a. Formulations do indeed change, sometimes overnight. The data is dated.

b. Ah, now we get to what I believe is your thesis. How did you determine that Redline is trading wear protection for shift quality? How did that Mu(v) chart lead you to the conclusions you have made?

c. Shifting depends highly on the design vs horsepower being shifted and the leveraging component of the shift forces on the synchronizer.

d. How did operational parameters and transmission design affect the oil results? Were oil analysis done in each case to show some correlation, or was it that assumptions were being made without any proof?

e. What about the MTF chemistry that led you to this conclusion? What could a VOA possibly reveal?

f. What do you mean? What trends?

g. All oils decompose over time, hence the Service Intervals. The first thing that happens is that mechanical shear tends to thin the oil to a lower viscosity. Then, prolonged exposure to heat conducted from the engine eventually results in oxidative thickening.

a) - I agree

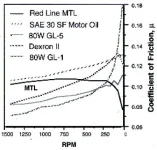

b) - this is a snippet of what I said.... "Redline would appear to have a formulation that really concentrates on synchronizer performance...." and what I mean, here, is that their marketing effort appears to play this up. The Mu(v) chart I attached only is in reference to their claim, i.e. the focus they appear to have on shift-feel... and I do not cite this attachment in reference to wear protection. The technical papers they put forward claim superior synchronizer behaviour with their formulation. Now,

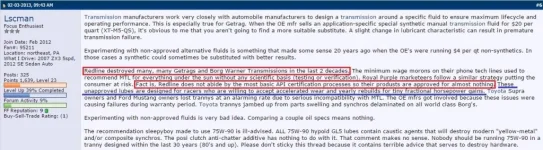

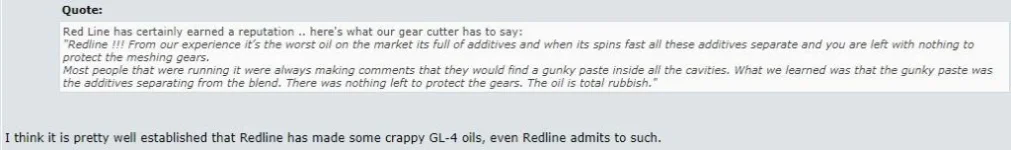

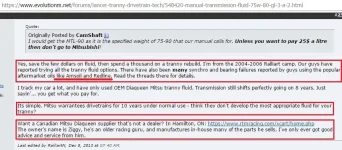

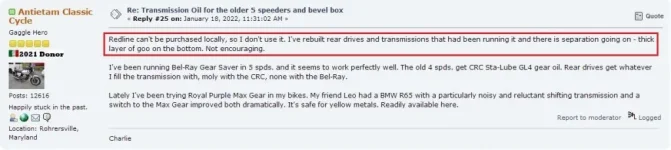

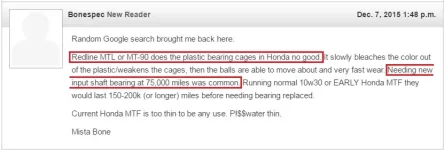

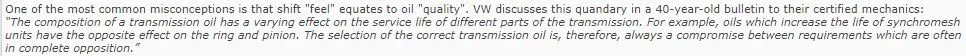

other than that the VW contention that synchronizer performance optimization goes in opposite directions from balance of transmission/transmission component longevity optimization (I am guessing, here, that VW principally refers to viscosity), the only thing I point to are the attachments I provide above suggesting (some rather strongly) that Redline MTL does not provide optimal longevity of the gear tooth surfaces, the rolling element bearings, or for that matter the composite (glass-filled nylon?) rolling element cages (in the case of the Honda transaxle comment). Are these "wear" comments due to lower viscosities that Redline

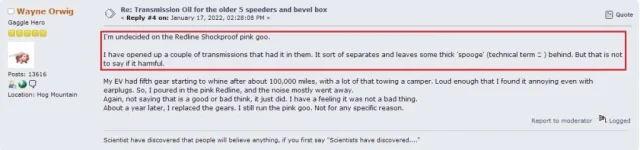

may try to "plumb", in deference to shift feel? I do know that AW additives, I believe, counter lower viscosity lubricants' tendencies to have heightened wear... but I do not have the knowledge to view the VOA's for Redline MTL to conclude that their formulation is- or is not optimal for component durability for these components. I do, however, see in some of the attachments that at least two parties have noted sludge, or fluid component drop-out into sumps and onto ledges. Seems to me that one can conclude that if something drops out of suspension - something that when the lubricant is

new (and properly in suspension) adds-to the performance of the fluid - well, that is likely not good!

c) your comment that "Shifting depends highly on the design vs horsepower being shifted and the leveraging component of the shift forces on the synchronizer".... I am not sure that HP comes-in to the picture, or at least the power that the transmission/transaxle is transmitting. The shift does not occur under power, but during a break in the application of the power (actually, the torque, not the power). A high torque-rated transmission has heavier components... and there is more inertia in said heavier components... but then presumably the cone-clutches are commensurately more-HD, bigger. What I said is that generally, lower viscosities of lubricant generally appear to make-for smoother-operating synchronizers.

d) your comment: "How did operational parameters and transmission design affect the oil results? Were oil analysis done in each case to show some correlation, or was it that assumptions were being made without any proof?" and then my "d)" I quote: d. What I seem to have found, when I searched for empirical behaviour, wear-evidence, physical sump- and ledge build-up of deposits - was presented in earlier posts. I don't know if this behaviour is that common, or indeed, whether it continues to occur to this day?

I offer only empirical information per the attachments, and it is not correlated to specific design parameters, and directly related UOA's. All I can see from those few attachments is that the posters seemed ardent in their dislike for the product (at least, at the time they posted the comments) - and at least one of the posters seems to have been pretty scientific in his/her approach of determining wear (in the Hewland transaxles he was dealing with). I would agree, those are dog-boxes, not synchro boxes... and they would have needed EP formulations for the R&P...but they certainly did wear (according to the poster) in areas other than the R&P (like gear faces).

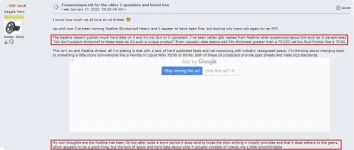

I think I've covered-off the rest of the comments.... but all I am saying is that I appear to have uncovered some negatives.... that might have some merit and I have to restate that:

-if Redline MTL has some brilliant chemistry that makes for excellent feeling shifts - that's great.... but is there any anecdotal evidence out there that the effect is of limited duration? Short-lived? And is there any info out there that suggests that Redline MTL lubricants shear in service pretty early-on? and

-I am all-in for Redline MTL if indeed it can be shown to be as protective as the more typical OEM-fitted lubricants (which notably are not Redline MTL). Otherwise I am willing to nurse my manual transmissions to full operating temp in deference to gaining full protective performance of the lubricant for the long-haul (because to some extent shift-feel when cold goes counter to full operating temp gear and bearing longevity when speaking of

viscosities, and allowing that AW formulations affect and modify this general rule).

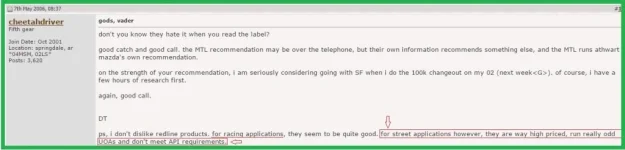

Oh, I found an old (2006) snip from Ferrari Life that is strange...