- Joined

- Sep 26, 2010

- Messages

- 9,837

I have a couple of Metal Cloak axle covers that I will be drilling and tapping for a temperature probe soon. The rear axle I have fully figured out and know where to install the probe for a good temperature reading while the axle is in operation.

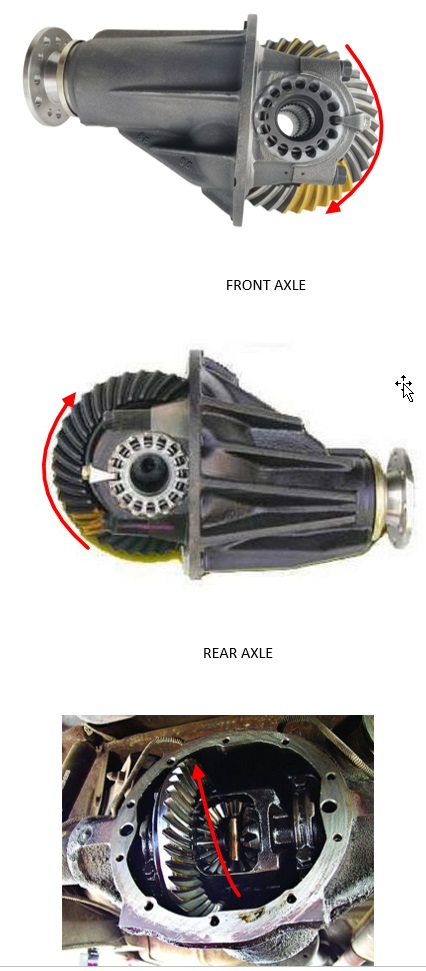

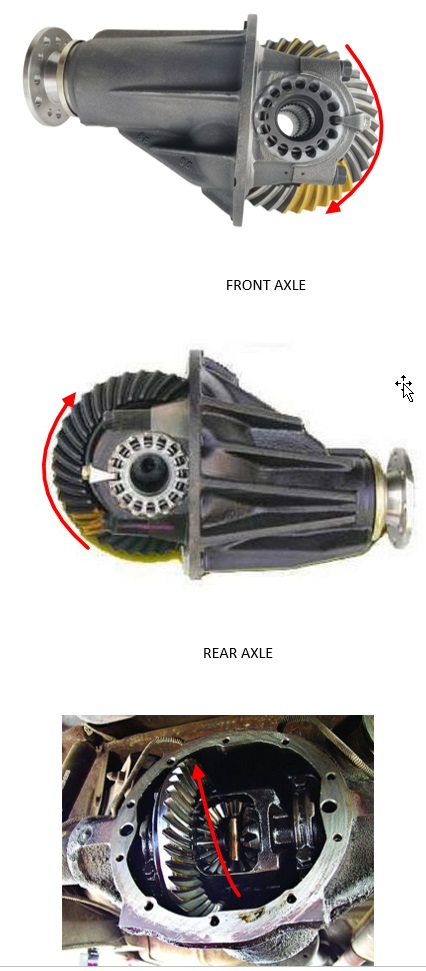

Note: these photos are for representation purposes only (these not my axles, though I do have a high pinion in the front and low pinion in the rear as shown).

Taking into account the ring gear rotation direction of the rear axle, the arrow on the bottom photo is typically the path the oil takes from the bottom of the housing and over the top of the ring gear. The temperature sensor is located in the axle cover about where the end of the red arrow ends and the temperature reading is steady while the axle is in motion.

The front axle is where I am scratching my head a little. Part of the problem is there is a front axle disconnect which prevents the ring gear and driveshaft from spinning while in 4x2 mode. I have not been able to get out and into 4x4 mode for any length of time since C19 hit. The few times that I have been in 4x4, the temperature gauge seems to read, but I want to be sure that where I have the sensor located (same place as the rear) is optimum.

My question is this—does the oil in the front axle follow the same path (but in reverse) as the rear axle? In other words, I am assuming the oil goes under the ring gear and under the bottom of the pinion gear, but is there enough that carries over to splash consistently on the upper part of the axle cover?

I searched for a front axle YT video that had a clear cover, but could not find one.

Thanks in advance for any insight.

Note: these photos are for representation purposes only (these not my axles, though I do have a high pinion in the front and low pinion in the rear as shown).

Taking into account the ring gear rotation direction of the rear axle, the arrow on the bottom photo is typically the path the oil takes from the bottom of the housing and over the top of the ring gear. The temperature sensor is located in the axle cover about where the end of the red arrow ends and the temperature reading is steady while the axle is in motion.

The front axle is where I am scratching my head a little. Part of the problem is there is a front axle disconnect which prevents the ring gear and driveshaft from spinning while in 4x2 mode. I have not been able to get out and into 4x4 mode for any length of time since C19 hit. The few times that I have been in 4x4, the temperature gauge seems to read, but I want to be sure that where I have the sensor located (same place as the rear) is optimum.

My question is this—does the oil in the front axle follow the same path (but in reverse) as the rear axle? In other words, I am assuming the oil goes under the ring gear and under the bottom of the pinion gear, but is there enough that carries over to splash consistently on the upper part of the axle cover?

I searched for a front axle YT video that had a clear cover, but could not find one.

Thanks in advance for any insight.