OVERKILL

$100 Site Donor 2021

Originally Posted By: ekpolk

Originally Posted By: OVERK1LL

...

The E-core IS a Champ Labs design.........

I doubt it would ever happen with a Fleetguard or Donaldson filter. Heavy diesel filters aren't built as "skimpily" as some of their Passenger Car counterparts seem to be......

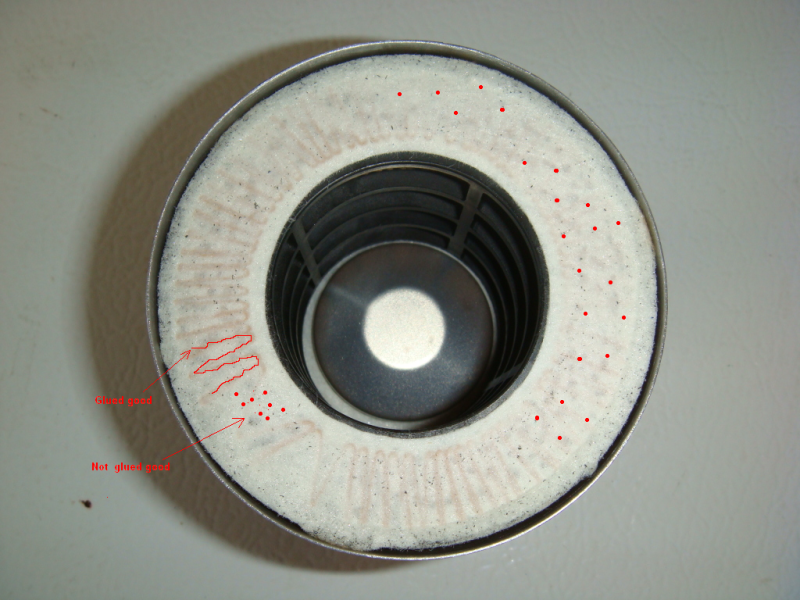

C'mon, you know what I meant -- the CL filters with the pleats firmly cemented into the metal end caps, and heavy steel centertube. As in M1, KN, STP, VC, Bosch (some), and so on...

Yeah, but I had to give you a hard time

Originally Posted By: OVERK1LL

...

The E-core IS a Champ Labs design.........

I doubt it would ever happen with a Fleetguard or Donaldson filter. Heavy diesel filters aren't built as "skimpily" as some of their Passenger Car counterparts seem to be......

C'mon, you know what I meant -- the CL filters with the pleats firmly cemented into the metal end caps, and heavy steel centertube. As in M1, KN, STP, VC, Bosch (some), and so on...

Yeah, but I had to give you a hard time