Originally Posted By: digitalSniperX1

Besides viscosity, what is it about oil that creates smooth shifting and dampens notchiness? In fact, two different and high quality oils with the same viscosity can feel very different. Any input would be appreciated. Thanks.

Ive enjoyed following this thread, been WAY to busy at work and havent been in here much. Anyway, like most, find the oil subject fascinating at times. Yet, when you read these posts, its why I suggest to people who ask, its best to listen to your owners manual, because chances are, believe it or not, the people who design your engine know a heck of a lot more about what oil to use in it and whos engines and transmissions have been tested over and over again, then anyone in these forums who may suggest otherwise.

But to answer your question...

as a general rule I think most people find more heavy viscosity improves shifting as most people notice shifting gets notchy over time in shared sumps when hot due to shear.

I honestly believe viscosity is the biggest factor.

When you state, two highly regarded oils of the same viscosity can feel different, again I would say, out of the two of the same viscosity, I would still bet the one with the higher viscosity will feel/shift better.

Here is why, two oils of the same viscosity, really may not be the same viscosity, they maybe rated at the same viscosity but in reality one 50 weight oil can have a viscosity that is 25% MORE THEN ANOTHER AND STILL BE A 50 WEIGHT OIL. So the more heavy 50 will shift better when hot.

Im not saying this is the only reason, I am saying it is reasonable reason for an answer to most of your question.

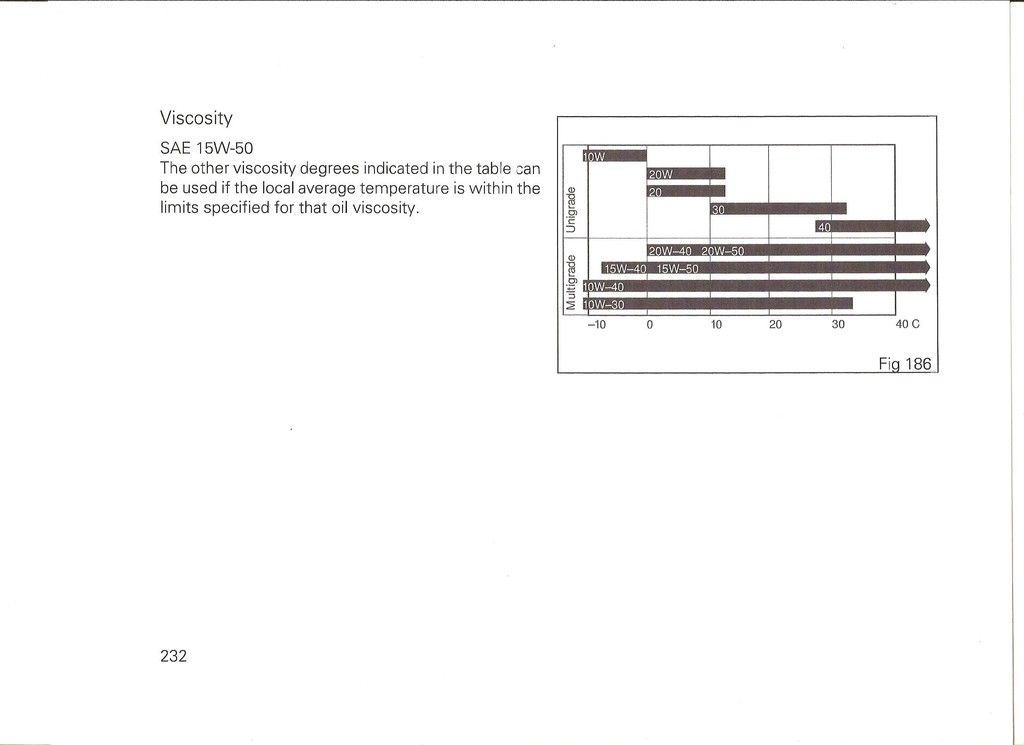

Here is the range for rated viscosities, 20,30,40,50 etc but just because it falls in the rated range, it is not the true "weight" for lack of better words.

The chart shows the viscosity of a 50 rated oil (or any really) can vary by as much as 25%, I am willing to bet, the more heavy 50s shift nicer then the lighter. Again, NOT THE ONLY REASON but a big factor.

Besides viscosity, what is it about oil that creates smooth shifting and dampens notchiness? In fact, two different and high quality oils with the same viscosity can feel very different. Any input would be appreciated. Thanks.

Ive enjoyed following this thread, been WAY to busy at work and havent been in here much. Anyway, like most, find the oil subject fascinating at times. Yet, when you read these posts, its why I suggest to people who ask, its best to listen to your owners manual, because chances are, believe it or not, the people who design your engine know a heck of a lot more about what oil to use in it and whos engines and transmissions have been tested over and over again, then anyone in these forums who may suggest otherwise.

But to answer your question...

as a general rule I think most people find more heavy viscosity improves shifting as most people notice shifting gets notchy over time in shared sumps when hot due to shear.

I honestly believe viscosity is the biggest factor.

When you state, two highly regarded oils of the same viscosity can feel different, again I would say, out of the two of the same viscosity, I would still bet the one with the higher viscosity will feel/shift better.

Here is why, two oils of the same viscosity, really may not be the same viscosity, they maybe rated at the same viscosity but in reality one 50 weight oil can have a viscosity that is 25% MORE THEN ANOTHER AND STILL BE A 50 WEIGHT OIL. So the more heavy 50 will shift better when hot.

Im not saying this is the only reason, I am saying it is reasonable reason for an answer to most of your question.

Here is the range for rated viscosities, 20,30,40,50 etc but just because it falls in the rated range, it is not the true "weight" for lack of better words.

The chart shows the viscosity of a 50 rated oil (or any really) can vary by as much as 25%, I am willing to bet, the more heavy 50s shift nicer then the lighter. Again, NOT THE ONLY REASON but a big factor.

Last edited: