You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Would you sacrifice engine life......

- Thread starter expat

- Start date

- Status

- Not open for further replies.

Originally Posted By: Joenpb

Originally Posted By: omegaspeedy

This has been a long thread of of many opinions for and against low viscosity oils (some backed up with scientific papers).

So should we run a full synthetic 5W40 or an 0W20 (mild conditions) in a modern 2.0L Variable Valve Timing Cam engine to MINIMISE WEAR. I don't give a rats [censored] about fuel economy. The user manual states both are acceptable.

Still fully confused...

Use each for an OCI and do a UOA on both, then make your decision based on fact/wear, as opposed to unsubstantiated claims. Good luck.

LOL. You can't be serious right?

Originally Posted By: omegaspeedy

This has been a long thread of of many opinions for and against low viscosity oils (some backed up with scientific papers).

So should we run a full synthetic 5W40 or an 0W20 (mild conditions) in a modern 2.0L Variable Valve Timing Cam engine to MINIMISE WEAR. I don't give a rats [censored] about fuel economy. The user manual states both are acceptable.

Still fully confused...

Use each for an OCI and do a UOA on both, then make your decision based on fact/wear, as opposed to unsubstantiated claims. Good luck.

LOL. You can't be serious right?

- Joined

- Dec 30, 2006

- Messages

- 29,558

Originally Posted By: omegaspeedy

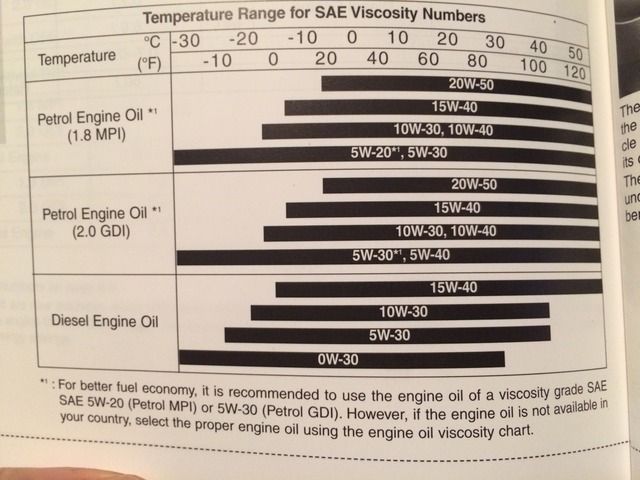

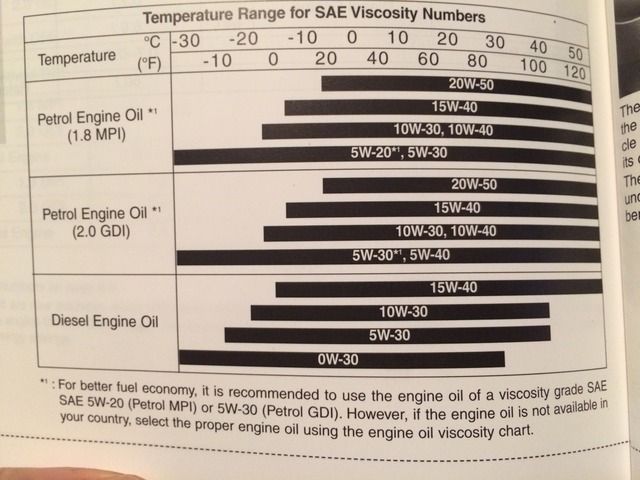

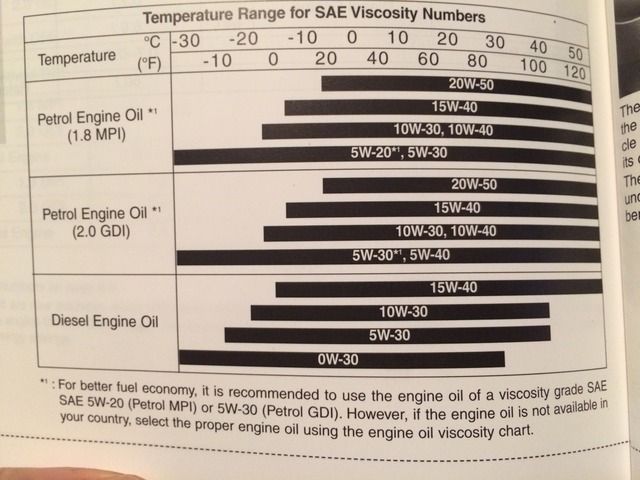

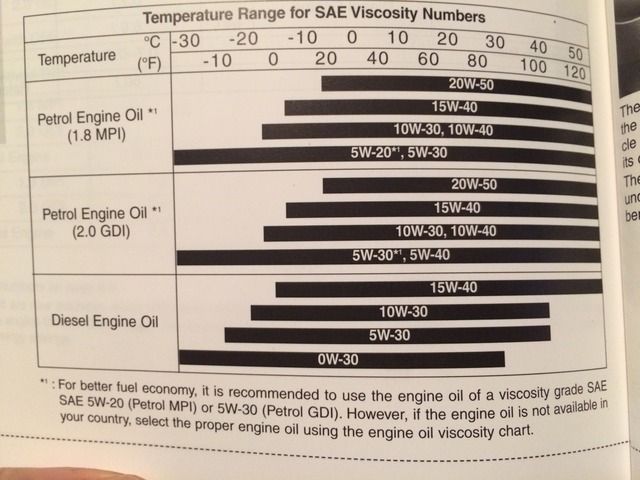

So here's my user guide. Should I move away from the recommendation of using a 5W30 or 5W40 (2.0L GDI) and move to a 0W20 because it will give me better protection at start up and overall better wear resistance?

As stated in your owner's manual,5W20-5W30 are for fuel economy. 10W30-20W50 are for optimum engine protection.

So here's my user guide. Should I move away from the recommendation of using a 5W30 or 5W40 (2.0L GDI) and move to a 0W20 because it will give me better protection at start up and overall better wear resistance?

As stated in your owner's manual,5W20-5W30 are for fuel economy. 10W30-20W50 are for optimum engine protection.

Originally Posted By: omegaspeedy

So here's my user guide. Should I move away from the recommendation of using a 5W30 or 5W40 (2.0L GDI) and move to a 0W20 because it will give me better protection at start up and overall better wear resistance?

Who says you get better protection and wear resistance?

Your manufacturer only talks of Fuel saving.

They do not mention 0w-20 at all, and while they accept 0w-30 for the Diesel engine they put an upper temp limit on it.

So here's my user guide. Should I move away from the recommendation of using a 5W30 or 5W40 (2.0L GDI) and move to a 0W20 because it will give me better protection at start up and overall better wear resistance?

Who says you get better protection and wear resistance?

Your manufacturer only talks of Fuel saving.

They do not mention 0w-20 at all, and while they accept 0w-30 for the Diesel engine they put an upper temp limit on it.

Last edited:

expat, note 1 on the table talks about "for best fuel economy use a 5W30". I assumed the rest are not for best fuel economy and thinking higher grades = stronger film strength and less metal to metal contact during high work?

I drive old cars. I know that the bull about the grade 20 oil is just a myth to please the eco-crowd and... help boost the new car sales numbers (without liability of a recall).

A car manufacturer doesn't care about wear resistance past the warranty period.

My 2001 Sonata is 'treated' with 5W40 Rotella T6.

A car manufacturer doesn't care about wear resistance past the warranty period.

My 2001 Sonata is 'treated' with 5W40 Rotella T6.

Last edited:

I drive new cars...and I can tell you that I have a Hyundai GDI engine and would be at least cognizant of the NOACK/TEOST/SAPS numbers versus running a 5w-40 with a NOACK of 14.5 and dreaming about how much better I'm being protected it while [censored] gas and valve deposits eventually cause an $800 repair.

Originally Posted By: omegaspeedy

So here's my user guide. Should I move away from the recommendation of using a 5W30 or 5W40 (2.0L GDI) and move to a 0W20 because it will give me better protection at start up and overall better wear resistance?

How much wear resistance you gonna get when that 0W-20 gets up to 148 degrees Celsius? (300 F).

It may be the ideal thickness when cold, but it gets thinner and thinner as it heats up.

And if thinner oils are so good for startup, then why is engine assembly lube so thick?

So here's my user guide. Should I move away from the recommendation of using a 5W30 or 5W40 (2.0L GDI) and move to a 0W20 because it will give me better protection at start up and overall better wear resistance?

How much wear resistance you gonna get when that 0W-20 gets up to 148 degrees Celsius? (300 F).

It may be the ideal thickness when cold, but it gets thinner and thinner as it heats up.

And if thinner oils are so good for startup, then why is engine assembly lube so thick?

Originally Posted By: Joenpb

Use each for an OCI and do a UOA on both, then make your decision based on fact/wear, as opposed to unsubstantiated claims. Good luck.

What would such UOAs tell you, and what is your source that subsequent, single data point UOAs on different products are valid ways to measure wear?

Originally Posted By: Merkava_4

How much wear resistance you gonna get when that 0W-20 gets up to 148 degrees Celsius? (300 F). It may be the ideal thickness when cold, but it gets thinner and thinner as it heats up. And if thinner oils are so good for startup, then why is engine assembly lube so thick?

Merk, that is strawman after strawman. You'll still be under hydrodynamic lubrication if the 0w-20 is at temperature and the engine is permitted to run 0w-20. Secondly, it's not the ideal thickness when cold. As for assembly lube, you know exactly why it's so thick. It must adhere to new parts. Carrying on the strawman argument, why don't you disassemble your engine each night and slather it with assembly lube before you go to bed?

Use each for an OCI and do a UOA on both, then make your decision based on fact/wear, as opposed to unsubstantiated claims. Good luck.

What would such UOAs tell you, and what is your source that subsequent, single data point UOAs on different products are valid ways to measure wear?

Originally Posted By: Merkava_4

How much wear resistance you gonna get when that 0W-20 gets up to 148 degrees Celsius? (300 F). It may be the ideal thickness when cold, but it gets thinner and thinner as it heats up. And if thinner oils are so good for startup, then why is engine assembly lube so thick?

Merk, that is strawman after strawman. You'll still be under hydrodynamic lubrication if the 0w-20 is at temperature and the engine is permitted to run 0w-20. Secondly, it's not the ideal thickness when cold. As for assembly lube, you know exactly why it's so thick. It must adhere to new parts. Carrying on the strawman argument, why don't you disassemble your engine each night and slather it with assembly lube before you go to bed?

"sequence IV warm-up test"

Please tell us what this is, thanks.

aehaas

Please tell us what this is, thanks.

aehaas

Originally Posted By: Garak

As for assembly lube, you know exactly why it's so thick. It must adhere to new parts.

Ah Ha! I reeled you in on that one.

Don't you think a thicker oil would be closer to an assembly lube on startup than 0W-20 would?

Don't you think a thicker oil would be closer to an assembly lube on startup than 0W-20 would?

I caught me a supersized Marlin this time.

I caught me a supersized Marlin this time.

As for assembly lube, you know exactly why it's so thick. It must adhere to new parts.

Ah Ha! I reeled you in on that one.

No, you didn't. I said new parts, not parts that are in an engine that runs and has been running. New parts aren't lubricated for operation when shipped, so they must be lubricated at installation. When I shut my engine off, regardless of the viscosity, no matter how long I leave it, there will be an oil film on all parts. If you like it being close to an assembly lube on startup, try a 10w-30 up here when it falls to -40. Tell me how much fun you have.

It's not wishful thinking. It's a fact. I'm not saying it's sufficient to protect from all wear no matter what (we all know that's what Slick 50 and other snake oils are for). I'm saying that I've never disassembled an engine, no matter how long it's sat, and found any of the components to be dry of oil.

Originally Posted By: AEHaas

"sequence IV warm-up test"

Please tell us what this is, thanks.

aehaas

It's one of the engine tests that are required for an API licenced oil. The tests are tabled here.

The test is designed to test the oil's ability to protect during the warm-up phase where the bulk of wear occurs. Engine is running, and the oil flow is fully established, but the temperatures are controlled to a point that while the viscosity is dropping, the temperatures are not conducive to strong additive function.

Description of the test times and temperatures can be found here.

If the much vaunted "flow" of thinner oils provided better warmup protection, then clearly, it would be an advantage in the industry standard warm-up wear test, but it doesn't appear to have any supportive evidence, and the API seem to have reservations also.

Here are the API base oil interchange guidelines that I referenced earlier. Table E4 is the interchange rule for the Sequence IVA testing, and as can be seen, a basestock can only be interchanged if the finished viscosity is greater than/equal to the tested viscosity. So if an oil is qualified as a 5W30, and the same package used to make a 5W40, no Sequence IV test is required. If I make a 5W20 with the same package, then the test is required to be performed.

A really good discussion can be found here, with some professionals who actually do the testing.

For completeness, here's a discussion I kicked off on what happens during warm-up a few months ago that might help explain why the sequence IVA uses the temperatures that it does.

Member bobbydavro made this statement in the thread.

Originally Posted By: bobbydavro

All makes sense and I have ran the IVA at lower temperatures and see lower numbers so it is defiantly on the sweet spot of wear.

"sequence IV warm-up test"

Please tell us what this is, thanks.

aehaas

It's one of the engine tests that are required for an API licenced oil. The tests are tabled here.

The test is designed to test the oil's ability to protect during the warm-up phase where the bulk of wear occurs. Engine is running, and the oil flow is fully established, but the temperatures are controlled to a point that while the viscosity is dropping, the temperatures are not conducive to strong additive function.

Description of the test times and temperatures can be found here.

If the much vaunted "flow" of thinner oils provided better warmup protection, then clearly, it would be an advantage in the industry standard warm-up wear test, but it doesn't appear to have any supportive evidence, and the API seem to have reservations also.

Here are the API base oil interchange guidelines that I referenced earlier. Table E4 is the interchange rule for the Sequence IVA testing, and as can be seen, a basestock can only be interchanged if the finished viscosity is greater than/equal to the tested viscosity. So if an oil is qualified as a 5W30, and the same package used to make a 5W40, no Sequence IV test is required. If I make a 5W20 with the same package, then the test is required to be performed.

A really good discussion can be found here, with some professionals who actually do the testing.

For completeness, here's a discussion I kicked off on what happens during warm-up a few months ago that might help explain why the sequence IVA uses the temperatures that it does.

Member bobbydavro made this statement in the thread.

Originally Posted By: bobbydavro

All makes sense and I have ran the IVA at lower temperatures and see lower numbers so it is defiantly on the sweet spot of wear.

Originally Posted By: SoNic67

Originally Posted By: Garak

When I shut my engine off, regardless of the viscosity, no matter how long I leave it, there will be an oil film on all parts.

That's called wishful thinking.

I've never been able to pull apart an engine, even one that's been sitting for a year without getting covered in oil. Pistons, rings, bearings, rocker assemblies all hold some oil.

edit...Garak beat me.

Originally Posted By: Garak

When I shut my engine off, regardless of the viscosity, no matter how long I leave it, there will be an oil film on all parts.

That's called wishful thinking.

I've never been able to pull apart an engine, even one that's been sitting for a year without getting covered in oil. Pistons, rings, bearings, rocker assemblies all hold some oil.

edit...Garak beat me.

Last edited:

Originally Posted By: Garak

When I shut my engine off, regardless of the viscosity, no matter how long I leave it, there will be an oil film on all parts.

But don't you have a thicker film thickness left behind if the oil you're using is thicker?

When I shut my engine off, regardless of the viscosity, no matter how long I leave it, there will be an oil film on all parts.

But don't you have a thicker film thickness left behind if the oil you're using is thicker?

Originally Posted By: AEHaas

"sequence IV warm-up test"

Please tell us what this is, thanks.

aehaas

I did some digging around on Seq IVA test results. Here is what I found.

The Seq IVA SN pass limit is 90 microns. This is also the proposed standard for GF-6A & GF-6B.

Ravenol 0w-16 measured 24 microns.

Source: http://www.ravenol.de/fileadmin/content/documents/pdfs/Ravenol_EFE_SAE_0W-16__en.pdf

According to Selda Gunsel, Manager, Lubricants Technology Group, Shell Global Solutions (US) Inc:

"considering that one standard deviation from the mean in the test is 12.5, there is no statistically significant difference for test results within 35 microns of each other."

Here are the results of Seq IVA testing in 2009 on three 5w30's. M1 is the unmarked, problematic one.

As you can see, a 0w-16, like Ravenol, is statistically indistinguishable from major brand 5w-30 full synthetics.

Source: http://www.jobbersworld.com/March%2020,%202009.htm

"sequence IV warm-up test"

Please tell us what this is, thanks.

aehaas

I did some digging around on Seq IVA test results. Here is what I found.

The Seq IVA SN pass limit is 90 microns. This is also the proposed standard for GF-6A & GF-6B.

Ravenol 0w-16 measured 24 microns.

Source: http://www.ravenol.de/fileadmin/content/documents/pdfs/Ravenol_EFE_SAE_0W-16__en.pdf

According to Selda Gunsel, Manager, Lubricants Technology Group, Shell Global Solutions (US) Inc:

"considering that one standard deviation from the mean in the test is 12.5, there is no statistically significant difference for test results within 35 microns of each other."

Here are the results of Seq IVA testing in 2009 on three 5w30's. M1 is the unmarked, problematic one.

As you can see, a 0w-16, like Ravenol, is statistically indistinguishable from major brand 5w-30 full synthetics.

Source: http://www.jobbersworld.com/March%2020,%202009.htm

I don't know, Merk. There is a lot more to film thickness on a stationary part than simple viscosity. There are several factors that would play a part. Additionally, how much benefit does this film actually provide, and how does the thickness of this film affect that benefit? Saying that a thicker oil automatically leaves a thicker film and a thicker film is automatically better at startup makes a series of assumptions without any data to back them up.

Assembly lube, as per your example, is loaded with goodies. If you just want something thick, petroleum jelly or grease would be just as good, right?

Assembly lube, as per your example, is loaded with goodies. If you just want something thick, petroleum jelly or grease would be just as good, right?

Originally Posted By: Garak

Originally Posted By: Joenpb

Use each for an OCI and do a UOA on both, then make your decision based on fact/wear, as opposed to unsubstantiated claims. Good luck.

What would such UOAs tell you, and what is your source that subsequent, single data point UOAs on different products are valid ways to measure wear?

UOAs can validate the amount of wear metals of an OCI in comparison to the averages for same vehicle/engine. Helpful if you're using a viscosity not recommended by the manufacturer. Making an assumption that a higher viscosity oil will always provide more protection and less wear metals is not always correct.

Originally Posted By: Joenpb

Use each for an OCI and do a UOA on both, then make your decision based on fact/wear, as opposed to unsubstantiated claims. Good luck.

What would such UOAs tell you, and what is your source that subsequent, single data point UOAs on different products are valid ways to measure wear?

UOAs can validate the amount of wear metals of an OCI in comparison to the averages for same vehicle/engine. Helpful if you're using a viscosity not recommended by the manufacturer. Making an assumption that a higher viscosity oil will always provide more protection and less wear metals is not always correct.

- Status

- Not open for further replies.

Similar threads

- Locked

- Replies

- 183

- Views

- 11K

- Replies

- 63

- Views

- 4K

- Sticky

- Replies

- 3

- Views

- 2K

- Replies

- 26

- Views

- 3K