Engine discharge air temp is directly related to discharge speed. The hotter the discharge air, the faster we can move it before stagnation, choking or a limiting shock wave forms in the duct.

Although most pilots don't have the instrumentation necessary to see the relationship between duct air speed, temperature, pressure and airspeed, I promise, it is closely related.

In our Gulfstream jets, I've seen 250Kts TAS at low altitudes. with equal inlet and outlet pressures! This happens because the heat of combustion effectively allows the discharge velocity to be very high without stagnating in the duct. (remember F=MA)

The Afterburner (or reheat) simply heats up the air in the duct, to 2200ºF or more. This raises the speed of sound to 2000+MPH (the stagnation point) and expands the air. Without changing the load or pressure on the engine itself, it can double the thrust and substantially improve top speed.

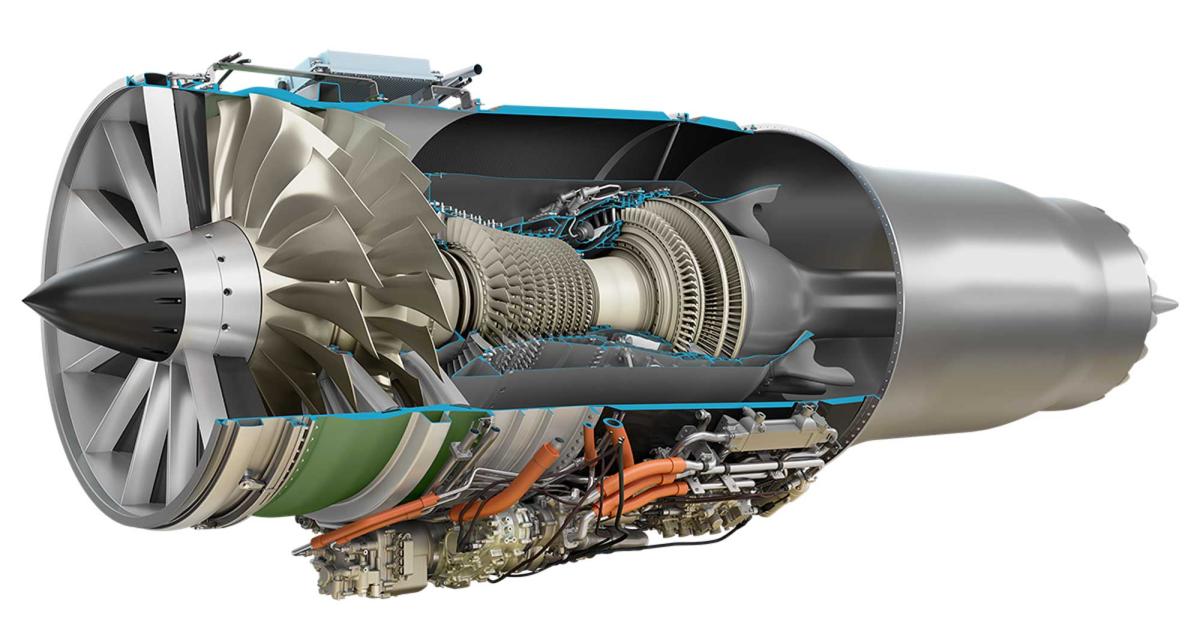

Another interesting way to go fast is to use a multi stage fan. This heats the air via compression, and therefore increases duct discharge velocity. The hotter we make the air, the faster we can go.

This is why driving a turbofan with an electric motor is generally limited to 350Kts. The discharged air is cold.

On our faster corporate jets, we try hard to mix hot exhaust with cold fan air, well before the nozzle.