and 8 cylinder engines in the same analysis. So I will be reporting on each of these engine classes separately.

It would be inappropriate to lump any dis-similar engine together regardless of number of cylinders.

Additionally:

- There is only one reported sample for an OP/engine/oil combination

- Samples that had mixed weights or had additives were not considered

- Samples from engines with less than 20,000 total miles were not considered

- Samples that did not have iron as the highest wear metal were not considered Why?

- Samples that had significant fuel or water contamination were not considered

- An attempt was made to select a balanced mix of manufacturers and engines

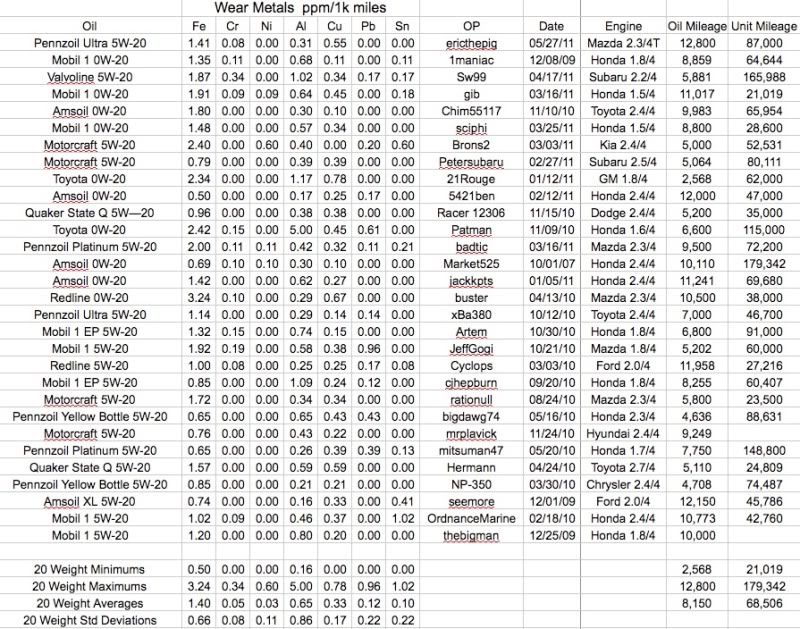

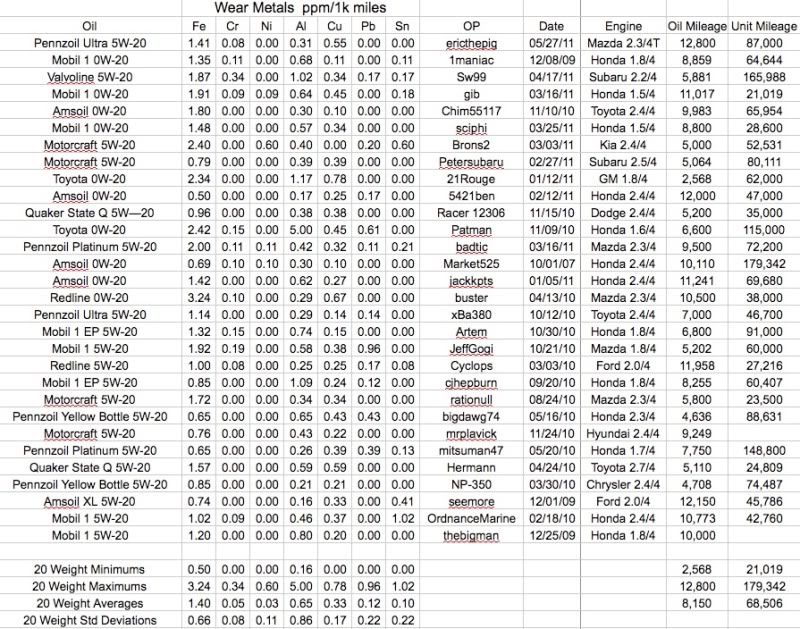

Here are the results for 4 cylinder engines. 30 weight oils are presented first.

Here is the 20 weight oil data.

With this more extensive, robust analysis, it can be seen that the 20 weight oils show marginally better results for Fe, Cr, Cu, Pb, and Sn. The 30 weight oils show marginally better results for Ni and Al. How was this data normalized? That being said, neither group of oil samples is statistically different than the other. Which statistical analysis did you use? The students T method? This casts doubt on the "known" superiority of 30 weight oils, at least with these 4 cylinder engines.

My question would be what are we analyzing here? Are you implying we are to infer engine wear from an UOA?

It seems inappropriate to lump 4, 6, and 8 cylinder engines in the same analysis. So I will be reporting on each of these engine classes separately.

It would be inappropriate to lump any dis-similar engine together regardless of number of cylinders.

Additionally:

- There is only one reported sample for an OP/engine/oil combination

- Samples that had mixed weights or had additives were not considered

- Samples from engines with less than 20,000 total miles were not considered

- Samples that did not have iron as the highest wear metal were not considered Why?

- Samples that had significant fuel or water contamination were not considered

- An attempt was made to select a balanced mix of manufacturers and engines

Here are the results for 4 cylinder engines. 30 weight oils are presented first.

Here is the 20 weight oil data.

With this more extensive, robust analysis, it can be seen that the 20 weight oils show marginally better results for Fe, Cr, Cu, Pb, and Sn. The 30 weight oils show marginally better results for Ni and Al. How was this data normalized? That being said, neither group of oil samples is statistically different than the other. Which statistical analysis did you use? The students T method? This casts doubt on the "known" superiority of 30 weight oils, at least with these 4 cylinder engines.

The results presented aren't cold hard FACTS. Its just showing a trend based on UOAs which should be taken with a dash of salt.

Basically, if 20 grade oils weren't protecting engines as good as 30 weight, we would see greater wear. Since the numbers are so similar to each other, it's kinda clear (from this collection of data) that both viscosity's are doing their job.

Basically, if 20 grade oils weren't protecting engines as good as 30 weight, we would see greater wear. Since the numbers are so similar to each other, it's kinda clear (from this collection of data) that both viscosity's are doing their job.

Originally Posted By: Doug Hillary

20W-50 was developed for the BMC Mini with integrated gearbox/engine (one common lubricant)around 1958 by Duckhams (followed by Castrol soon after). It became a good? "catch all" too and promoted the use of higher viscosities - this was not intended!!!

Cool; didn't know that. That's very interesting information. Thanks.

20W-50 was developed for the BMC Mini with integrated gearbox/engine (one common lubricant)around 1958 by Duckhams (followed by Castrol soon after). It became a good? "catch all" too and promoted the use of higher viscosities - this was not intended!!!

Cool; didn't know that. That's very interesting information. Thanks.

Originally Posted By: Ben99GT

Originally Posted By: Doug Hillary

Hi,

Artem - M1 5W-20 was introduced in 1974 - 37 years ago

I wonder what the HTHS viscosity of the original M1 5W-20 was? I'm guessing 3.0 cP or higher?

All I know is it was very thin, especially considering the heavier oils we were used to in the 60s anf 70s.

Originally Posted By: Doug Hillary

Hi,

Artem - M1 5W-20 was introduced in 1974 - 37 years ago

I wonder what the HTHS viscosity of the original M1 5W-20 was? I'm guessing 3.0 cP or higher?

All I know is it was very thin, especially considering the heavier oils we were used to in the 60s anf 70s.

Last edited:

Hi,

Ben99GT - I suspect that the HTHS viscosity was around 2.5cP

Ben99GT - I suspect that the HTHS viscosity was around 2.5cP

I loved those old cans of M1.

Remember the frying pan test?

Remember the frying pan test?

Hi,

Jeff - When Mobil first introduced their Mobiloil Special 10W-30 mineral oil into this area in the mid 1950s the cans were Gold - they looked great. The oil was very expensive too!

Jeff - When Mobil first introduced their Mobiloil Special 10W-30 mineral oil into this area in the mid 1950s the cans were Gold - they looked great. The oil was very expensive too!

OldCowboy

Thread starter

Originally Posted By: Jeff_in_VABch

I decided to expand my analysis of wear levels demonstrated by 30 weight vs 20 weight oils in an attempt to gain greater analytical rigor.

My question would be what are we analyzing here? Are you implying we are to infer engine wear from an UOA?

It seems inappropriate to lump 4, 6, and 8 cylinder engines in the same analysis. So I will be reporting on each of these engine classes separately.

It would be inappropriate to lump any dis-similar engine together regardless of number of cylinders.

Additionally:

- There is only one reported sample for an OP/engine/oil combination

- Samples that had mixed weights or had additives were not considered

- Samples from engines with less than 20,000 total miles were not considered

- Samples that did not have iron as the highest wear metal were not considered Why?

- Samples that had significant fuel or water contamination were not considered

- An attempt was made to select a balanced mix of manufacturers and engines

With this more extensive, robust analysis, it can be seen that the 20 weight oils show marginally better results for Fe, Cr, Cu, Pb, and Sn. The 30 weight oils show marginally better results for Ni and Al. How was this data normalized? That being said, neither group of oil samples is statistically different than the other. Which statistical analysis did you use? The students T method? This casts doubt on the "known" superiority of 30 weight oils, at least with these 4 cylinder engines.

Jeff_in_VABch: To answer your questions:

- This analysis is a retrospective analysis of BITOG posted UOA results. I am implying that wear metal levels are an indication of engine wear. I am not implying that they are the only indication of engine wear.

- It is not inappropriate to lump dissimilar engines together. It simply may result in larger standard deviations.

- Samples that do not have iron as the highest wear metal were excluded because the vast majority of UOAs have iron as the highest wear metal. When iron is not the highest wear metal, the analysts point out that there may be issues with the engine. I was interested in analyzing the effectiveness of 30 weight oil vs 20 weight oil in "healthy" engines.

- The data was normalized by dividing the ppm of the sample by the miles (in thousands) of the sample. For example the 1st 30 wt sample from gathermewool had an iron level of 17 ppm. Dividing 17 by 7.477 gave a normalized iron level of 2.27 ppm/1k miles.

- I did not run a student's T test on these samples. During my research career, I ran hundreds of T tests. In no case was the T test significant at the 5% level when the sample averages plus/minus 1 SD overlapped. In this case these numbers for iron are 0.77 < 1.76 < 2.75 (30 wt) and 0.74 < 1.40 < 2.06 (20 wt). If you think these two sample groups differ in a statistically significant manner, choose your level of confidence and run a student's T test and please let us know the result.

I decided to expand my analysis of wear levels demonstrated by 30 weight vs 20 weight oils in an attempt to gain greater analytical rigor.

My question would be what are we analyzing here? Are you implying we are to infer engine wear from an UOA?

It seems inappropriate to lump 4, 6, and 8 cylinder engines in the same analysis. So I will be reporting on each of these engine classes separately.

It would be inappropriate to lump any dis-similar engine together regardless of number of cylinders.

Additionally:

- There is only one reported sample for an OP/engine/oil combination

- Samples that had mixed weights or had additives were not considered

- Samples from engines with less than 20,000 total miles were not considered

- Samples that did not have iron as the highest wear metal were not considered Why?

- Samples that had significant fuel or water contamination were not considered

- An attempt was made to select a balanced mix of manufacturers and engines

With this more extensive, robust analysis, it can be seen that the 20 weight oils show marginally better results for Fe, Cr, Cu, Pb, and Sn. The 30 weight oils show marginally better results for Ni and Al. How was this data normalized? That being said, neither group of oil samples is statistically different than the other. Which statistical analysis did you use? The students T method? This casts doubt on the "known" superiority of 30 weight oils, at least with these 4 cylinder engines.

Jeff_in_VABch: To answer your questions:

- This analysis is a retrospective analysis of BITOG posted UOA results. I am implying that wear metal levels are an indication of engine wear. I am not implying that they are the only indication of engine wear.

- It is not inappropriate to lump dissimilar engines together. It simply may result in larger standard deviations.

- Samples that do not have iron as the highest wear metal were excluded because the vast majority of UOAs have iron as the highest wear metal. When iron is not the highest wear metal, the analysts point out that there may be issues with the engine. I was interested in analyzing the effectiveness of 30 weight oil vs 20 weight oil in "healthy" engines.

- The data was normalized by dividing the ppm of the sample by the miles (in thousands) of the sample. For example the 1st 30 wt sample from gathermewool had an iron level of 17 ppm. Dividing 17 by 7.477 gave a normalized iron level of 2.27 ppm/1k miles.

- I did not run a student's T test on these samples. During my research career, I ran hundreds of T tests. In no case was the T test significant at the 5% level when the sample averages plus/minus 1 SD overlapped. In this case these numbers for iron are 0.77 < 1.76 < 2.75 (30 wt) and 0.74 < 1.40 < 2.06 (20 wt). If you think these two sample groups differ in a statistically significant manner, choose your level of confidence and run a student's T test and please let us know the result.

If you accept that the "wear metals" are actual signatures of engine wear (and there is some doubt on that point) then an interesting measure to consider is "Total Wear" which is the sum of the wear metal results across each row.

Whenever I've done any trending on various oils, and I've only done a few on one or two engine types, the Total Wear number has shown much less variance than any of the individual numbers. I've had two or three (don't remember exactly after five years) graphs of Total Wear vs. distance that were straight lines with R-squared values over .95.

Based on the averages, Total Wear is 3.27 for xw-30 and 2.68 for xw-20. With this number of samples, these two results may or may not be statistically different.

Whenever I've done any trending on various oils, and I've only done a few on one or two engine types, the Total Wear number has shown much less variance than any of the individual numbers. I've had two or three (don't remember exactly after five years) graphs of Total Wear vs. distance that were straight lines with R-squared values over .95.

Based on the averages, Total Wear is 3.27 for xw-30 and 2.68 for xw-20. With this number of samples, these two results may or may not be statistically different.

- Status

- Not open for further replies.

Similar threads

- Replies

- 79

- Views

- 3K

- Replies

- 64

- Views

- 4K

- Locked

- Replies

- 360

- Views

- 18K

- Replies

- 63

- Views

- 4K