JTK

$100 Site Donor 2025

For me sil-glyde always seemed to dry out and get sticky on caliper pins. I switched to a jar of 3M silicone grease a year or two ago.

I noticed that the oil in anti seize dries out, but a thin coat of it remains and it doesn’t attract dirt. Caliper pin grease attracts dirt before it dries out and becomes crusty/flaky.Copper anti-seize also dries out when applied on pads ears. At least that has been my experience with the 3M one.

Very few products "last" when exposed to the elements if you only apply a thin coat.

Tesla maintenance service includes cleaning and lubing brake components in colder regions.Copper anti-seize also dries out when applied on pads ears. At least that has been my experience with the 3M one.

Very few products "last" when exposed to the elements if you only apply a thin coat.

This makes perfect sense for Tesla since it uses regen braking a lot, so pads don't do a lot of work and therefore don't move in the bracket, so they can rust in quite easily.Tesla maintenance service includes cleaning and lubing brake components in colder regions.

The other item is cabin air filter.

You might be surprised. It is all too common to replace pads that have grossly uneven wear between the inboard and outboard pads.In mild climates like CA, you probably don't need to do anything special beside cleaning the contact points.

Lubing the contact points tends to make the situation worse unless it is the ATE-style calipers.You might be surprised. It is all too common to replace pads that have grossly uneven wear between the inboard and outboard pads.

Prepare the bracket and lube those bad boys!

How much better is the Honda M77 in that regard?Copper anti-seize also dries out when applied on pads ears. At least that has been my experience with the 3M one.

Very few products "last" when exposed to the elements if you only apply a thin coat.

M77 definitely stays on a bit better IMO because the solid contents is higher.How much better is the Honda M77 in that regard?

(I’m assuming that is what you would use)

I’d think that the Cu paste also has a bit of Mo/Graphite, but not to the same levels. And who knows the difference in carrier oil...

I don't wash my cars and M77 isn't there after 2 years. Just a hint after one. Our cars tend to get a lot of miles though.M77 definitely stays on a bit better IMO because the solid contents is higher.

But if you apply both products lightly (like a film), there won't be much remaining after 5 years of wheel cleaning with stronger cleaners.

I have never tried copper anti seize on brake parts. In my area it’s much more expensive than the aluminum but you also get a greater amount so for every brake job my shop does we’d probably burn through the stuff. Wonder if aluminum based would do the same? I usually use the aluminum for drum brake contact points in the rare times we see drum brakes. I know the purple Permatex stuff works pretty good on the metal to metal but not sure how long it lasts.

https://www.ate-na.com/products/ate-plastilube-brake-lubricant/

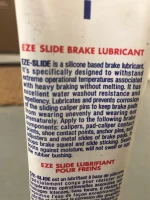

this is what i use. i presume this is the factory slider grease on ate calipers