Hi Everyone,

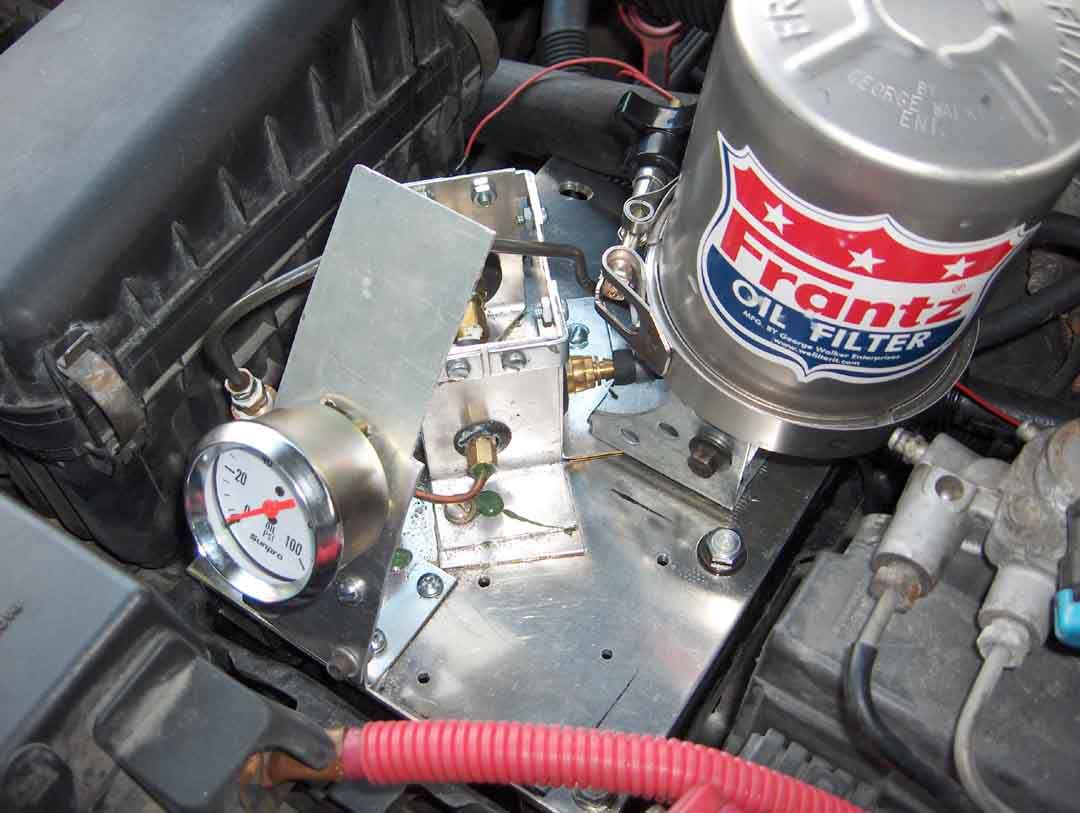

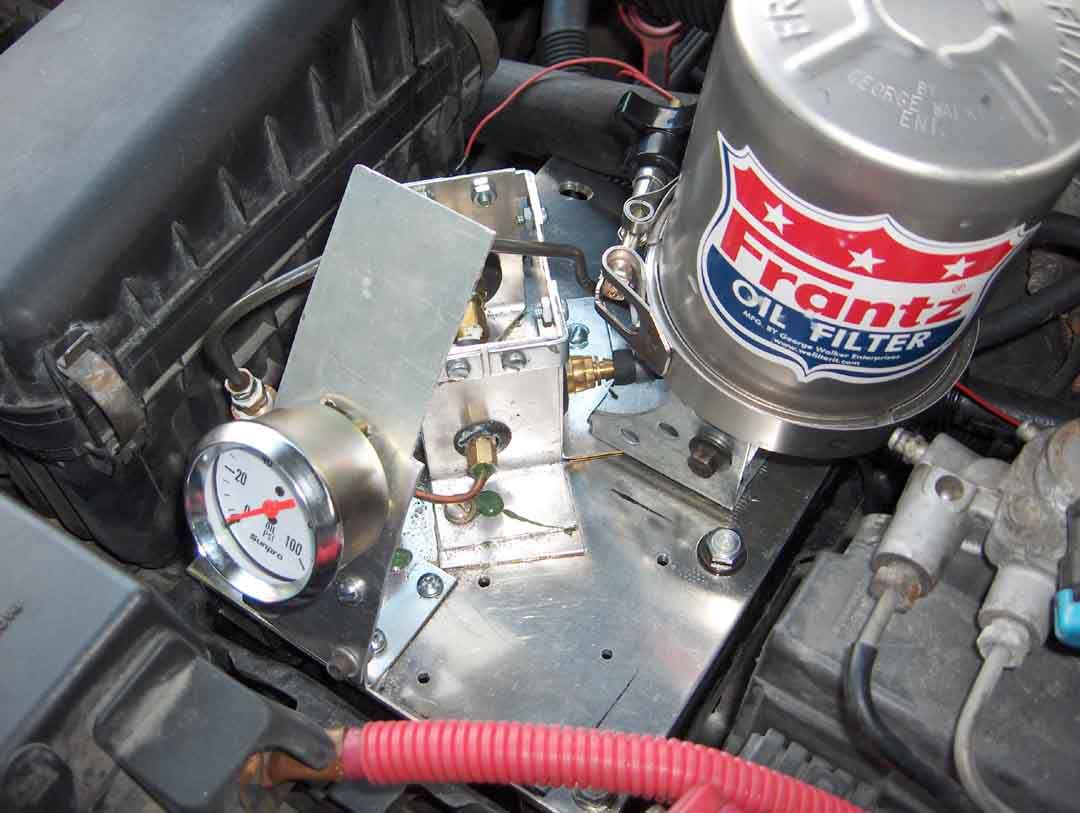

This is an installation of a Frantz bypass filter on a Saturn SL2 1995. Battery was moved into the trunk. All kits/ parts were bought using Ebay and local hardware stores

Here's pictures of three different vantage points:

A picture of the oil pressure meter while ball valve is closed:

"" after the ball valve is opened with new TP roll:

As you can see, I used a frame made of sheet metal. To keep the pipe fittings snug and without much vibration, I used rubber grommets. There is an Aluminum metal plate that everything sits on. This plate is supported and raised up 1" by two hollow metal bars that attach to the two longest sides. Liquid teflon was applied to all fittings. Everything is leak tight except for the fitting connecting the brake line & frantz's inlet. I found out that brake line is too rigid to use for connecting to the Frantz since the filter vibrates. The brake line causes that fitting to Start dripping and gets progressively worse. Very soon I will replace this with rubber hose. For now the ball valve is closed and no oil is flowing through the Frantz at this time.

This is an installation of a Frantz bypass filter on a Saturn SL2 1995. Battery was moved into the trunk. All kits/ parts were bought using Ebay and local hardware stores

Here's pictures of three different vantage points:

A picture of the oil pressure meter while ball valve is closed:

"" after the ball valve is opened with new TP roll:

As you can see, I used a frame made of sheet metal. To keep the pipe fittings snug and without much vibration, I used rubber grommets. There is an Aluminum metal plate that everything sits on. This plate is supported and raised up 1" by two hollow metal bars that attach to the two longest sides. Liquid teflon was applied to all fittings. Everything is leak tight except for the fitting connecting the brake line & frantz's inlet. I found out that brake line is too rigid to use for connecting to the Frantz since the filter vibrates. The brake line causes that fitting to Start dripping and gets progressively worse. Very soon I will replace this with rubber hose. For now the ball valve is closed and no oil is flowing through the Frantz at this time.