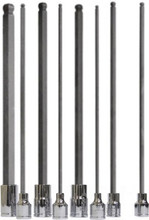

I have a new set of these - what are they used for?

Hex head bolts are sketchy enough as is - I can't imagine using one of these to break one loose.

You can always make a short reach socket longer, by stacking on extensions. But it's hard to make a too long hex shorter--well, you can, but only once. And in this case, maybe not even.I guess I can see a use for a set of long ball hex sockets. But short ones? I'm a little skeptical.

I'll probably throw these up for sale at some point.

I have them in a few sizes. I use them when I have no other choice. Be prepared to replace the bolt after breaking it loose with force.View attachment 145231

I have a new set of these - what are they used for?

Hex head bolts are sketchy enough as is - I can't imagine using one of these to break one loose.

The longer ones are more useful for going in at an angle.$243? Are they gold plated?