- Joined

- Feb 17, 2022

- Messages

- 10

I have a Swedish 2-cycle gas powered jackhammer/rock drill (Pionjar 120) that species a 1:12 mix ratio. That seems excessive to me. I think that was probably an appropriate ratio with the oils available when it was made but I'm not sure that is still the case.

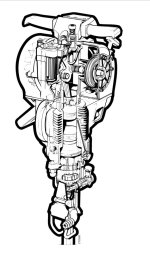

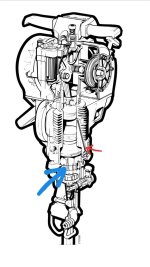

It is 185 cc, air cooled, cast iron cylinder, 2850 rpm engine with the cylinder down (crank is at the top). This is where it gets interesting. The combustion chamber is 2 opposing pistons, the lower is connected to the hammer mechanism (pic attached for the visual folks). There is no normal throttle (there is an adjustment that requires a screwdriver); the compression is really low until you push down on the hammer providing back pressure to the 2nd piston raising the compression. The engine runs rough and slow until this force is applied which acts as a sort of automatic throttling mechanism. The hammer mechanism is lubricated by oil left after combustion passing down into the lower parts of the mechanism (some seepage past the rings of the lower piston, some through a special port).

The oil specification is: the discontinued manufacturer's specific oil or "a recommended 2-stroke oil".

Considering the much better quality oils available today is it really necessary to run that much oil? It's going to be costly feeding this thing that much oil. I'm thinking it would be better to get a quality oil and run it at 1:20 or so instead. But I'm very overwhelmed with oil specifications and need a little guidance. Any thought or guidance that may help guide me? This thing isn't running at high rpms (and it's a low temp spark plug) but it will see continuous full-throttle use while deep hole drilling in rock. I want to keep it lubricated but not break the bank!

It is 185 cc, air cooled, cast iron cylinder, 2850 rpm engine with the cylinder down (crank is at the top). This is where it gets interesting. The combustion chamber is 2 opposing pistons, the lower is connected to the hammer mechanism (pic attached for the visual folks). There is no normal throttle (there is an adjustment that requires a screwdriver); the compression is really low until you push down on the hammer providing back pressure to the 2nd piston raising the compression. The engine runs rough and slow until this force is applied which acts as a sort of automatic throttling mechanism. The hammer mechanism is lubricated by oil left after combustion passing down into the lower parts of the mechanism (some seepage past the rings of the lower piston, some through a special port).

The oil specification is: the discontinued manufacturer's specific oil or "a recommended 2-stroke oil".

Considering the much better quality oils available today is it really necessary to run that much oil? It's going to be costly feeding this thing that much oil. I'm thinking it would be better to get a quality oil and run it at 1:20 or so instead. But I'm very overwhelmed with oil specifications and need a little guidance. Any thought or guidance that may help guide me? This thing isn't running at high rpms (and it's a low temp spark plug) but it will see continuous full-throttle use while deep hole drilling in rock. I want to keep it lubricated but not break the bank!