I dont know how wet the Noxudol stays when sprayed in cavities.

@Trav do you have expertise on how hard it sets up after days/months/years?

Ive sprayed some cosmoline types of material in doors, tried heavy and light, and it all will set up hard, and can have cracks that would invite water. While I can appreciate the staying power of something like Cosmoline when sprayed on a few mils thick on exposed surfaces, it doesnt seem ideal to build. I had to top it with woolwax so that I was sure that there was not a place for water to sit and stand. The woolwax when not exposed to water and spray has excellent staying power and doesnt evaporate or disappear. Ive had it on some bolts on my Accord for many years in the door jambs, and it still is there.

I've been using Noxudol for 4 years now. I have the luxury of a well equipped shop, a few cavity guns and quite a few wands/nozzles etc. for application. We live in Northern Ontario where salt and sand is a daily occurrence in winter with temps hitting -35C. Rust is a big deal here.

You can read a rather exhaustive discussion at the samba I fired up a few yrs ago:

https://www.thesamba.com/vw/forum/archive/index.php/o-t--t-606491--.html

1. Rustcheck, Krown and Fluid Film will wash off exposed chassis parts in just a few hours of driving in heavy rain. On interior panels they fare better but really should be applied every year. This fellow’s real world tests and video are spot on :

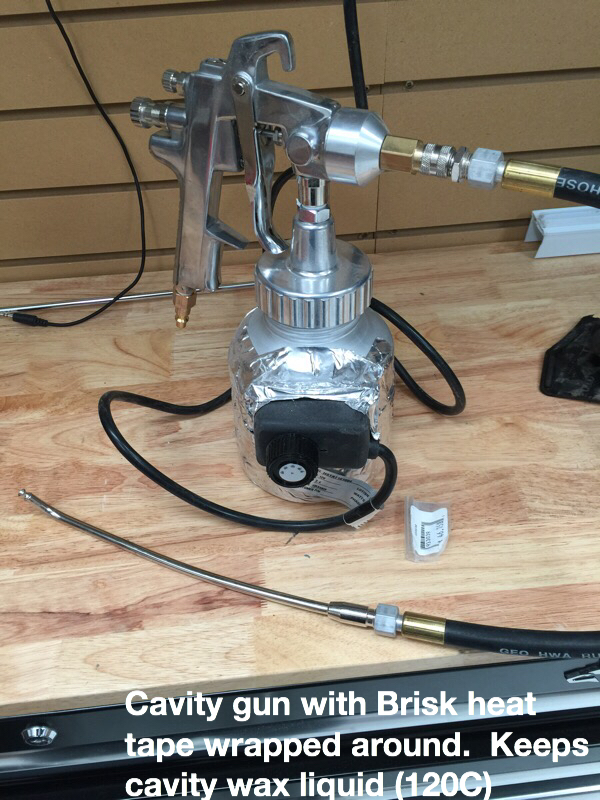

2. Mike Sanders grease is awesome as a cavity chassis wax but needs to applied at 90-100C. I have a five gallon pail, and heat tape wrapped gun to apply it. It is a major PITA to apply and it's viscosity makes seam creep (which you want) over time unlikely unless the body gets quite hot.

3.

Noxudol 700 won a three year test on body panels done by Classic Car Magazine in the UK. Google it. I did research on the product including a patent review and MSDS data. Both Noxudol 300 (black, heavier wax for exposed chassis) and Noxudol 700 (amber color, for interior or proetected panels) have active ingredients to react with and slow/stop rust. I suspect that is why Honda, Toyota and Isuzu (others?) have all specified these products for use in their recall programs. It is easy to apply and the 300/700 are solvent free.

I used the 300/700 on our 2014 Highlander during the summer of 2018 and can confirm that it has not washed off after many pressure washes..and can support the manufacturers suggestion of quick yearly touch ups vs full reapplication. I can also see surface rust under the amber 700 wax is slowly turning black, which makes sense given the active anti-rust chemicals they incorporate. Initial costs are more, but factor in the savings in subsequent years. The Highlander has required 1-2 liters of 300 over the four years for touch ups...that's it.

Honda spec’d Noxudol 300 and 700 for a frame rust recall.

https://static.nhtsa.gov/odi/rcl/2010/RCRIT-10V436-1234.pdf

Toyota also spec’d Noxudol 700 and in some cases 300 on multiple truck frame rust related recalls:

https://static.nhtsa.gov/odi/rcl/2009/RCRIT-09V444-6633.pdf

I paid full pop for these products and sadly get nothing from Noxudol, however it is my current number #1 recommendation.

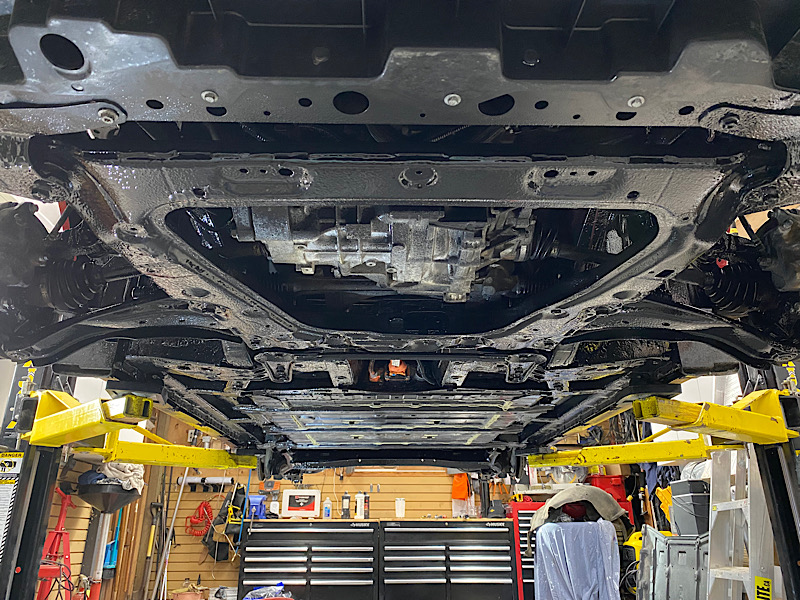

Finally, I did a full treatment on our 2018 LEAF, detailed here with quite a few pics:

https://mynissanleaf.com/viewtopic.php?t=32082

The 300 is sprayed on exposed bits, and the 700 is used inside frame channels, doors, etc. I left the 2018 LEAF EV up on the hoist for about 4-5 days as this is what it took for the 300 to "set" up to a waxy consistency vs wet/sticky when you first apply it. You'd likely want to avoid rain for a week or so after application. I took the time to remove the 5 aero panels, fender liners, rear lights etc. to do the job right.

The 300, right after application:

This is some information on Noxudol from an older post on the Samba where a few of use were having the rust chat:

A bit of research on the product (Noxudol 700) yields this:

http://www.google.com/patents/WO2011120646A1?cl=en

| Quote: |

| According to one embodiment, a composition containing sulfonic acids, petroleum, overbased calcium salts in an amount of 10 to 30% by weight; fatty acids, tall-oil, polymers with isophthalic acid, pentaerythritol and tall-oil in an amount of 10 to 20% by weight; paraffin waxes and hydrocarbon waxes in an amount of less than 10%; base oil, distillates (petroleum), solvent- refined heavy paraffinic materials in an amount of 40 to 60% by weight, each percentage being based on the total weight of the wax component, may be used. This material is available as the commercial product Noxudol 700 from Auson AB, Kungsbacka, Sweden. This material is of waxy appearance and includes a liquid paraffin component. |

A bit more research:

Sulphonic acids - rust cleaner

overbased calcium salts - oil additive to prevent rust

pentaerythritol - referenced in several corrosion inhibition papers.

polymers with isophthalic acid - referenced in corrosion resistance material

tall oils - used as a base for corrosion inhibitor products

It would appear that along with solvated paraffin wax, there are actually a few active ingredients that react with rust. These additives along with the persistence of the product is likely why Toyota, Isuzu and Honda have all spec'd these products for recall/warranty issues related to rust.

Sorry for the long post but I've pulled from some of my previous posts to provide a pretty good overview of the product, and why you might want to use it.