- Joined

- Jan 10, 2014

- Messages

- 132

We all know more than the engineers that designed our engines….right?

Certified from YouTube University. I went with the BS degree.

We all know more than the engineers that designed our engines….right?

I think watching another 90-120 YouTube videos on the same topic would earn you the MS degree...Certified from YouTube University. I went with the BS degree.

No idea. Just using the pic as a good example of upper rod bearing wear.

Did you even read my post? I made it 110% clear I was using the photo to show what upper rod bearing wear looks like. Sometimes I really wonder why anyone including myself share experiences here….So you have no idea what engine they're from, what oil was used, how many miles on them, or the use case... But are sure that thicker oil would have prevented it.

That is not quite what Glenda said or implied.So you have no idea what engine they're from, what oil was used, how many miles on them, or the use case... But are sure that thicker oil would have prevented it.

Eveyrtime I see your posts/, I think of this picture from a trip out to CA a while ago. Unrleated but whatever.I guess I need to explain my post better. Sometimes when dissembling an engine for inspection you will find wear on the upper rod bearing halves(like shown below) and no wear at all on the bottom half. What causes this is during TDC of the power stroke energy travels down the connecting rod to the crank. This squeezes the oil “cushion” between the crank journal and upper rod bearing half. If oil temperatures get to hot and viscosity is to low this cushion could go to zero causing friction and wear. This is common during severe service like racing, towing, plowing etc. and the reason why some manufacturers recommended a higher viscosity in severe service. Something like oil starvation usually causes wear to upper and lower rod bearings.

View attachment 266546

Before I retired - I replaced ring sets on a few dozen high mileage, 3.5 V6 Honda engines.I guess I need to explain my post better. Sometimes when dissembling an engine for inspection you will find wear on the upper rod bearing halves(like shown below) and no wear at all on the bottom half. What causes this is during TDC of the power stroke energy travels down the connecting rod to the crank. This squeezes the oil “cushion” between the crank journal and upper rod bearing half. If oil temperatures get to hot and viscosity is to low this cushion could go to zero causing friction and wear. This is common during severe service like racing, towing, plowing etc. and one reason why some manufacturers recommended a higher viscosity in severe service. Something like oil starvation usually causes wear to upper and lower rod bearings.

View attachment 266546

Those are great engines, my daughter’s 2016 RDX has one. I use 0w30 and it’s never burned a drop of oil, knock on wood.Before I retired - I replaced ring sets on a few dozen high mileage, 3.5 V6 Honda engines.

And a few piston/ring sets on high mileage 2.4K engines.

All due to carbon locked rings - under extended warranty. All used Xw20 oil, the majority were 0w20.

I can report none had upper bearing wear as shown.

But I'm pretty sure none were driven at the track either.

Yes it is - the ring sticking problem was something that I never saw a clear reason for.Those are great engines, my daughter’s 2016 RDX has one. I use 0w30 and it’s never burned a drop of oil, knock on wood.

Or spark knocking….Rod bearing uppers? Looks like some lugging, is this a manual transmission vehicle?

Low tension piston rings and longer OCI’sYes it is - the ring sticking problem was something that I never saw a clear reason for.

Obviously the VCM shutting down the cylinders was the main culprit - but so many never had a problem.

The K motor rings sticking were much more rare.

I've always thought (conjectured) it was a combination of bare minimum maintenance, and Starvin' Marvin fuel.

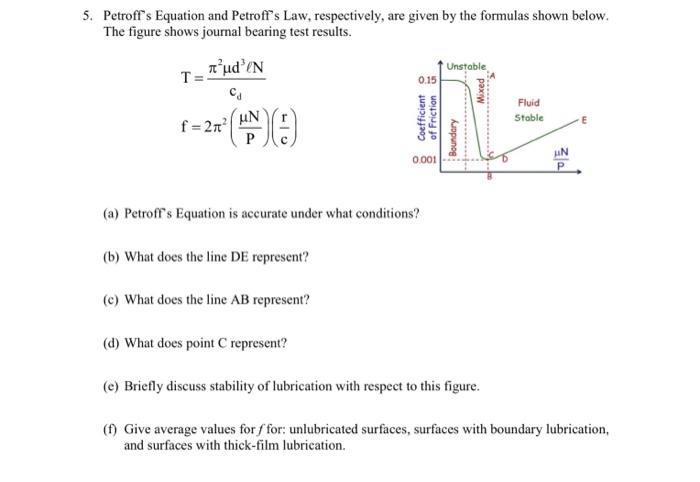

What is this 3 factor bearing graph that you speak of like its eveyday knowledge? Is it the 3 ball Amsoil test that proves nothing in the real world?

That's a contributing factor, but there's more to it than that.Low tension piston rings and longer OCI’s

There was a time in my life when I thought I could assemble and install a small or big block Chev blindfolded.Did you even read my post? I made it 110% clear I was using the photo to show what upper rod bearing wear looks like. Sometimes I really wonder why anyone including myself share experiences here….

I know the feeling!! Then you of all people know what it’s like to pull a SBC pan to inspect rod bearings. Never pull just the cap, inspect the upper half too. Also I have no doubt you could do it blindfolded. I never mentioned the engine but you knew!There was a time in my life when I thought I could assemble and install a small or big block Chev blindfolded.

Without getting too high on my own supply, the answer is yes.

Especially that upper one !I know the feeling!! Then you of all people know what it’s like to pull a SBC pan to inspect rod bearings. Never pull just the cap, inspect the upper half too. Also I have no doubt you could do it blindfolded. I never mentioned the engine but you knew!

Double major, but still BS.I think watching another 90-120 YouTube videos on the same topic would earn you the MS degree...

Right. The upper rod bearing is the loaded one and sensitive to over loading from detonation, high boost or bringing in the NOS at low rpm without enough camshaft to bleed off torque.Especially that upper one !

There's a ton of multi run analysis threads and even ones comparing 30 and 20 in the same engine.If only that were the case. Singular uncontrolled UOA aren’t nearly as useful as many imagine them to be.