You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BOBISTHEOILGUY FILTER TESTS

- Thread starter BOBISTHEOILGUY

- Start date

- Status

- Not open for further replies.

No, I assume that I have a full filter and oil channels that has an open end drop to the oil pan. I also think that the back pressure of the oil distribution depends on enough oil going thru the filter or bypass to build pressure against the open-ended distribution paths.quote:

Perhaps ..but you're going on the assumption of an empty oil filter pushing into a void. This is rarely the case. You have no idea of what back pressure the downstream oil system puts on the media.

I agree that this is needed to not poke holes in the filter medium. But when the oil leaves the filter the velocity is right back up there. What's your guess? A couple of inches a second? More? Less? Varies with rpm?quote:

It's also experiencing a radical drop in velocity in the filter can. If you strectch out the filter media into a panel (like many of out air filters have) you would have a, less than, 1/2 diameter flow spreading out over 90-150 square inches of media. Sorta like being on a one lane highway and then having the road broaden out into 50 lanes wide ..and then choking back into 1 lane again. Traffic, so to speak, is at a crawl through the filter.

How is the oil being forced past the "sprung" restrictor when the oil is warm? Is there a thermostat there or what? Now I'm confused? If oil flows easier warm it would tend to go thru the by-pass filter easier and not build the pressure to overcome what you call the restrictor.quote:

Not really The sprung restriction is to force flow to the bypass when the oil is warm. The oil pump IS going to pump what it is going to pump. When warm ...it flows like water. If they didn't have that sprung restrictor ..it would take many miles to accumulate enough resistance in the ff for it to route enough oil through the bypass filter.

With both filters flowing into the same return when does oil go thru the ff? Does the ff have a larger micron filter than the by-pass filter? What forces the oil to bypass going thru the by-pass filter to overcome the spring and ball then go thru the full flow?

I don't believe in the correlation of electron flow in resistors to fluid flow thru filters. Why would they design the flow to split to 16% to the ff filter and 84% to the by-pass filter anyways?

Can you actually see daylight thru the line from block to the first filter, the by-pass filter? If not it would be interesting to have a couple of block adapters on the Amsoil DR, to see exactly which way and where the flow goes and is blocked.

I believe they use something like MIL-H-5606 hydraulic fluid. So when they conduct filter tests, it's with a fluid of about 23 cSt at room temperature, which is equivalent to the typical 5w30 oil at 65-70C (149-158F).quote:

Originally posted by edwardh1:

Purolater says:

PureOne filters meet the flow requirements of automotive applications. We

test our filters per SAE specification HS806 Chapter 1, and the standard

flow rate requirement that we follow states that the pressure differential

(between inlet and outlet) shall not exceed 3.0 psi at a flow rate of 3.0

gpm. On the PL30001 filters, flow restriction is 0.8 psi (avg) at 3.0 gpm.

++++++++++++++++++

I bet this test is done at an elevated temperature - anyone know??

Why aren't we using an SAE test rather than a lets make up out own?????

[ February 03, 2005, 09:35 PM: Message edited by: 427Z06 ]

- Joined

- Sep 28, 2002

- Messages

- 39,798

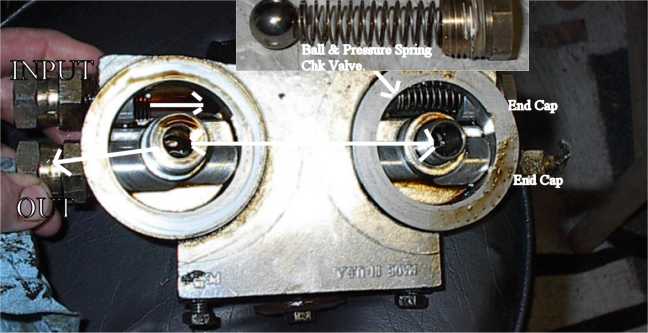

Okay ..input runner of remote mount ... first in line for a down leg is BYPASS FILTER ...same runner "further in" is SPRUNG RESTRICTER -beyond sprung restrictor - downleg to FF.quote:

How is the oil being forced past the "sprung" restrictor when the oil is warm? Is there a thermostat there or what? Now I'm confused? If oil flows easier warm it would tend to go thru the by-pass filter easier and not build the pressure to overcome what you call the restrictor.

Oil cold high viscosity ...can not go through bypass filter. Pressure, elevated due to temp, PUSHES RESTRICTOR BACK - OPENS ACCESS TO FF.

Oil hot. Oil flows much easier through BYPASS filter ...restrictor valve DOES NOT move as FAR back due to reduced pressure. MAX flow goes to bypass filter ..remainder (which will still be MORE) goes to FF.

It's not identical ..but it works for demonstration purposes. You would have to look at viscosity as a reactive component ..impedence. A 1/32 hole is a greater restriction @ 32°F then it is @ 212°F. Likewise the flow through different media densities will not be in the same proportion at different viscosities. They have a relationship at a given viscosity. If you applied band pass and band reject resonate principles to the two filters run in parallel, the bypass would appear to be an "open", while the ff would appear to be a shunt if the viscosity was extreme. As the viscosity was reduced, the impedence of the dense bypass filter would be reduced and it would "pass" more through it at the same applied pressure. The sprung restrictor raises the impedence of flow to the ff. So when the oil is thick the ff is the only place it can go (almost completelY) ..when the oil is thin the ff has artificial resistance of the sprung valve to make the bypass "pass" more fluid (still much less).quote:

I don't believe in the correlation of electron flow in resistors to fluid flow thru filters.

You don't. You get about 15-20%. The biasing valve just simulates a restriction on the ff to induce more flow (the maximum) through the bypass at all times. Whatever the bypass cannot handle, due to flow/viscosity, will go through the ff. This flow will be the majority in all cases (the ff).quote:

Why would they design the flow to split to 16% to the ff filter and 84% to the by-pass filter anyways?

Thinks of garden hose with two outlets. One normal sized (ff) one 1/16 of an inch (bypass). You want more flow out of the 1/16 inch outlet ..so you put your thumb partially over the regular outlet (creating an artificial restriction) to induce MORE flow through the 1/16th opening. Now just regulate the flow on that hose so that it MUST move so much water a minute (positive displacement) and you will only be able to close off the larger opening so far because you're not strong enough to resist the positive flow (the sprung restrictor.

Btw- just in case you're confused about this point .....the bypass referred to in this post is only called a bypass due to the filter design. It is not run as a "bypass filter" in the common sense of the nomenclature. A bypass filter typically taps off of a pressure point (sender port, etc.) and then just returns to the sump (valve cover, etc.) after going through the dense media.

This setup is a ff and bypass type filter run in parallel.

This may answer your question. Remember the oil LEAVES the filters through the CENTER

Note how the filter mount on the right is COMPLETELY BLOCKED OFF by the sprung restrictor.

If you didn't do this ..it would greatly reduce the effectivness of the bypass filter UNTIL the ff collected enough contamination to make the bypass a little more appealing to flow.

Did that make any more sense???

Clear as oil from a 25K OCI. You related to Rube Goldberg by any chance?

All kidding aside, it just dawned on me why this is a design one could get fond of. I.e., all the oil from the pump goes to the engine instead of having to bleed some off to feed the bypass filter.

All theory aside, how did it end up working for you in the real world?

All kidding aside, it just dawned on me why this is a design one could get fond of. I.e., all the oil from the pump goes to the engine instead of having to bleed some off to feed the bypass filter.

All theory aside, how did it end up working for you in the real world?

- Joined

- Sep 28, 2002

- Messages

- 39,798

I didn't use this mount. I just took the threaded inserts and used them in my PermaCool dual mount (which I already had plumbed).

That's why I know that the bypass won't see much flow until the ff gets some miles on it in the absense of the biasing valve.

It only got hot on one localized spot when both filters were new. When I changed it out (12.5k) both were fully saturated.

That's why I know that the bypass won't see much flow until the ff gets some miles on it in the absense of the biasing valve.

It only got hot on one localized spot when both filters were new. When I changed it out (12.5k) both were fully saturated.

Let me add a bit from my days selling Luber-finer by-pass units.

The model 750 was the largest and used in the trucking industry. Model 78 was the smallest capacity unit.

The way that the flow was "restricted" was because each unit had an orifice at the pack hold down "T-handle".

The original designs had a brass metering orifice. The current design has moved the metering orifice to the inlet fitting.

The unit saw 100% of the oil pressure but the orifice only allowed a small amount of oil to be filtered. The return line was plumbed back to the oilpan to "by-pass" the oil that is used to lubricate the engine. You wanted no more than 10% of the oil capacity to be bled off and filtered in the by-pass unit.

It looks to me, from the picture of the dual head assembly, as though the second spring on the "by-pass" side would have a much higher tension and work the same as the metering orifice. ( not the way I would do it, but there you go). The oil from the "secondary" side with a tighter tension spring could allow someone to put a much more efficient spin on filter on that side to do much the same as the "by-pass" filters on the market.

Gary..is that how this head assembly works? That's my guess...

The model 750 was the largest and used in the trucking industry. Model 78 was the smallest capacity unit.

The way that the flow was "restricted" was because each unit had an orifice at the pack hold down "T-handle".

The original designs had a brass metering orifice. The current design has moved the metering orifice to the inlet fitting.

The unit saw 100% of the oil pressure but the orifice only allowed a small amount of oil to be filtered. The return line was plumbed back to the oilpan to "by-pass" the oil that is used to lubricate the engine. You wanted no more than 10% of the oil capacity to be bled off and filtered in the by-pass unit.

It looks to me, from the picture of the dual head assembly, as though the second spring on the "by-pass" side would have a much higher tension and work the same as the metering orifice. ( not the way I would do it, but there you go). The oil from the "secondary" side with a tighter tension spring could allow someone to put a much more efficient spin on filter on that side to do much the same as the "by-pass" filters on the market.

Gary..is that how this head assembly works? That's my guess...

- Joined

- Sep 28, 2002

- Messages

- 39,798

Well, they use it to "help" the oil go through the bypass filter instead of just taking the easier path through the ff.

Do you have any thoughts or insights into this??

Do you have any thoughts or insights into this??

quote:

Originally posted by edwardh1:

Purolater says:

PureOne filters meet the flow requirements of automotive applications. We

test our filters per SAE specification HS806 Chapter 1, and the standard

flow rate requirement that we follow states that the pressure differential

(between inlet and outlet) shall not exceed 3.0 psi at a flow rate of 3.0

gpm. On the PL30001 filters, flow restriction is 0.8 psi (avg) at 3.0 gpm.

++++++++++++++++++

I bet this test is done at an elevated temperature - anyone know??

Why aren't we using an SAE test rather than a lets make up out own?????

I believe they use something like MIL-H-5606 hydraulic fluid. So when they conduct filter tests, it's with a fluid of about 23 cSt at room temperature, which is equivalent to the typical 5w30 oil at 65-70C (149-158F).

Gary,quote:

Btw- just in case you're confused about this point .....the bypass referred to in this post is only called a bypass due to the filter design. It is not run as a "bypass filter" in the common sense of the nomenclature. A bypass filter typically taps off of a pressure point (sender port, etc.) and then just returns to the sump (valve cover, etc.) after going through the dense media.

Since it is a bypass filter it will go into by-pass mode if the oil pressure is greater than 8-12psi on the high side. That would mean that the spring restrictor would have to open with less pressure than the by-pass of the bypass filter.

Does that mean that the bypass filter has a smaller micron filter than the full-flow? What causes the flow to divert to the full-flow?

Do both filters have the same micron media? So that oil is run parallel from both filters back into engine block? With the restrictor controlling how much oil goes to the full-flow, with less flowing thru the full-flow as it warms up?

Filter guy,quote:

The unit saw 100% of the oil pressure but the orifice only allowed a small amount of oil to be filtered. The return line was plumbed back to the oilpan to "by-pass" the oil that is used to lubricate the engine. You wanted no more than 10% of the oil capacity to be bled off and filtered in the by-pass unit.

Does that mean that those units have 3 oil lines? One from oil pump to filter, another from oil filter to engine oil system, and another from filter to bypass engine to oilpan? Or does the filtered oil go back to the pan and then get pumped to the engine, un-re-filtered? Did the engine have the original factory filter, in addition to the ones you sold?

Try this, if you have filter with a flow rate of 3 gpm at .8 psi restiction and a filter with a flow of 1.5 gpm with a restriction of 1.6 psi you can get 3 gallons thru one and 1.5 gallons thru the other. But if you put both outputs thru a 2 gpm restriction you have almost all the oil flowing thru the 3 gpm filter with .8 restriction, and builds against the 2 gpm and backs up against the 1.5 gpm which will have almost no flow.quote:

Originally posted by edwardh1:

Purolater says:

PureOne filters meet the flow requirements of automotive applications. We

test our filters per SAE specification HS806 Chapter 1, and the standard

flow rate requirement that we follow states that the pressure differential

(between inlet and outlet) shall not exceed 3.0 psi at a flow rate of 3.0

gpm. On the PL30001 filters, flow restriction is 0.8 psi (avg) at 3.0 gpm.

I think.

Posted above

Why aren't we using an SAE test rather than a lets make up out own?????

I agree.

what are the SAE test specs and conditions? thats what the test(s) should be

Why aren't we using an SAE test rather than a lets make up out own?????

I agree.

what are the SAE test specs and conditions? thats what the test(s) should be

I have tested several Euro filters and I have measured also the pressure needed to open the bypass valve.

Here is the table:

I saw about 5 PSI pressure drop on most of the filters, so I think their bypass filters are still securely closed.

Please somebody check my calculations, the force in Newtons to open the valve is 100% right. The shape of the valve itself is a 2D circle, not a ball.

Here is the table:

I saw about 5 PSI pressure drop on most of the filters, so I think their bypass filters are still securely closed.

Please somebody check my calculations, the force in Newtons to open the valve is 100% right. The shape of the valve itself is a 2D circle, not a ball.

LOL, probably because this is someone's garage not a lab? They are trying to be helpful, but unless everyone here donated $100 at one time it seems unlikly they'll ever get the funds together to build the equipment to do some "SAE test specs and conditions".quote:

Originally posted by edwardh1:

Posted above

Why aren't we using an SAE test rather than a lets make up out own?????

I agree.

what are the SAE test specs and conditions? thats what the test(s) should be

SAE probably sells the specification like ANSI does and many other national organizations. with some of us involved with the industry seems someone would have access to it.

I think we are shooting in the dark with out own homemade testing.

seems the "society of sutomotive engineers" SAE would have answered "how to test filter drop " 20 years ago.

I think we are shooting in the dark with out own homemade testing.

seems the "society of sutomotive engineers" SAE would have answered "how to test filter drop " 20 years ago.

- Joined

- Sep 28, 2002

- Messages

- 39,798

Let's make sure that we're on the same page here. I can understand the confusion. A bypass filter has no bypass valve. A bypass filter may or may not be used in the manner that assigned it its name. It may or may not "bypass" the engine in doing its task. The common nomenclature has assigned it the "name" bypass filter and encompasses any high density fine filtration media device. A ff filter has a "bypass valve" incorporated that will bypass the filter media to limit the PSID across the ff media. If plumbed in parallel to a bypass (style) filter ..the bypass valve of the ff filter ..will also limit the PSID across the BYPASS FILTER to that same PSID.quote:

Since it is a bypass filter it will go into by-pass mode if the oil pressure is greater than 8-12psi on the high side. That would mean that the spring restrictor would have to open with less pressure than the by-pass of the bypass filter.

You're assuming that the biasing valve will create a differential all by itself. The FLOW will be 100% regardless of however it's configured assuming that the relief settings in the oil pump are not reached. 100% of the flow should generate the same (within certain variances, I'm sure) downstream pressure. The biasing valve is just assuring that the oil flow is compelled to the bypass filter ..and not just going to the ff filter (which is the only one with a bypass valve) by natural flow division via resistance to flow.

The bypass filter has a much denser media. The resistance it presents is more of an impendence. That is, it's not linear and changes as a result of viscosity of the transmitted fluid. Since 100% of the flow is going to go trough both filters ..the impedence that they both present will not ever be proportional. So a setup that would have a 10/90 spit ..under higher viscosity ...may turn into 1/99 until the oil thins. The biasing valve is to artificially (read-simulate) create a resistance in the ff to the flow.

Orifices don't work that way. They aren't proportional ...but if you had two filters rated at a given flow ..at a given visc ..and the same PSID ...then the flow would divide proportionally to their given flows. That is, two filters in parallel ..one rated at 2 gpm @ 4 PSID and one rated at 4 gpm @ 4 PSID...at 6 gpm of flow (assuming they were both rated at the same visc for the spec) and @ 4PSID ..the flow would probably be divided 2 gpm to one ..and 4 to the other.quote:

Try this, if you have filter with a flow rate of 3 gpm at .8 psi restiction and a filter with a flow of 1.5 gpm with a restriction of 1.6 psi you can get 3 gallons thru one and 1.5 gallons thru the other. But if you put both outputs thru a 2 gpm restriction you have almost all the oil flowing thru the 3 gpm filter with .8 restriction, and builds against the 2 gpm and backs up against the 1.5 gpm which will have almost no flow.

You've got to view oil flow along the line of the flow being the dictating constant (at whatever variable rate that may be at the time) and all other things being subordinant to it. Unless the oil pump reaches its relief limit ..100% of the flow is ...100% of the flow (it is what it is

[QB]

And I thought that a filter with a bypass valve in it was a bypass filter and that a fullflow filter had no bypass and all the oil had to go thru the filter so the full flow has to go thru the filter.quote:

Let's make sure that we're on the same page here. I can understand the confusion. A bypass filter has no bypass valve. ... A ff filter has a "bypass valve" incorporated that will bypass the filter media to limit the PSID across the ff media.

quote:

Originally posted by Gary Allan:

You've got to view oil flow along the line of the flow being the dictating constant (at whatever variable rate that may be at the time) and all other things being subordinant to it. Unless the oil pump reaches its relief limit ..100% of the flow is ...100% of the flow (it is what it is) . So 6gpm is going to flow no matter what and the pressures and velocities will change to satisfy the equation that you're working on in your head at the moment. Once you've determined the pressure relief limit of the oil pump ..the rest has to work it self out in the other variables one way or another. That is where you assume wrong. The pump is going to pump all it is allowed to pump because the motor only allows so much oil to pass thru the oil channels. Higher pressure will push more oil thru the same channels. It is the channels that determine the amount of oil flow. That is your 100%. You can't get more oil going thru the pump and filter than what goes into the engine. The pump pushing the oil against the oil gallery, oil passages, or oil channels (what ever you want to call them) is what gives you your oil pressure.

That is where you assume wrong. The pump is going to pump all it is allowed to pump because the motor only allows so much oil to pass thru the oil channels. Higher pressure will push more oil thru the same channels. It is the channels that determine the amount of oil flow. That is your 100%. You can't get more oil going thru the pump and filter than what goes into the engine. The pump pushing the oil against the oil gallery, oil passages, or oil channels (what ever you want to call them) is what gives you your oil pressure.

What is PSID? PSI is per square inch but what is the D?

differential?

- Status

- Not open for further replies.

Similar threads

- Replies

- 31

- Views

- 2K

- Replies

- 43

- Views

- 2K