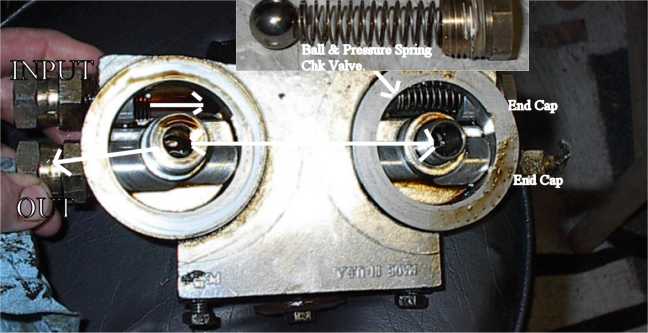

This is the picture of what I have, Trucku. The brass end is off, the spring is out and the ball bearing is out. The bearing goes in first, followed by the spring, then the end cap. Apparently it holds oil pressure going through this mount so that it goes first to the bypass and it gets a share of the pressure, and then it goes on to the full flow, as soon as the spring compresses under the oil pressure a bit, and then the full flow gets it's share. Goes through the full flow (small holes and out the center hole, back down the bracket and mixes with oil coming from the bypass filter and away they go back to the remote mount (pictured) that attaches to the spin-on oil filter space. Gary, please correct me if I'm wrong or I have this set up bass ackward or such

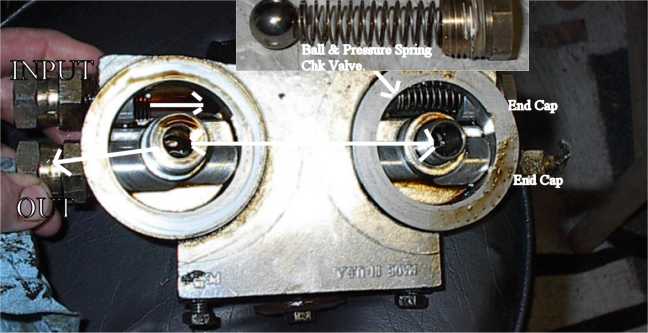

Second image is of the whole outfit with the brass plugs in and a better view of the mount for the oil spin-on adapter.

Unfortunately, I don't have room on either cars for this set up. So it sits in the shed. What I have enough room for is just a bypass filter element, which is why I have dwelt so long on the sandwich affair.

Really neat invention, using the spring and ball to help control oil flow. I would imagine it would even be able to be tweaked to some extent by the amount of spring tension, length, etc. on that spring either by shims or by different spring. You would need to use a pressure gage to determine the shift and what is acceptable using that method. For that matter, one with skills could drill and tap this mount and install a line for a pressure gage before and after the spring and get an idea of how much load is going through the filter, and could be an indication of when the filter 'ought' to be changed.

Vern