When I researched (adnauseum) torque wrench brands 12 years ago before making my workplace selections, if one searches hard enough, you can find a negative post or two about any brand. I remember one fellow in avionics that claimed Snap On torque wrenches seemed to have the highest incidence of being out of calibration straight from the factory. Protos were subject to this or that, Sturdevant Richmont bla,bla,bla. You would also find numerous references of Harbor Freight torque wrenches testing as good as any major brand.

A person has to trust that the major companies whose sole endeavor is manufacturing torque wrenches is going to get it right most of the time. More important is that a person educates themselves about the torque process, the limitations of torque wrenches, and learn the proper way to use and maintain them.

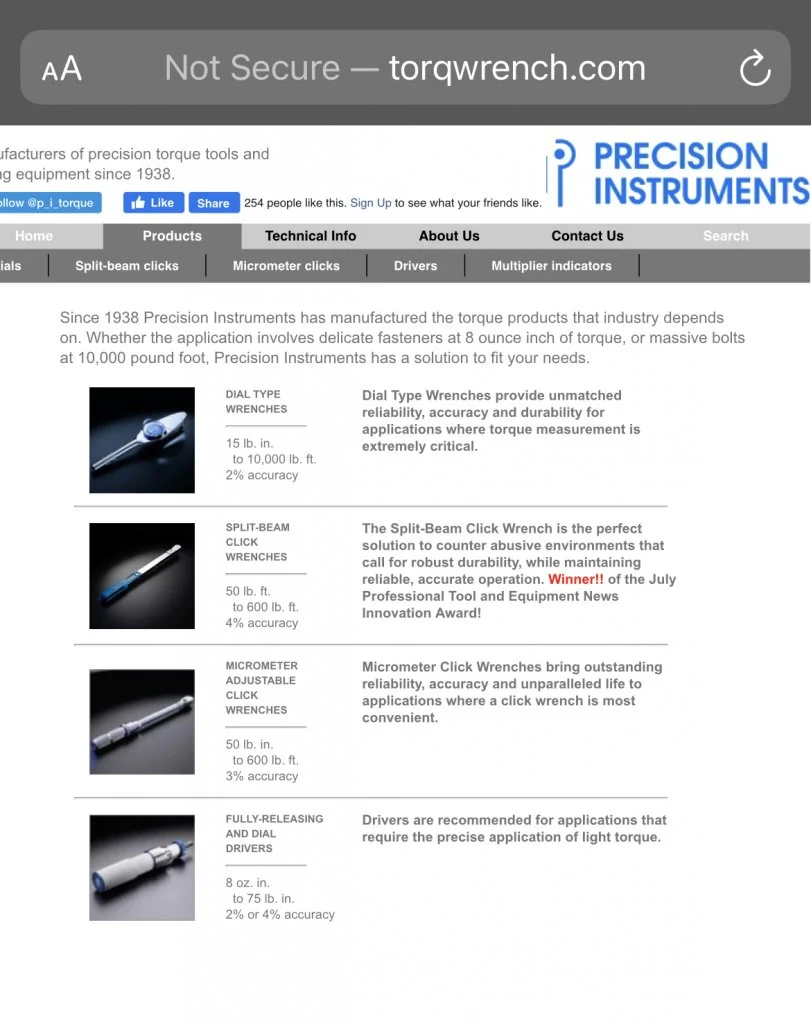

It's hard to get the perfect overlap of ranges, even with three wrenches. I have the Snap On Tech Angle 50-250 in. lb. (4 - 20 ft. lb.), PI 3/8 (20-100 ft. lb.) and PI 1/2 in (50-250). I'm weak in the the 20 ft. lb. range. The Critic is weak in the 50 ft. lb. range with his 3 wrenches.

My Snap On is nice for delicate fasteners because you can read the advancing torque like a dial wrench. I don't do torque to yield, heads, etc..