Originally Posted By: stephen9666

Originally Posted By: The Critic

I believe my old ones were the Pittsburgh Professional cro-mo ones. They are discontinued according to the HF people.

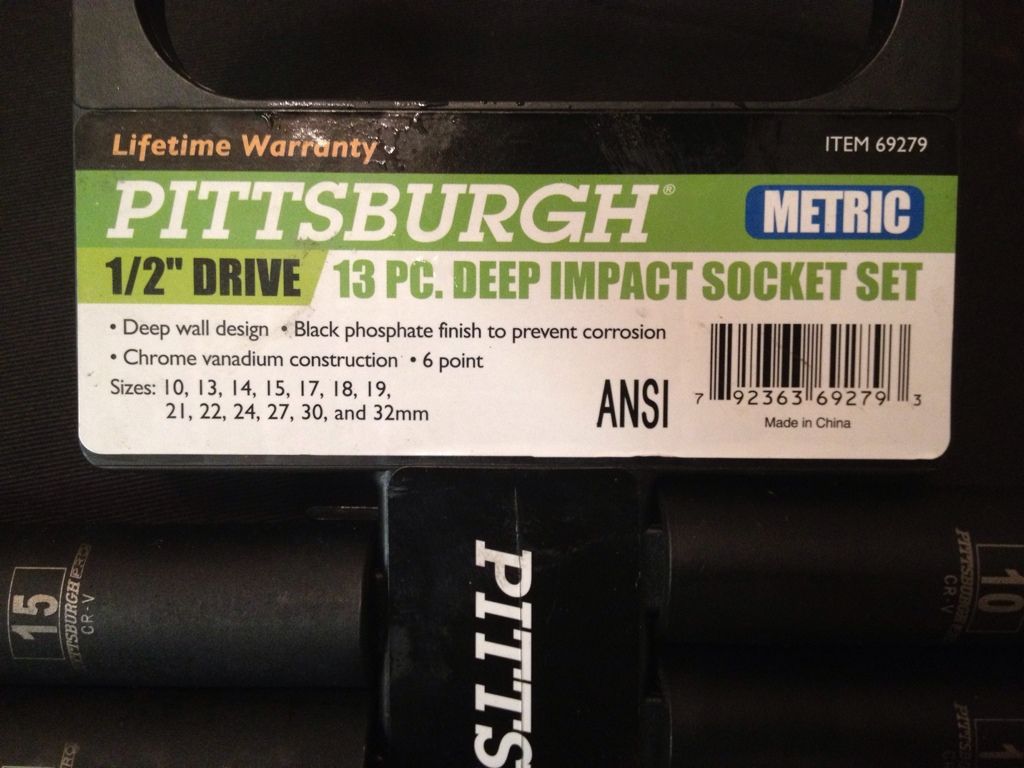

They replaced the set with this one, which is now made in China:

http://www.harborfreight.com/13-piece-hi...-set-67904.html

These have a rougher, and more dull-looking finish compared to the faintly shiny finish of the old ones.

Are your sockets stamped either "Cr-V" or "Cro-Mo?" They sometimes mark that on the sockets. Also, it appears from the pic your socket is stamped "Pittsburgh." I think the pro ones are generally marked "Pittsburgh Pro" on the sockets.

Also, how long ago did you purchase them? Pittsburgh Pro branded tools were released not too long ago.

The fact that your broken one is pretty shiny makes me believe it wasn't one of the higher-end lines, but that's just a guess.

And, the 67904 set is made in Taiwan, not China.

Perhaps the exact set you purchased has been discontinued, but the Pittsburgh Pro impact sockets aren't discontinued, I don't believe. I was there recently and they still had them. They're made in Taiwan and appear very, very similar to the impacts now sold under the Kobalt brand.

http://www.harborfreight.com/10-piece-12-drive-metric-deep-wall-impact-socket-set-67915.html

I finally got around to the pictures:

So, it looks like they have gone Chinesium with the Pittsburgh Pro impact sockets as well.

As another comparison, here is a picture of the old ones...and yes, they were the ones that came in the flimsey metal case:

Originally Posted By: Rand

That doesnt even look like an impact socket to me either.

the set I have is black phosphated(sp?) and thick wall.

Thats thin and painted?

Yeah, the one that I broke came from the flimsy metal case....they are definitely impact sockets but have a dull, smooth finish.