Are you doing any UOA’s along with this?Finally got around to try an overkill magnetic diy filter setup. I bought 40 N42SH bars to take it up a notch for 360 degree coverage since my last experience using samarium cobalt disc on the baseplate caught some magnetic dust on the last Donaldson i cut opened. Looking forward to see whats inside at 10k miles.

View attachment 241085

View attachment 241086

View attachment 241087

View attachment 241088

View attachment 241089

View attachment 241090

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Check out my magnets on my oil filter

- Thread starter cman

- Start date

- Joined

- Oct 3, 2023

- Messages

- 865

Are you doing any UOA’s along with this?

Yep with particle counts as well.

Finally got around to try an overkill magnetic diy filter setup. I bought 40 N42SH bars to take it up a notch for 360 degree coverage since my last experience using samarium cobalt disc on the baseplate caught some magnetic dust on the last Donaldson i cut opened. Looking forward to see whats inside at 10k miles.

View attachment 241085

View attachment 241086

View attachment 241087

View attachment 241088

View attachment 241089

View attachment 241090

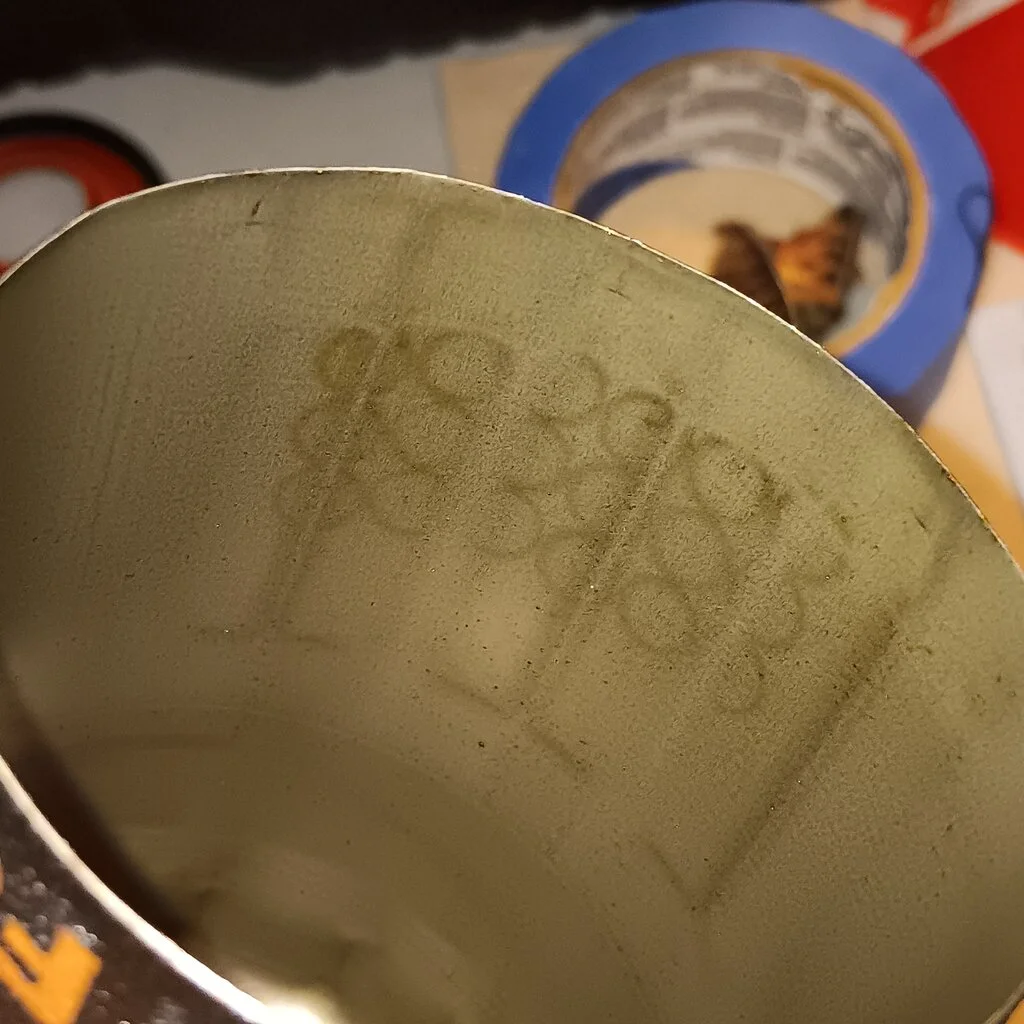

I am still rocking ebay magnets and they seemingly been working for me. This was not even a full run

Maybe it cause a black hole inside the filter and help close up the leaf spring leak gap ...Finally got around to try an overkill magnetic diy filter setup. I bought 40 N42SH bars to take it up a notch for 360 degree coverage ....

- Joined

- Oct 3, 2023

- Messages

- 865

I am still rocking ebay magnets and they seemingly been working for me. This was not even a full run

View attachment 241112

Thats quite a bit of iron for a short run, heres the amount of metal the magnets caught in 5k on the Yaris.

Maybe it cause a black hole inside the filter and help close up the leaf spring leak gap ...

I'm not so worried about the leaf spring sealing, I'll let the particle count analysis at 10k determine my judgement and course of action. Will likely run another Donaldson P551132 or Fram FS3600 for an additional 5k to see how well it cleans up should particles in the lower range if they read out higher than expected.

This experiment is more of a hobby and curiosity, whether the outcome long term contributes to engine longevity or not is entertainment and story to share if I live long enough to.

^^^

Doesn't look too bad. How many miles are on he engine? Even with a broken in engine, there will be some of that because no matter what you do there is always wear going on from rubbing parts (asperities) in the boundary and mixed lubrication regimes.

Doesn't look too bad. How many miles are on he engine? Even with a broken in engine, there will be some of that because no matter what you do there is always wear going on from rubbing parts (asperities) in the boundary and mixed lubrication regimes.

Thats quite a bit of iron for a short run, heres the amount of metal the magnets caught in 5k on the Yaris.

Oh no, we're going to have to get into comparative analysis of magnetic performance taking into account can thickness.

I'm not so worried about the leaf spring sealing, I'll let the particle count analysis at 10k determine my judgement and course of action. Will likely run another Donaldson P551132 or Fram FS3600 for an additional 5k to see how well it cleans up should particles in the lower range if they read out higher than expected.

This experiment is more of a hobby and curiosity, whether the outcome long term contributes to engine longevity or not is entertainment and story to share if I live long enough to.

I appreciate you doing the particle counts and agree that it is the best course of action to make determinations for your particular circumstances. And that it likely won't matter anyway.

Going off the BR data (which although it is flawed, I think for the high efficiency filters it is more usable), the worst performing leaf spring was apparently on the Royal Purple and I number crunched that it became a 91.3% efficient filter in the 21-38 micron range. That compares to 99.3% for the 20-40 micron range through Ascent's testing.

However, both Ascent's and BR's Royal Purple filter were metal on metal sealing. So either the BR Royal Purple was of worse quality or their testing was flawed. The BR Amsoil did perform as expected while the Endurance and Ultra were in between.

My own view is that since we can't see the size of the gap and the manufacturing has gotten worse, we don't know how bad the filtering performance will get. So while the current data suggests they are better than a Purolator Boss, in any individual case, it might be as bad or even worse than a Wix XP

- Joined

- Oct 3, 2023

- Messages

- 865

^^^

Doesn't look too bad. How many miles are on he engine? Even with a broken in engine, there will be some of that because no matter what you do there is always wear going on from rubbing parts (asperities) in the boundary and mixed lubrication regimes.

View attachment 241121

I'm well aware of the Stribeck curve wear regime. The car itself is my 100 mile daily that currently has 155K miles. Surprisingly has an engine that could take such long tripping abuse with some spirited wide open throttle runs and shed so little metal as seen on the photo. Just wished Toyota still make these cars and engine.

- Joined

- Oct 3, 2023

- Messages

- 865

Oh no, we're going to have to get into comparative analysis of magnetic performance taking into account can thickness.

I appreciate you doing the particle counts and agree that it is the best course of action to make determinations for your particular circumstances. And that it likely won't matter anyway.

Going off the BR data (which although it is flawed, I think for the high efficiency filters it is more usable), the worst performing leaf spring was apparently on the Royal Purple and I number crunched that it became a 91.3% efficient filter in the 21-38 micron range. That compares to 99.3% for the 20-40 micron range through Ascent's testing.

However, both Ascent's and BR's Royal Purple filter were metal on metal sealing. So either the BR Royal Purple was of worse quality or their testing was flawed. The BR Amsoil did perform as expected while the Endurance and Ultra were in between.

My own view is that since we can't see the size of the gap and the manufacturing has gotten worse, we don't know how bad the filtering performance will get. So while the current data suggests they are better than a Purolator Boss, in any individual case, it might be as bad or even worse than a Wix XP

Problem I have with Brand Ranks testing is their somewhat lack of control, weird way publication of results. For example, the entire industry takes into account of ISO 4406 which targets for the first 3 particle size range, in which Brand Ranks entirely discards and only show ranges in the 21 micron and up which is completely backwards where as fluid cleanliness levels from a critical industry standard standpoint are within the >4, >6, and >14 micron range. Without the full the picture available from their particle counting results I can only see as for entertainment.

Gathering real world results takes lots of time and money in comparison to a garage test rig. Since that horse has been beaten many times in other topics I won't continue talking about their videos.

I'm not so worried about leaf spring sealing that goes on in the other topic. Its fairly known by now that is a problem that should have been corrected from a design engineering, manufacturing, and quality control screening standpoint. I won't drag that discussion here to hijack this topic.

I've made the same basic comment on the ISO 4406 data they use and compare. They are getting the ISO PC data, so why not show it as it's presented in the ISO 4406 test results.Problem I have with Brand Ranks testing is their somewhat lack of control, weird way publication of results. For example, the entire industry takes into account of ISO 4406 which targets for the first 3 particle size range, in which Brand Ranks entirely discards and only show ranges in the 21 micron and up which is completely backwards where as fluid cleanliness levels from a critical industry standard standpoint are within the >4, >6, and >14 micron range. Without the full the picture available from their particle counting results I can only see as for entertainment.

I've made the same basic comment on the ISO 4406 data they use and compare. They are getting the ISO PC data, so why not show it as it's presented in the ISO 4406 test results.

Another thing that would be nice to have is the tabular efficiency data for all filters from the Ascent testing. I know that Andrew shared it with a couple of people here.

Last edited:

Problem I have with Brand Ranks testing is their somewhat lack of control, weird way publication of results. For example, the entire industry takes into account of ISO 4406 which targets for the first 3 particle size range, in which Brand Ranks entirely discards and only show ranges in the 21 micron and up which is completely backwards where as fluid cleanliness levels from a critical industry standard standpoint are within the >4, >6, and >14 micron range. Without the full the picture available from their particle counting results I can only see as for entertainment.

Gathering real world results takes lots of time and money in comparison to a garage test rig. Since that horse has been beaten many times in other topics I won't continue talking about their videos.

I'm not so worried about leaf spring sealing that goes on in the other topic. Its fairly known by now that is a problem that should have been corrected from a design engineering, manufacturing, and quality control screening standpoint. I won't drag that discussion here to hijack this topic.

Would it not be a safe assumption that the higher the particle filtration results at 20 microns and up that it would also perform better for the 4 - 14 range? Also, at what point does it become somewhat pointless to care? If ones oil / additives are doing their job to keep wear metals down to ideally around 2 - 3 ppm of iron per 1k miles, I would think the engine will mostly have a major mechanical failure long before the metal wear is really a factor in longevity.

Very nice. Thanks for the pics!! Nice microgard too.Finally got around to try an overkill magnetic diy filter setup. I bought 40 N42SH bars to take it up a notch for 360 degree coverage since my last experience using samarium cobalt disc on the baseplate caught some magnetic dust on the last Donaldson i cut opened. Looking forward to see whats inside at 10k miles.

View attachment 241085

View attachment 241086

View attachment 241087

View attachment 241088

View attachment 241089

View attachment 241090

I wonder if there's any concern about magnetizing small particles that could then escape from the magnet and stick to parts you don't want them to.

None.

It takes quite a bit of intentional rubbing to temporarily magnetize an object which it then loses very quickly when exposed to any heat.

Deleted

I don't think rubbing is necessary to magnetize small particles like it might be with something like a screwdriver. Contact is enough in my experience.None.

It takes quite a bit of intentional rubbing to temporarily magnetize an object which it then loses very quickly when exposed to any heat.

I don't think rubbing is necessary to magnetize small particles like it might be with something like a screwdriver. Contact is enough in my experience.

Let's say a particle manages to become magnetized.

It then has to escape being held where it was stuck to begin with which isnt likely.

Let's say it does escape though, and makes it through the filter media and back into circulation.

It then somehow has to manage to permanently keep its magnetism, which it wont due to heat, and the nature of induced magnetism.

Last edited:

You and me both brother. I will argue the 1nzfe is simply one of the best engines period.Just wished Toyota still make these cars and engine.

Similar threads

- Replies

- 16

- Views

- 928

- Replies

- 35

- Views

- 7K

- Replies

- 25

- Views

- 4K

- Replies

- 41

- Views

- 2K