Originally Posted By: doitmyself

I'm curious how you are going to address the bottom corners?

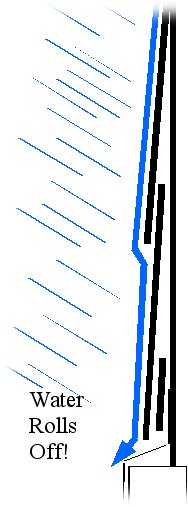

Aluminum and vinyl siding expand and contract quite a bit. Flashing/trim is supposed to be designed and installed so that it diverts water without caulk.

What are you planning to do with the J Channel at the bottom corners to keep water that is running down the J Channel from leaking behind the siding below....and then who knows where.

Also, I would have that unit tilting down 2% or more so the large top area will drain away from the house naturally.

The unit has about 1/2" slope per the instructions.

The old unit had that grey caulk around it as the only space filler and it was perfect and bone dry back there. If I just knew what that stuff was and how to apply, I'd likely be done.

I'm curious how you are going to address the bottom corners?

Aluminum and vinyl siding expand and contract quite a bit. Flashing/trim is supposed to be designed and installed so that it diverts water without caulk.

What are you planning to do with the J Channel at the bottom corners to keep water that is running down the J Channel from leaking behind the siding below....and then who knows where.

Also, I would have that unit tilting down 2% or more so the large top area will drain away from the house naturally.

The unit has about 1/2" slope per the instructions.

The old unit had that grey caulk around it as the only space filler and it was perfect and bone dry back there. If I just knew what that stuff was and how to apply, I'd likely be done.