I like having a high-tech vehicle with throttle-by-wire, dynamic stability control, electric-assisted steering, etc. Old technology is for museums! These systems are getting more refined and lower-cost all the time. My 2009 fairly-inexpensive car has all the technology of my parent's 2004 BMW 3-series that cost three times as much.

And we do like our high-tech synthetic oils, don't we?

As for diagnostics - well, a light comes on and you read a code. The TBW system in the Suzuki has 14 codes.

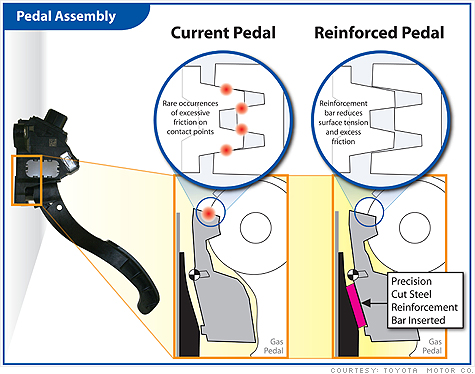

I also think it's interesting to note that the Toyota fault (as so far identified) is *purely* mechanical in nature. Given where the blame has been generally placed do we not see the irony there?

And we do like our high-tech synthetic oils, don't we?

As for diagnostics - well, a light comes on and you read a code. The TBW system in the Suzuki has 14 codes.

I also think it's interesting to note that the Toyota fault (as so far identified) is *purely* mechanical in nature. Given where the blame has been generally placed do we not see the irony there?