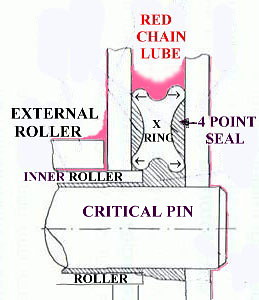

^^^ This^^^ ...was the intent with my words.What we are lubing are external roller and between the roller and the

sprockets (red area in my drawing)... we are not lubing the X rings

nor behind the X rings so any oil applied in that effort is a waste

and will only fling off...

- Home

- Forums

- Motorcycles, Boating, Small Engine, Aviation, Powe

- Motorcycles and Motorcycle Lubrication

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

55 Chain Lubes Tested

- Thread starter BBDartCA

- Start date

In the cross section diagram, the red lube under the external roller (which is really the only "roller") is not sealed in any way, and can freely rotate (roll). The only way to correctly lube it is to use a lube that will wick into the inside of the roller from the unsealed ends of the roller.

What's labelled as "inner roller" on the cross section is not really a roller because it doesn't freely move. It's a fixed tube that is firmly pressed into the inner side links that the "critical pin" that's pressed into the outside side links rotates in.

What's labelled as "inner roller" on the cross section is not really a roller because it doesn't freely move. It's a fixed tube that is firmly pressed into the inner side links that the "critical pin" that's pressed into the outside side links rotates in.

Last edited:

It looks like you've got a link that's binding, just coming off the countershaft sprocket. About time for a new chain.

Good eye! Absolutely a link that's binding, kinda looks like the link just behind that one is slightly binding too. Not real bad, but its time has come to retire.

I recommend Motul Chain Paste... squeeze the white grease from the

tube and load the brush... Hold the loaded brush to the inside of the

chain rollers to transfer the white grease... After a couple of spins

of the chain it's lubed like from the Factory... Motul Chain Paste

clings with no flings...

Your chain looks just a bit lose... Some guys at the track run their chain a bit on the lose side so the power comes on a little bit smoother off the turns. Downs side, more sprocket/chain wear. Tighter chain with high HP can't get on the throttle as early and the front wheel seems to not want to stay down off the slower turns.

I had a couple Hona Dreams C77 model and their drive chain was enclosed. Gear oil in a pump can with some STP worked great.

Your chain looks just a bit lose... Some guys at the track run their chain a bit on the lose side so the power comes on a little bit smoother off the turns. Downs side, more sprocket/chain wear. Tighter chain with high HP can't get on the throttle as early and the front wheel seems to not want to stay down off the slower turns.

I don't know about the racing stuff, but a looser chain definitely does not cause more wear. Quite the opposite in fact.

It looks like you've got a link that's binding, just coming off the countershaft sprocket. About time for a new chain.

Good eye! Absolutely a link that's binding, kinda looks like the link just behind that one is slightly binding too. Not real bad, but its time has come to retire.

Good eye indeed, but that chain was only a year or two old and it was stiff right from the beginning and had few links like that, but they moved no problem. It doesn't matter though because I sold years ago.

Last edited:

That is correct in my experience. A slightly loose chain within reason is much easier on driveline components than one that is slightly tight. To that end, I set mine at the loose end of spec or a bit looser. Don't know how much more life I could get out of a chain than well over 30,000 miles on a EK 530 ZVX chain on 150 hp/87 lb-ft torque machine.I don't know about the racing stuff, but a looser chain definitely does not cause more wear. Quite the opposite in fact.

Chain tension spec's are all over the place depending what manual you look at or who you ask for feed back, or the method of how you perform your tension checks . Most do not actually check it properly. Tech inspection at the track fails more bikes for a tight chain than a loose chain than any other failures period.

Depending on the angle and arc of your rear swing arm and the amount of travel will make a large factor on the amount of slack your chain will require. Most riders will adjust on a center stand if they have one, and as you torque down the rear axle the chain tightens as you torque the rear axle.

Some manuals suggest 20 to 30mm or .78 to 1.18 but if you adjust to that spec on the stand with the axle torqued it will be off because you should actually measure it when your sitting on the bike and not on the center stand. It really takes two people to measure properly if that is the measurement your looking for. Some of the track riders are running 1.5 to 1.75 at a minimum, even 2.0 inches because when the chain heats up it tightens up and street riders don't get their chains hot enough. Chain stretch is a different category and must be dealt with on a constant basis.

Now if you want to be a stunt rider and you want your front end to snap right up so you can show off and maybe kill your self or some innocent person or injure yourself for life, try .50 inch with 160 HP at the tire and snap the throttle at 100+ 120+ in 3rd and front wheel stands right up as high as you want it. That is hard on your chain.

If you watch the stunt movie Urban Assault, I'm cropped out of alot of it...lol, Some or a lot of the canyon parts are Ortega HWY, used to be a weekend ride for me or the back side of Palomar.

Depending on the angle and arc of your rear swing arm and the amount of travel will make a large factor on the amount of slack your chain will require. Most riders will adjust on a center stand if they have one, and as you torque down the rear axle the chain tightens as you torque the rear axle.

Some manuals suggest 20 to 30mm or .78 to 1.18 but if you adjust to that spec on the stand with the axle torqued it will be off because you should actually measure it when your sitting on the bike and not on the center stand. It really takes two people to measure properly if that is the measurement your looking for. Some of the track riders are running 1.5 to 1.75 at a minimum, even 2.0 inches because when the chain heats up it tightens up and street riders don't get their chains hot enough. Chain stretch is a different category and must be dealt with on a constant basis.

Now if you want to be a stunt rider and you want your front end to snap right up so you can show off and maybe kill your self or some innocent person or injure yourself for life, try .50 inch with 160 HP at the tire and snap the throttle at 100+ 120+ in 3rd and front wheel stands right up as high as you want it. That is hard on your chain.

If you watch the stunt movie Urban Assault, I'm cropped out of alot of it...lol, Some or a lot of the canyon parts are Ortega HWY, used to be a weekend ride for me or the back side of Palomar.

That is correct in my experience. A slightly loose chain within reason is much easier on driveline components than one that is slightly tight. To that end, I set mine at the loose end of spec or a bit looser. Don't know how much more life I could get out of a chain than well over 30,000 miles on a EK 530 ZVX chain on 150 hp/87 lb-ft torque machine.

I would go through about 5 or 6 chains in 30,000 miles and 3 bikes or more. I usually did not make it more than 5K before I had to overhaul the trans and usually just put in new shifting forks, but I've cracked my fair share of gears too.

If the engineers who supply info that goes into the owner's manual or service manual did it right, they should be taking all of that into consideration. So if they say adjust the chain to 25 mm of slack for instance specifically on the center stand, then it should be right for any riding conditions and not be too tight when the suspension compresses to the point were the chain is at the tightest point.Chain tension spec's are all over the place depending what manual you look at or who you ask for feed back, or the method of how you perform your tension checks . Most do not actually check it properly. Tech inspection at the track fails more bikes for a tight chain than a loose chain than any other failures period.

Depending on the angle and arc of your rear swing arm and the amount of travel will make a large factor on the amount of slack your chain will require. Most riders will adjust on a center stand if they have one, and as you torque down the rear axle the chain tightens as you torque the rear axle.

Some manuals suggest 20 to 30mm or .78 to 1.18 but if you adjust to that spec on the stand with the axle torqued it will be off because you should actually measure it when your sitting on the bike and not on the center stand. It really takes two people to measure properly if that is the measurement your looking for. Some of the track riders are running 1.5 to 1.75 at a minimum, even 2.0 inches because when the chain heats up it tightens up and street riders don't get their chains hot enough. Chain stretch is a different category and must be dealt with on a constant basis.

And of course, always check the chain slack again after everything is tightened back up. If it changed, then do it again until it comes out right ... been there, done that.

The engineers don't always take into consideration the very few percent that actually beat the living daylights out of their bikes on the track, and chains can and do sometimes tighten up when they get really hot, which they do. I would not run my chain at 30mm or 1.18 unless I putted around town and to me there is no sense in that, that's where the real danger is, trash trucks, busses, and taxi cab's, no thanks'.

95% or more of sport bike owners ever come close to using the potential of a sport bike, those that think they can do it in the canyon or the street just don't have a clue because they have not put their wheels on the track. Just like the suspension is set up for that 95%. The engineers have to tailor a bike for one size fits all, just as I mentioned that some guys like a chain more lose due to the fact that it is smoother getting on the throttle off the turns. It's a preference and most riders, that 95% would never know the difference.

Have you ever dropped the forks .50 to .70 in the triple clamps and reset the sag? Did that make an enormous difference in how the bike turned in? It just flop's right over effortlessly with the right tire combo. The engineers did not do that for you. I realize we are not in the oil section, but how many ignore what the engineers recommend for oil weight= Thick/Thin... Engineers=Guidelines

95% or more of sport bike owners ever come close to using the potential of a sport bike, those that think they can do it in the canyon or the street just don't have a clue because they have not put their wheels on the track. Just like the suspension is set up for that 95%. The engineers have to tailor a bike for one size fits all, just as I mentioned that some guys like a chain more lose due to the fact that it is smoother getting on the throttle off the turns. It's a preference and most riders, that 95% would never know the difference.

Have you ever dropped the forks .50 to .70 in the triple clamps and reset the sag? Did that make an enormous difference in how the bike turned in? It just flop's right over effortlessly with the right tire combo. The engineers did not do that for you. I realize we are not in the oil section, but how many ignore what the engineers recommend for oil weight= Thick/Thin... Engineers=Guidelines

Cycle engineers aren't setting up cycles coming out of the factory or writing OMs and Service Manuals for track racing application, they are more focused on normal street type application.Have you ever dropped the forks .50 to .70 in the triple clamps and reset the sag? Did that make an enormous difference in how the bike turned in? It just flop's right over effortlessly with the right tire combo. The engineers did not do that for you. I realize we are not in the oil section, but how many ignore what the engineers recommend for oil weight= Thick/Thin... Engineers=Guidelines

At lease cycle manufacturing engineers are not driven by CAFE and specify oil viscosity more correctly than US auto makers do.

I've used a blue paper shop towel dampened with kerosene for years to wipe my chain down. Don't need to wipe it down much anymore because the Honda HP4 Moly lube I mentioned earlier this thread just doesn't make much mess. Nor does it attract much dirt for the most part.

With respect to over 30,000 miles on a chain, admittedly I ride spirited on the street here and there however I am not a heavy on/off throttle guy. I work to be smooth and that lessens the load on the chain as a byproduct. Keep an even hand on the throttle and keep the drivetrain "loaded" as opposed to the on/off throttle which it puts more sudden load on the chain.

With respect to over 30,000 miles on a chain, admittedly I ride spirited on the street here and there however I am not a heavy on/off throttle guy. I work to be smooth and that lessens the load on the chain as a byproduct. Keep an even hand on the throttle and keep the drivetrain "loaded" as opposed to the on/off throttle which it puts more sudden load on the chain.

After my grunge brush, I use mineral oil and a paint brush to remove remaining dirt. After drying with a terry-cloth towel I paint on a layer of bar/chain oil. Let sit for a few minutes and towel wipe the excess. Seems to work quite well.

Cycle engineers aren't setting up cycles coming out of the factory or writing OMs and Service Manuals for track racing application, they are more focused on normal street type application.

At lease cycle manufacturing engineers are not driven by CAFE and specify oil viscosity more correctly than US auto makers do.

I could not agree with you more! I'm merely stating one size does not fit all. Japanese sport bikes, 600's, 750's, 1000's are engineered toward a 160 pound rider that rides around town and limited performance riding. That's not B.S. Its a fact. Aside from that, you and I both know most riders of these Sport bikes can barley ride them to 50% of their capability and that is being generous, even if they have done a track day or 2. Doing a track day for a Virgin is quite the eye opener to say the least. It will make the more hard core weekend canyon riders realize how delicate the Balance of their body position and lean angle is of paramount. It will also make them realize how slow they are and how long it takes to learn the lines around a track. Along that curve of learning the lines around the track will give many of riders insight of the need for adjustments and "Hopefully" someone with some experience will be there to help guide them. I had help, I absorbed every bit I could and clocked laps behind every rider in the pro class I could keep up with and learn from, cheers.

I cleaned my chain after riding while it was warm with WD-40 sprayed on blue shop towels, my chain was never very dirty since I cleaned it every time I rode my bike. Do not spray WD-40 directly on your chain Please.

Every few times I cleaned it, I would use Bel-Ray Super Clean Chain Lube at a minimal level. You want the chain to be warm when you apply and not apply too much because it will fling off and will end up on your rear tire and rear brake rotor exactly where you do not want it! Remember, your only lubing the roller on the links because you should have a sealed Oring chain. Harsh cleaners can and will beak down the Orings over time. I had tried others like the wax, but with the wax you can see the funky looking whitish wax build up on your chain.

I would also suggest you use some news paper to block over spray of any lube you chose to use due to the over spray that will end up on your swing arm and other parts, Tire, rear rotor.

Clean wheels same way, blue shop towel, spray WD-40 on shop towel only and wipe the dirt or in my case, rubber off the wheel and be careful not to touch your rotors front or rear.

Every few times I cleaned it, I would use Bel-Ray Super Clean Chain Lube at a minimal level. You want the chain to be warm when you apply and not apply too much because it will fling off and will end up on your rear tire and rear brake rotor exactly where you do not want it! Remember, your only lubing the roller on the links because you should have a sealed Oring chain. Harsh cleaners can and will beak down the Orings over time. I had tried others like the wax, but with the wax you can see the funky looking whitish wax build up on your chain.

I would also suggest you use some news paper to block over spray of any lube you chose to use due to the over spray that will end up on your swing arm and other parts, Tire, rear rotor.

Clean wheels same way, blue shop towel, spray WD-40 on shop towel only and wipe the dirt or in my case, rubber off the wheel and be careful not to touch your rotors front or rear.

I use cereal box card board and lube the chain on the inside of the botton chain run (fully exposed area of the chain on my bike), works very well. Can cut the cereal box to make a shield that blocks any over spray. Can do it all (clean and lube) with the bike on the side stand. Just have to roll the bike 3 or 4 times to do the whole chain length.I would also suggest you use some news paper to block over spray of any lube you chose to use due to the over spray that will end up on your swing arm and other parts, Tire, rear rotor.

Last edited:

Similar threads

- Replies

- 28

- Views

- 4K

- Replies

- 9

- Views

- 1K

- Replies

- 16

- Views

- 1K