With just over 100k if very concerned about the high iron. Anyone know why this is? The lead, copper, and tin have calmed down to normal levels but this tells me there is most likely wear within the cylinder walls. Where else would this occur? Also this engine is strong, has no wierd sounds, and does not burn a drop of oil between changes.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ford 2V 4.6L V8 @ 105k miles; QS 5w-20 conventional @ 3k miles w/ high Fe

- Thread starter Fordiesel69

- Start date

What kind of oil are you using? And was it the same oil for all of those runs?

have you ever opened up the engine? Looked under the valve covers?

OVERKILL

$100 Site Donor 2021

Why are you considering this "high"?

With just over 100k if very concerned about the high iron. Anyone know why this is? The lead, copper, and tin have calmed down to normal levels but this tells me there is most likely wear within the cylinder walls. Where else would this occur? Also this engine is strong, has no wierd sounds, and does not burn a drop of oil between changes.

OP, what vehicle is this in and what are the operating conditions? What was Blackstone's comments? If it is exposed to towing or short trips this can increase the iron in the oil...

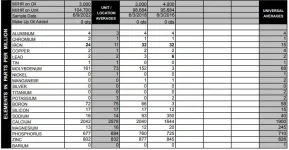

IMO, this is not very high. If there was a significant issue the iron would be several times higher than the right hand column not just 1.5 or 2x's. Keep in mind the universal averages are from all the vehicles with this engine, so some will be higher, some will be lower.

just my $0.02

Exactly. The acceptable levels for iron are up to 150 PPM.Why are you considering this "high"?

OVERKILL

$100 Site Donor 2021

On a longer drain interval, yes, 150ppm is generally the condemnation limit used by Doug Hillary during his testing. Those were long (60,000 mile) intervals however. Mileage has to be factored in. However, I don't see 24ppm as alarming, or unusual for this piece of equipment, given its history.Exactly. The acceptable levels for iron are up to 150 PPM.

Allow me to expand on that:

- The first interval shown is 2016, and has 95,684 miles

- The second interval shown is two years, but only 3,000 miles later, 98,684 miles

- This third interval is another four years, but only 6,000 miles later, 104,700 miles

So, this vehicle appears to accrue about 1,500 miles a year, that's only 125 miles a month. I suspect that it sits a LOT. When an engine sits, corrosion happens, particularly on ferrous surfaces like cylinder walls, cam lobes...etc. Bores, that have less in the way of oil film left on them will of course corrode quicker. With that in context, these results are not only not of concern, but actually look pretty good.

Fordiesel69

Thread starter

Its one of the 2008 CVPI garage queens. It does not get a lot of use but when it does, I take it on 1-2 hr trips. It never gets idled, or used for severe duty. It has 252 real idle hours. It was never used as a patrol car and confirmed to be a criminal intelligence car so in theory it should have a very good engine as it always saw highway travel. But it has the worst UOA of all my cars, even the harder used ones that get even less use.

Assuming the reported mileage to be correct, if you consider iron generation in ppm/1000 hours rather than as an absolute, the average is 8.9 ppm/1000 hr. Even if you considered the values as absolute, they are not even close to caution. Based on calcium and molybdenum levels, the 2016 sample may be a different oil.

- Joined

- Jul 11, 2014

- Messages

- 4,117

What oil and ending visc? What filter?

Can you include Blackstone's comments?With just over 100k if very concerned about the high iron. Anyone know why this is? The lead, copper, and tin have calmed down to normal levels but this tells me there is most likely wear within the cylinder walls.

I'd assume they don't have any problem with this analysis.

Again, as others have asked, why do you think <35 ppm is high?

OVERKILL

$100 Site Donor 2021

No two engines are the same, I wouldn't worry about it being different from the others. In fact, if it is a "tighter" engine, that might explain it being a bit higher as a result of it sitting. Unless it is making some funny noises or there's some other reason to suspect there's a mechanical issue, I'd say it's just fine. There's nothing alarming in that report.Its one of the 2008 CVPI garage queens. It does not get a lot of use but when it does, I take it on 1-2 hr trips. It never gets idled, or used for severe duty. It has 252 real idle hours. It was never used as a patrol car and confirmed to be a criminal intelligence car so in theory it should have a very good engine as it always saw highway travel. But it has the worst UOA of all my cars, even the harder used ones that get even less use.

dnewton3

Staff member

I have a lot of experience with these engines. Owned a couple of MGMs ran out to high mileage, and drove CVPIs on duty for about a decade. I also have about 600 UOAs on these engines from all manner of various sources.

These Fe rates are high for sure. It's typical to see less than 2ppm/1k miles of Fe in these engines. I, myself, have run 10k mile OCIs and seen at or less than 1ppm/1k miles. So these UOAs are clearly out of the norm; 8 to 10 ppm Fe per 1k miles is NOT normal for these engines. Question is why?

First, does it make any noise whatsoever at the front timing cover? These engines, while very reliable, can have the timing chain guides wear through; one the chain starts eating the metal backer, there's tons of Fe shed. You can pull the valve covers and peer down the front with a borescope, etc.

It's possible that long periods of sitting are causing the Fe, but it's not my first inclination to believe this.

Are you using any additives that would skew the data?

The silicon seems high for 3k to 4k miles. Have you checked the air intake tract for leaks?

These Fe rates are high for sure. It's typical to see less than 2ppm/1k miles of Fe in these engines. I, myself, have run 10k mile OCIs and seen at or less than 1ppm/1k miles. So these UOAs are clearly out of the norm; 8 to 10 ppm Fe per 1k miles is NOT normal for these engines. Question is why?

First, does it make any noise whatsoever at the front timing cover? These engines, while very reliable, can have the timing chain guides wear through; one the chain starts eating the metal backer, there's tons of Fe shed. You can pull the valve covers and peer down the front with a borescope, etc.

It's possible that long periods of sitting are causing the Fe, but it's not my first inclination to believe this.

Are you using any additives that would skew the data?

The silicon seems high for 3k to 4k miles. Have you checked the air intake tract for leaks?

Wear rates are most useful for specific vehicles. They don't fit averages, especially universal averages. They depend on maintenance habits, oil change intervals, operating environment, driving habits, etc. The wear rates of this vehicle are consistent across the intervals. With end-of-cycle analyses that's really what you want to see.

A vehicle that generates 2 ppm/1000 hours carefully operated in California may generate 8 ppm/1000 hours in the hands of another operator in Maine. Further, without a lot of other elemental indicators showing problems, as OVERKILL suggests, there may be some corrosion involved in iron generation based on idle time.

A vehicle that generates 2 ppm/1000 hours carefully operated in California may generate 8 ppm/1000 hours in the hands of another operator in Maine. Further, without a lot of other elemental indicators showing problems, as OVERKILL suggests, there may be some corrosion involved in iron generation based on idle time.

dnewton3

Staff member

Respectfully, I disagree in this specific applicaiton.Wear rates are most useful for specific vehicles. They don't fit averages, especially universal averages. They depend on maintenance habits, oil change intervals, operating environment, driving habits, etc. The wear rates of this vehicle are consistent across the intervals. With end-of-cycle analyses that's really what you want to see.

A vehicle that generates 2 ppm/1000 hours carefully operated in California may generate 8 ppm/1000 hours in the hands of another operator in Maine. Further, without a lot of other elemental indicators showing problems, as OVERKILL suggests, there may be some corrosion involved in iron generation based on idle time.

The 4.6L 2v mod motors are typically very consistent in wear rates. I do agree that extreme examples can always be anecdotally shown, but overall the 4.6L is VERY proven and does not exhibit wear rates typically anywhere near this high as seen in this UOA above.

Again, I have over 600 UOAs from this engine series, seeing just about every concievable environment, oil brand and grade, severity factors, etc. I know these engines quite well. When these engines are in good operational condition, they should typically see between 1-3 ppm/1k miles of Fe, regardless what oils, filters, and use factors they experience.

https://bobistheoilguy.com/used-oil-analysis-how-to-decide-what-is-normal/

There is a distinct difference between micro data and macro data.

The OP does not have anywhere near enough data for solid analysis; three reports are way too few to get any understanding of the average or std dev values. However, there is PLENTY of macro market data, as seen in the linked "normalcy" article, specifically for the 4.6L Fords.

We don't know what is causing the Fe to be high, but we can say with absolute assurance that the wear rates this engine is experiencing are WAY out of line with the vast majority of 4.6L engines out there. This is NOT "normal" wear.

The driving pattern here (1-2 hours) rules out massive condensation issues because it gets plenty warm enough to evaporate the moisture out. And, because engines are sealed well these days (no open PCV), there's not a lot of moisture ingestion just sitting still for long periods. He has three other vehicles with the 4.6L engine (two more CVPIs and I presume the F-150 does also). And he's mentioned that the other vehicles see less use, and more severe use, and yet have better UOAs with lower Fe. So this is NOT a matter of it just "sitting around"; otherwise we'd see high Fe in ALL his vehicles with the 4.6L engines.

To be fair, there's no reason to panic here. But the data is telling us that something is askew; it's not normal to the engine series. Rather than just brush it off, the OP should be looking for several tell-tale causes (such as the timing chain guides, and perhaps a bore scope in the cylinders to make sure there's no scuffing; and the air intake leak?). If all those potential causes are eliminated, and no issue is found, only then can he consider this "normal" for his unique engine. With only three UOAs on this 2008 CVPI, there's no where enough data to do micro analysis. So we cannot know what is average or stdev for this engine. If all common causes of high wear are ruled out by detailed investigation, then a conclusion could be drawn that this engine may have a machining defect which is simply causing high wear. It's difficult to believe that the cylinders are wearing, but the aluminum pistons are not. It's difficult to understand how a cam could be wearing, but the aluminum bearings are not (the Ford mod motors do not have the typical "babbit" bearings with Cu and Pb; they are aluminum).

This engine, despite it's high Fe counts, could last a long time just as many other 4.6L engines do. But these three UOAs are telling us that SOMETHING IS NOT NORMAL for the engine family.

Last edited:

dnewton3

Staff member

A few questions for the OP ...With just over 100k if very concerned about the high iron. Anyone know why this is? The lead, copper, and tin have calmed down to normal levels but this tells me there is most likely wear within the cylinder walls. Where else would this occur? Also this engine is strong, has no wierd sounds, and does not burn a drop of oil between changes.

- what oil brand/grade was used (I'll update the title for you).

- what does it mean when you say "The lead, copper, and tin have calmed down to normal levels ..."? Do you have other UOAs where these were also elevated?

Last edited:

I would switch to QSFS 5w30 or QS HM blend 5w30 see of it helps

Similar threads

- Replies

- 24

- Views

- 3K

- Replies

- 8

- Views

- 3K

- Locked

- Replies

- 29

- Views

- 9K

- Locked

- Replies

- 11

- Views

- 7K

- Replies

- 20

- Views

- 14K