Originally Posted By: severach

My understanding is that old hydraulic lifters under pressure leak down over several hours. Valves on those lifters have low rise until fresh oil pressure raises them to their correct height. The low rise valves inhibit starting. Auto-RX might help this.

Solid lifters raise every valve to its full height the first time and every time.

All of my cars start just fine. The difference is that just fine for solid lifters is a quick snap of the starter even when the engine is off all night in the cold winter. The cylinder partially through it's intake stroke will have full valve height and pulls enough charge to fire. One out of every 50 starts may require more than a half a revolution. It's so rare that I think something is broken when it doesn't fire with a starter snap. Failure on the second snap and I'm under the hood tightening things up. After a while you learn the minimum snap it takes to start almost every time. One solid lifter engine started so well that when warm there was no minimum snap. Even kerchunking the starter to move the flywheel it would start most of the time. I had to disconnect the distributor.

Just fine for hydraulic lifters is 2 or more revolutions because the cylinder on intake had its intake lifter smooshed all night so that one probably won't fire. Some other cylinders are lame too. Crank and crank until you can find a cylinder that will cooperate. Snap starting is so rare that you just unlearn the habit. I'm glad to see that car companies are still producing engines suitable for OCD maintenance.

I've started carb, FI, 4, 6, 8 cylinders, and diesels and the only common link I could see for starting speed was hydraulic vs solid lifters.

***

There isn't any drag. Pick any valve that is fully released. You might rotate the engine back and forth to ensure that the valve is definitely released and not sitting on the edge of its cam lobe. Select the feeler in the middle of the range, loosen the lock nut, screw the height adjustment until it touches the feeler, then tighten the lock nut. Watch the screw head to ensure that tightening the lock nut doesn't move it. Rotate the engine back and forth ensuring that the feeler gets no looser or tighter from the valve being on the edge of its cam lobe. Rotate the engine to get more valves to release.

The pump-up on a hydraulic lifter is only a few thou, not enough to cause the valves to not open an adequate amount. Both my small block Ford's start in 1/2 a turn and they are both hydraulic roller. The camshaft would have to be a BROOMSTICK for the lifter pump-up to be an issue, as I said, they are simply a hydraulic LASH adjuster, they are there to keep pre-load on the pushrod. There have been cases where the lifter has FULLY pumped up (become a solid basically) and WILL hang the valves OPEN. They are not meant to pump up all the way, that is NOT how they work. They are set with an amount of pre-load on them (remember, they are spring-loaded as well) and then the pressure of the oil acts as a "cushion" to maintain the lash on the lifter and prevent valve-train noise.

They are not as "instant" as a solid roller or solid flat tappet lifter, because of the "cushion" the oil provides, but in no way does that affect how the engine starts unless we are talking about some broomstick camshaft with no lift that has been improperly setup.

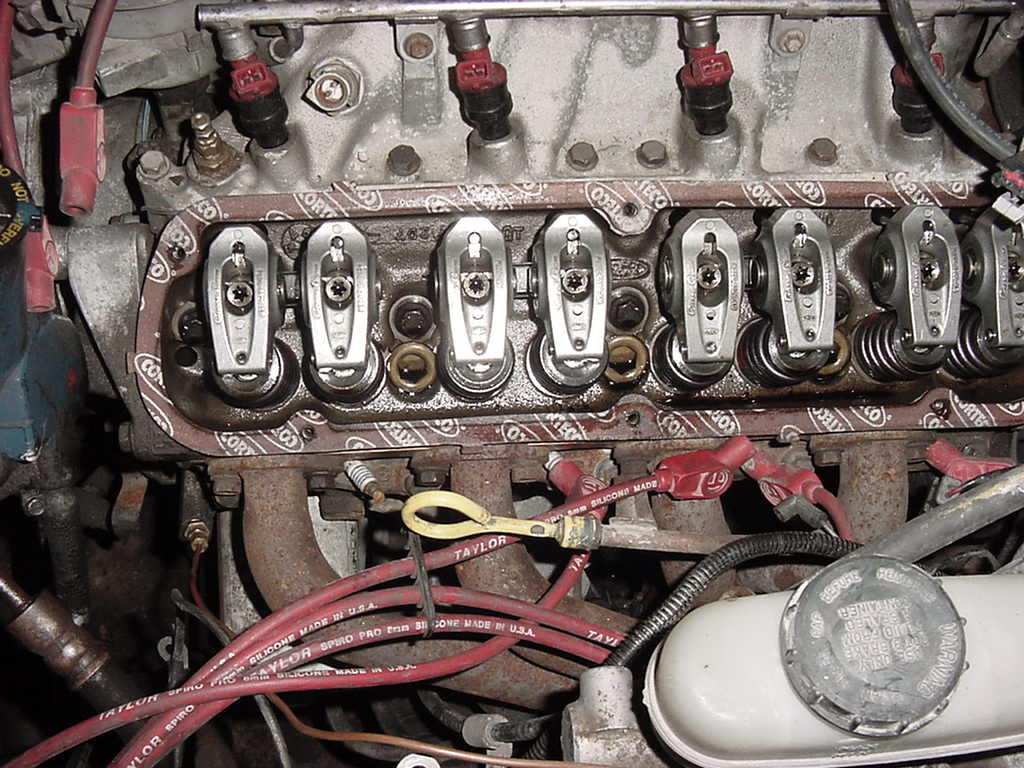

I want you to look at this picture:

Can you tell that #7 is open? That engines has not been run in THREE YEARS!!!!!!!!!! That lifter is never going to get any less pumped-up. And that lifter is not even on the top of the lobe! Those springs are 400#'s open as well. They are being replaced with 500's.

The plunger travel on a hydraulic lifter is not going to make our break whether an engine starts. As I said, it's a form of lash adjustment which is why a hydraulic valve train, when properly setup, never needs adjustment. A solid setup, especially solid roller on a cam-in-block design definitely has it's merits, as the lifters are light, the response at the rocker is instant, and the camshaft profile can be far more aggressive. But this has no bearing on how fast the engine starts.

Fuel delivery, ignition system, compression ratio, ignition timing....etc THOSE things can and do play a big roll in how an engine starts.