- Joined

- Nov 7, 2022

- Messages

- 7

I know there are numerous threads on why NOT to oil the bolts. Too late for that.

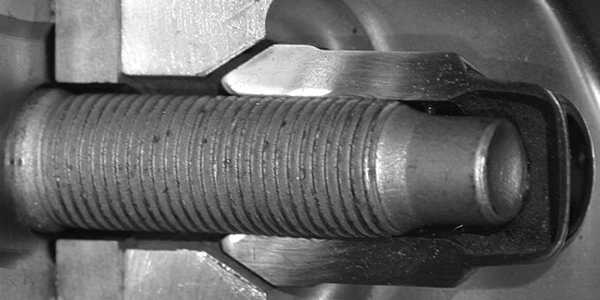

After wire brushing off the rust, I sprayed the bolts with some Seafoam Deep Creep to get remaining rust off, then carefully wiped the threads off with paper towel. I'm realizing now that I can't simply wipe away oil and there is likely a significant residue and that I should probably remove and clean bolts and inner threads with brake fluid. Am I being over cautious to remove and clean with brake fluid, or being stupid if I don't?

After wire brushing off the rust, I sprayed the bolts with some Seafoam Deep Creep to get remaining rust off, then carefully wiped the threads off with paper towel. I'm realizing now that I can't simply wipe away oil and there is likely a significant residue and that I should probably remove and clean bolts and inner threads with brake fluid. Am I being over cautious to remove and clean with brake fluid, or being stupid if I don't?