Firstly, if in the wrong subforum please move.

Short version, dropped a bolt, couldn't find it, replaced with a stainless analog from Lowe's.( Different head, but right thread and length)

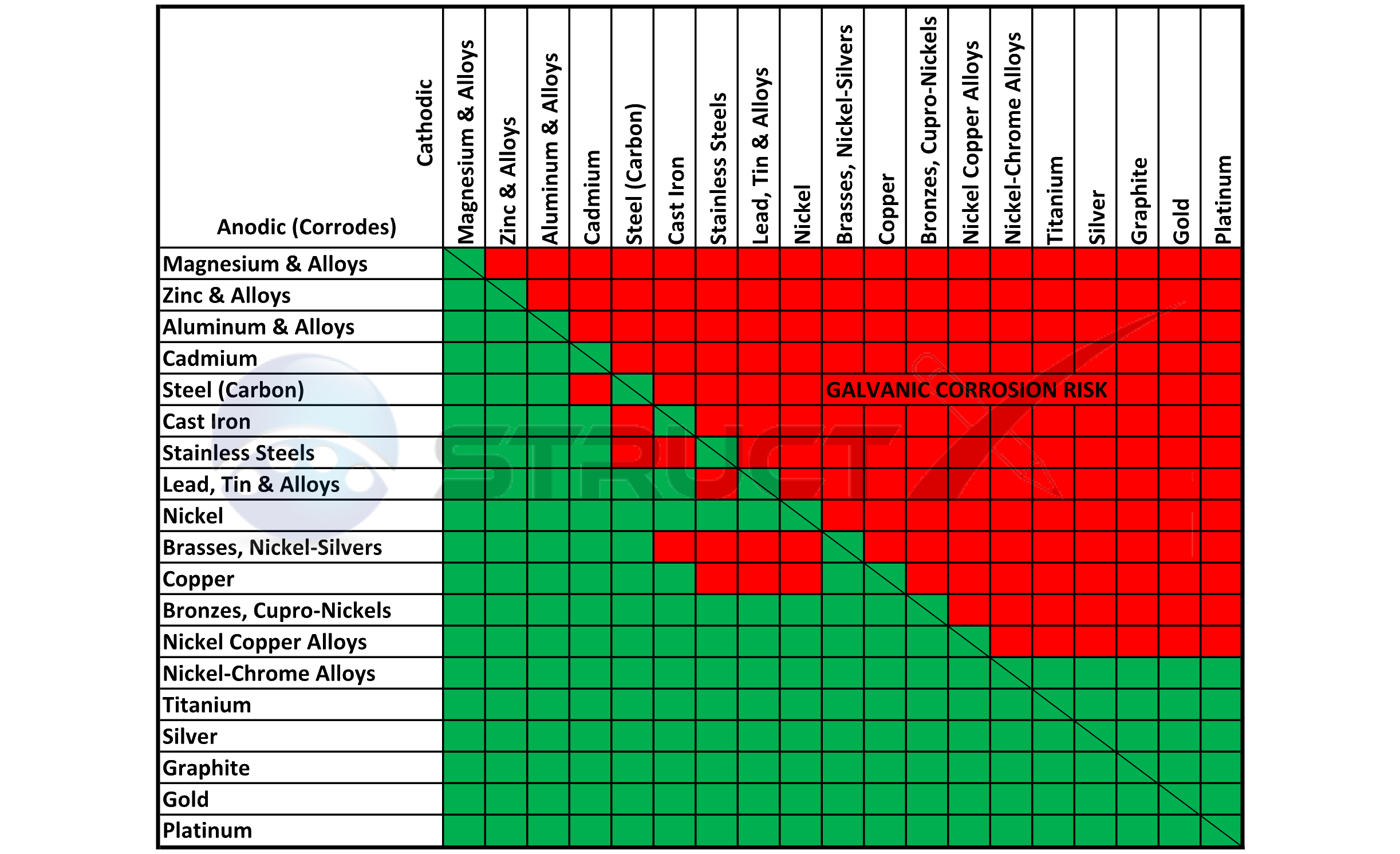

Do I need to worry about anything putting stainless fasteners into an Al housing?

Factory bolt is a flange bolt w/ an 8mm hex head, the ones I bought are cap screws, take a 5m Allen key...

Short version, dropped a bolt, couldn't find it, replaced with a stainless analog from Lowe's.( Different head, but right thread and length)

Do I need to worry about anything putting stainless fasteners into an Al housing?

Factory bolt is a flange bolt w/ an 8mm hex head, the ones I bought are cap screws, take a 5m Allen key...