I'm sure the Tenifer finish is swell and all, but the newer finish isn't bad. The finish on my early Gen 4 G19 is as good as the day I brought it home and its been rode hard and put away wet. No rust, no wear, no problems. It's had some scratches that rubbed right out. Whatever it is they used, and it does look like a non-stick frying pan, works very well, from my experience.The absolute best finish Glock ever had, or ever will have, was the Austrian applied Tenifer finish. It had a nice sheen and color to it, good natural lubricity, was extremely hard, and it was virtually indestructible. Not to mention, you had to all but try to come up with a way to make a part rust that was treated with it.

Tenifer is somewhat similar to the Melonite process, but requires different chemicals and application procedures and temperatures. While many claim they are the same , they are not. Tenifer is superior in most every way.

The reason Glock changed the finish, was because the EPA has very stringent, costly requirements on the disposal of the chemicals used in Tenifer's application. Which makes it expensive to the point of becoming cost prohibitive to apply it here. It's not "banned" here as some have said. Just made to be very costly, because of government regulations regarding it's chemicals.

And it became cost prohibitive, along with creating logistical issues, for Glock to have the parts treated with Tenifer in Austria, (where the EPA has no authority, and where the process is very common), then shipped here for assembly into finished pistols at their New Smyrna, Georgia facility.

So Glock went to a type of Melonite finish similar to Springfield Armory's Melonite finish that they apply to their XD series of handguns. This is the finish that Glock uses today. It has a different color, (more of an ash grey), and has less sheen to it. While it can be deemed as satisfactory, many, including myself, believe it's not as durable, and more prone to rusting issues.

Simply put, Austrian manufactured, (Gen 1, 2, and 3), Tenifer treated Glocks have what many consider to be the best finish ever applied to a modern service pistol.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My 3rd Ever Glock

- Thread starter BlueOvalFitter

- Start date

Tenifer is not a finish but absorbed into the metal (it penetrates into the metal surface)...the black color finish is added on top of the Tenifer and has changed several times in the progression of GLOCK pistols...I don't believe GLOCKs have used Tenifer for some time but may use something similar...

It lightens the trigger pull to 3.5 lbs. it’s easy enough to install. Glocks aren’t complex.What is a Ghost 3.5 Connector and what does it do for a Glock trigger?

But I’m not a fan for a carry gun. Modifications of trigger function in a duty/carry gun are a potential liability.

For a target/range/competition gun, sure, the Ghost connector is popular. I don’t have one. I’ve got a complete Apex trigger for G19/17 but never bothered to put it in. They‘re nice, but I bought it to make my G17 more of a competition gun and I haven’t done a pistol competition in a while.

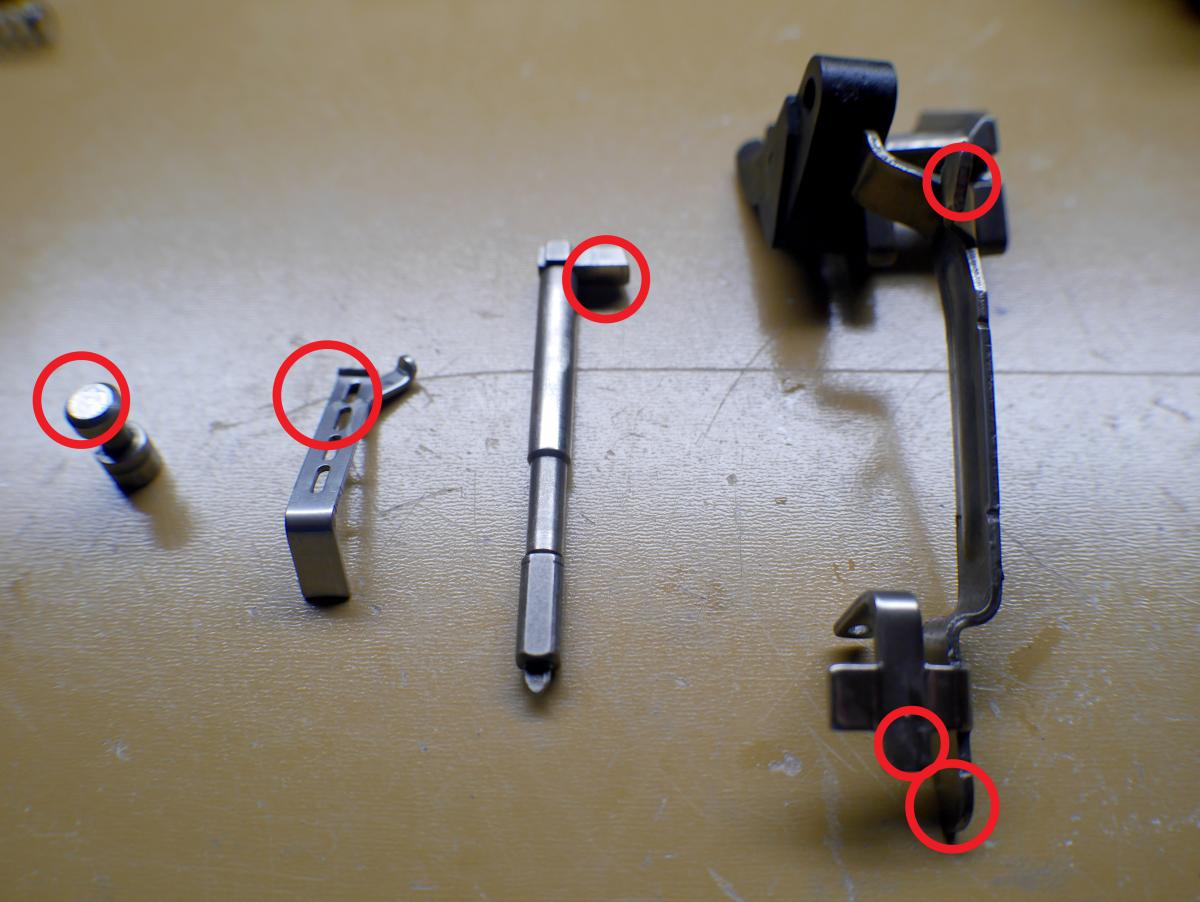

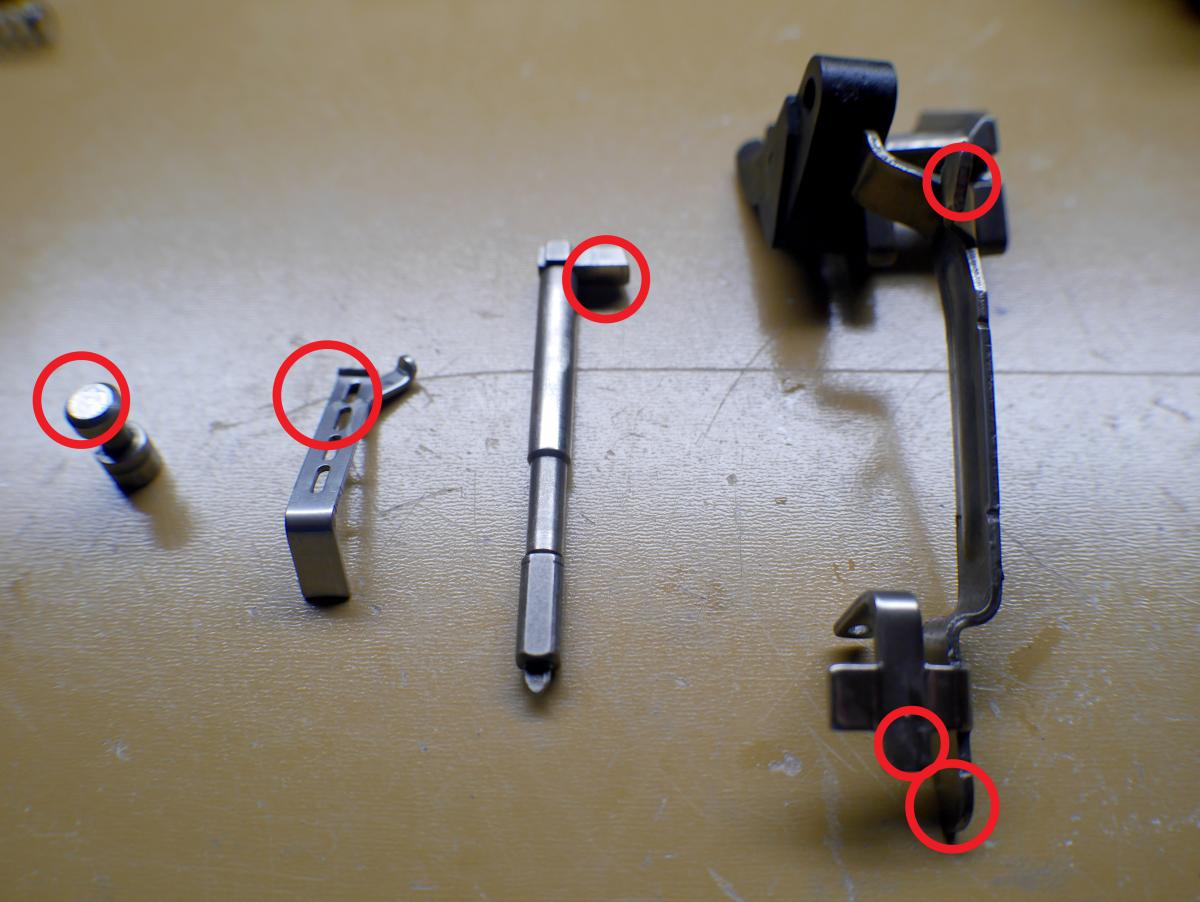

While Glock triggers will smooth out with time, I am a fan of polishing the connector and trigger bar surfaces. You keep the same trigger weight, but it becomes a smoother pull. Be very careful not to change the geometry of the connector or bar faces, just smooth them out.

I am not a fan of polishing the firing pin. Too easy to mess that up.

Here‘s a description:

[How-To] Glock 25 Cent Trigger Job

Easy step-by-step guide to polishing the correct trigger surfaces of the Glock 25 Cent Trigger Job with polishing compound and either hand or Dremel tools.

www.pewpewtactical.com

www.pewpewtactical.com

Last edited:

I have installed 2 of those Ghosts and it sure seems like it did not help much. Feels different.....maybe my expectations were too high. If anything yeah maybe a bit less ultimate pull, but even more grindy mid, right before break.It lightens the trigger pull to 3.5 lbs. it’s easy enough to install. Glocks aren’t complex.

But I’m not a fan for a carry gun. Modifications of trigger function in a duty/carry gun are a potential liability.

For a target/range/competition gun, sure, the Ghost connector is popular. I don’t have one. I’ve got a complete Alex trigger for G19/17 but never bothered to put it in. They‘re nice, but I bought it to make my G17 more of a competition gun and I haven’t done a pistol competition in a while.

While Glock triggers will smooth out with time, I am a fan of polishing the connector and trigger bar surfaces. You keep the same trigger weight, but it becomes a smoother pull. Be very careful not to change the geometry of the connector or bar faces, just smooth them out.

I am not a fan of polishing the firing pin. Too easy to mess that up.

Here‘s a description:

[How-To] Glock 25 Cent Trigger Job

Easy step-by-step guide to polishing the correct trigger surfaces of the Glock 25 Cent Trigger Job with polishing compound and either hand or Dremel tools.www.pewpewtactical.com

Completely agree on polishing all the contact and rubbing trigger parts. Get rid of any burrs and make it super smooth. Yes not really removing material. I have done this on all my Glocks and had done it on some P80's lost in the lake.

From my experience its hit or miss. Sometimes it makes the pull lighter and sometimes not. I have had a Ghost trigger pull harder than a factory unpolished. Funny Blue.....I have sold more guns and lost more $$$$$ shooting them for some times less than a couple thousands of rounds. I(ts all about wanting something newWhat is a Ghost 3.5 Connector and what does it do for a Glock trigger?

Thatl'betheday when you get a glock down to 3.5 pounds. And its peculiar that on all those videos they never polish the back vertical surface of the trigger bar where it slides against the vertical surface of the firing pin.It lightens the trigger pull to 3.5 lbs. it’s easy enough to install. Glocks aren’t complex.

Tenifer is not a finish but absorbed into the metal (it penetrates into the metal surface)...the black color finish is added on top of the Tenifer and has changed several times in the progression of GLOCK pistols...I don't believe GLOCKs have used Tenifer for some time but may use something similar...

That is what Glock instructors have explained in every Glock course I have ever taken over the years.

BlueOvalFitter

Thread starter

From just the 2 prior owned Glocks, I thought the trigger pull was very good.

The only item I will be adding to the G22 is a wider takedown bar.

The only item I will be adding to the G22 is a wider takedown bar.

BlueOvalFitter

Thread starter

Q? If the Gen 4 G22 slide finish is that nasty, ugly, chalky finish, will Glock be the best choice to have them apply the Gen 5 finish? Or, let a company like MIDDLEBRANCH MACHINE (https://middlebranchmachine.com/) Nitride the slide and maybe the barrel too?

The super durable Glock finish has been called the frying pan finish. They phased this out about 2012-2013 ish time frame. This was the extremely durable, hard to scratch , could carry for years and it looked new finish. This is NOT tenifer.

Tenifer was a metal treatment very similar to melonite. It is a heat treat Ferritic nitrocarburizing process. Once the slide was heat treated in this process, they THEN added the finish. The finish has changed many times over the years from parkerization, to frying pan finish, to who knows. Glock never said what the frying pan finish process was…. But…. It was basically a very durable Teflon frying pan coating as you would see on cookware.

I’ve owned 30 plus Glock firearms over the years and I could care less what finish it has. I consider them tools and don’t really care if they show wear or not. I’ve never had one rust… so the finish has been acceptable on all of them. I do have a few frying pan finish guns in my collection and not surprisingly, they still look almost new.

Tenifer was a metal treatment very similar to melonite. It is a heat treat Ferritic nitrocarburizing process. Once the slide was heat treated in this process, they THEN added the finish. The finish has changed many times over the years from parkerization, to frying pan finish, to who knows. Glock never said what the frying pan finish process was…. But…. It was basically a very durable Teflon frying pan coating as you would see on cookware.

I’ve owned 30 plus Glock firearms over the years and I could care less what finish it has. I consider them tools and don’t really care if they show wear or not. I’ve never had one rust… so the finish has been acceptable on all of them. I do have a few frying pan finish guns in my collection and not surprisingly, they still look almost new.

BlueOvalFitter

Thread starter

Like what I had on my early Gen 3 G21. That was the HOLY GRAIL FINISH, so I was told by fellow Glock Aholics. They said it was the real deal Tenifer finish, treatment, whatever.The super durable Glock finish has been called the frying pan finish. They phased this out about 2012-2013 ish time frame. This was the extremely durable, hard to scratch , could carry for years and it looked new. This is NOT tenifer.

Tenifer was a metal treatment very similar to melonite.

I am not sure what my original Gen 3's were coated with but yes super durable. Wipe down. Seems like they will never rust.

If you want to refinish/change color: Find a local Cerakote king in your area. A person who absolutely cares about quality work. Price shouldn't be crazy. I have guns that were Cerakoted 10+ years ago and the finish still looks good.

This 22 slide was from police surplus. It was OK, but had some "saddle wear". I shipped it to a guy kinda locally. Well around 4 hours drive. Price was nothing I even remember.

If you want to refinish/change color: Find a local Cerakote king in your area. A person who absolutely cares about quality work. Price shouldn't be crazy. I have guns that were Cerakoted 10+ years ago and the finish still looks good.

This 22 slide was from police surplus. It was OK, but had some "saddle wear". I shipped it to a guy kinda locally. Well around 4 hours drive. Price was nothing I even remember.

BlueOvalFitter

Thread starter

Pablo, l applaud you Sir! That is some very nice work!I am not sure what my original Gen 3's were coated with but yes super durable. Wipe down. Seems like they will never rust.

If you want to refinish/change color: Find a local Cerakote king in your area. A person who absolutely cares about quality work. Price shouldn't be crazy. I have guns that were Cerakoted 10+ years ago and the finish still looks good.

This 22 slide was from police surplus. It was OK, but had some "saddle wear". I shipped it to a guy kinda locally. Well around 4 hours drive. Price was nothing I even remember.

You understand what l'm looking for.

I have seen MIDDLEBRANCH'S work in person. This company's DEVIL is definitely in THE DETAIL!

I'm not looking to make this G22 a safe queen. I KNOW what a great Glock finish looks like and that's what l want! They say you get what you pay for, right? Well, l will pay to have a great finish applied to this G22 so that it will stand up to what La. weather throws at it.

I don't get any more excited about my garden shovel scratched than my pistols. As long as it digs or shoots.

Do you feel the same about your car, as long as it runs?I don't get any more excited about my garden shovel scratched than my pistols. As long as it digs or shoots.

the black "finish" is NOT Tenifer...Tenifer is clear and absorbed in the metal...the black "finish" everyone likes or doesn't has changed several times over the years and is just that...a finish...on top of the metal treated with Tenifer or whatever GLOCK appears to be using currently...

Bill

Bill

lol..good oneDo you feel the same about your car, as long as it runs?

Third or forth time I have read this here............please explain this to me at the atomic level. I cannot get my head around this. Steel simply is not porous and does not absorb anything.....absorbed in the metal...

I frankly think it is some level of BS.

The Tenifer process is technically a case hardening process.Third or forth time I have read this here............please explain this to me at the atomic level. I cannot get my head around this. Steel simply is not porous and does not absorb anything.

I frankly think it is some level of BS.

Ferritic nitrocarburizing - Wikipedia

No more Tenifer on Glocks ?

Last edited:

Similar threads

- Replies

- 14

- Views

- 1K

- Replies

- 17

- Views

- 5K

- Replies

- 5

- Views

- 4K

- Replies

- 49

- Views

- 4K