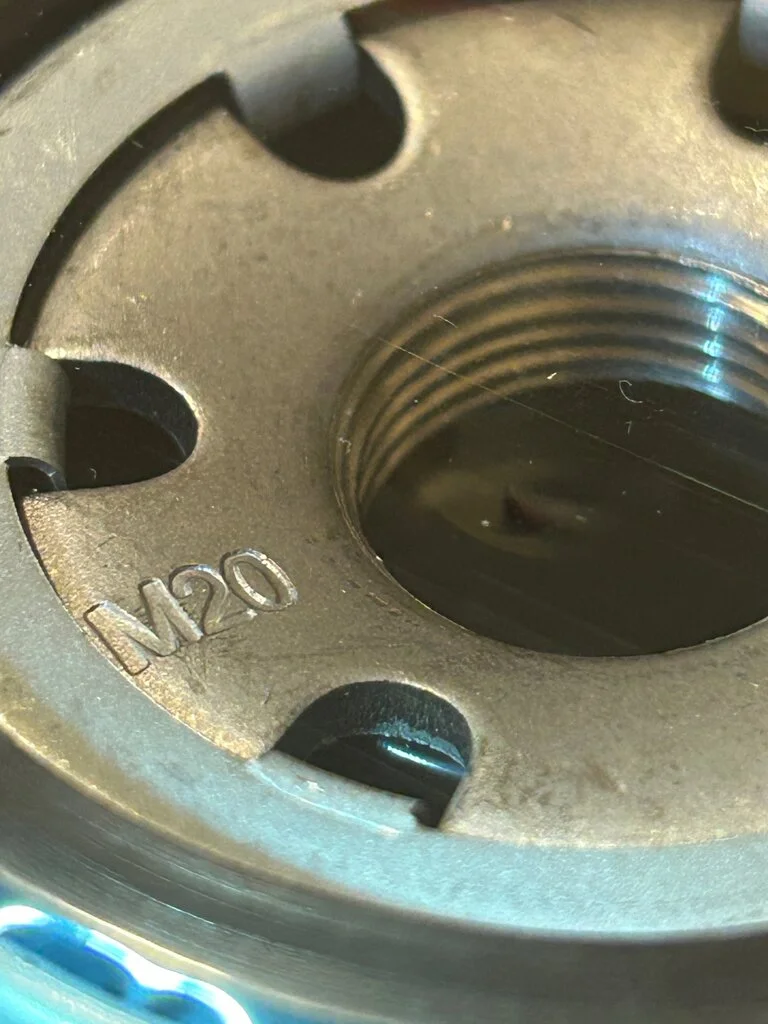

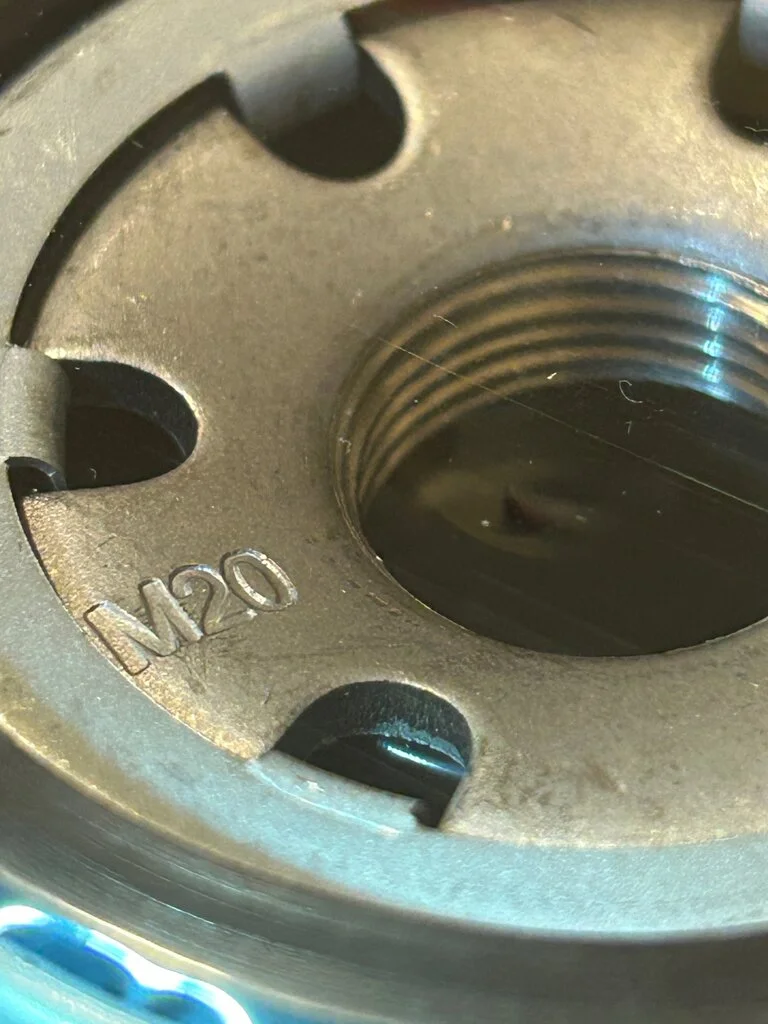

Never seen construction like this - not sure what you call this levered over tab crimp on construction for the base plate. Not that it matters, just have never seen this before.

This is a cross for the ubiquitous 7317 size Nissan / Honda filter, FYI.

This is a cross for the ubiquitous 7317 size Nissan / Honda filter, FYI.