I made up a few quick and dirty ideas for your galleries down in the block – and I didn't make any bold. The main point there was that a first (in time more than in space) partial flow getting going, for example shearing in entrainment and warming the environment somewhere in the branched, the dendritic... system (whatever the black box, providing the PD like performance resembling real world pumping, may be hiding): will be a form of relief occurring at say 12.84 psig. Aiding further delay for the remaining lubrication points.

Next in repetition: Whatever the pressure relief action, 40 psig were not the problem. We spoke about it although that's been about down in a gallery of a pushrod engine. The links are also there, not just the tables, turn the page and read on if you're developing the interest now.

But I'm not that good at repeating repetition over and over again to follow in ever more ignorant ping pong.

I had mentioned pushrods and lifters, found table 3 for pushrod testing and shared the table and link. These people extended on the question of suction side pumpability – just consider reading as many of the 14 pages as you please, please. The pic itself of course made sufficiently clear what they deemed statistically relevant or not. And that table 3 with its paragraph was about pressure side pumpability. Skim the rest and find them mentioning "high" shear viscosity ;-)

Let me try the bold myself:

You're not going to tell me that in two minutes of noise to 40 psig there'd be cavitation / vacuum / air binding for their typical five minutes of dry rocking behind the pushrods and that they, although fully aware of pump screens and whistles, didn't get the idea.

40 psig is real world. Designed pressure relief, bypass and more additional designed pressure relief are real world.

Your ideas of pressure missing at the gallery to explain the vast additional delay between there and up in the rock house are in no way supported by the findings. Check it out for yourself.

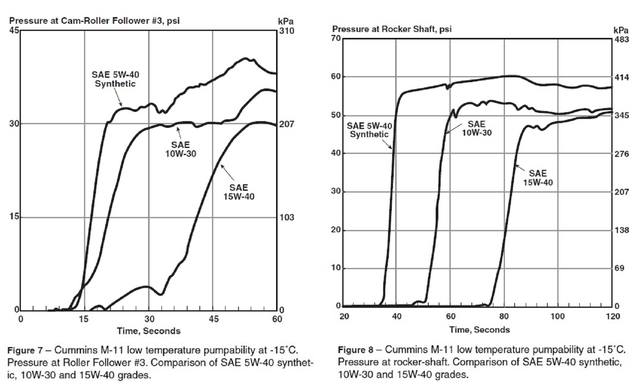

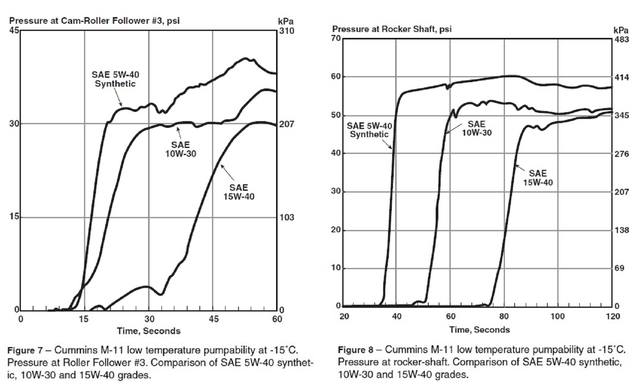

Thanks to the previous thread you need not even revolve around the -20°F at all if you don't want to: The -15°C didn't result in the same delays of course but still result in an easy +100% recorded for rocker arms. 15w40 in -15°C according to traditional positive displacement & J300 threads on here is correct oil choice and probably not on any ragged edge.

Either way, again the delay is so much more pronounced in some areas than in others. Seven- to tenfold at the rocker shafts. The Cummins may not even have used hollow pushrods but a gallery to the rockers, that one I should look up.

That's dendritics, ramifications, branches, Ockhams Rasiermesser and rock out.

I shall really see where I can find fresh and independent data for you while you're developing your interest in exploring what you've been shown. Ah, the maieutics...

He could even point Project Farm to persistant video demand in that area – at least until the day you feel funny and start explaining where and how your ideas were ...developed.