Let me see if I can explain this in another way...

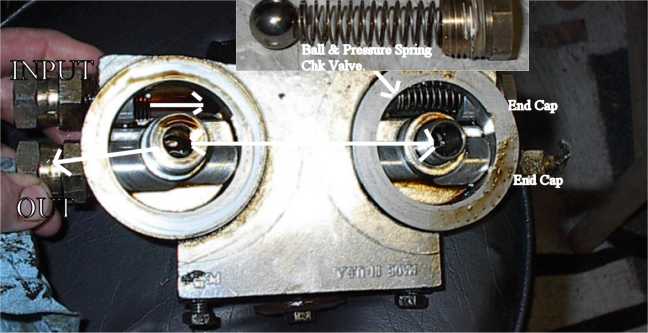

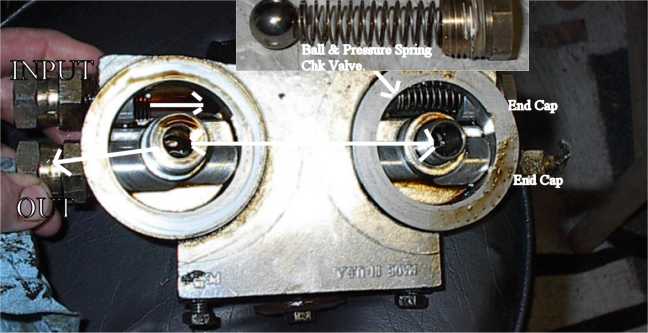

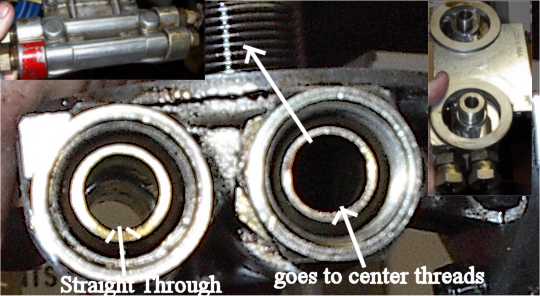

First the picture..

ok, as you look at it, there are only two channels. First, I blew air through the input side and when blocking off the first hole, it stop allowing air to flow until I removed the ball and check valve. Ok, now, once the restriction was removed, it was free flowing.

I then applied air through the output and covered each of the center threaded holes and both were unrestricted. Once both were covered there was no flow.

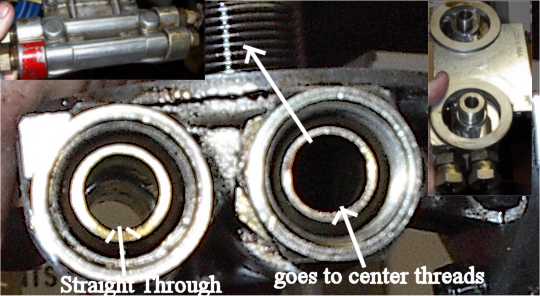

Now that I had established air flow through this part, I also took pictures so you could see where on the left side(input) there was a clear shot directly through the line.

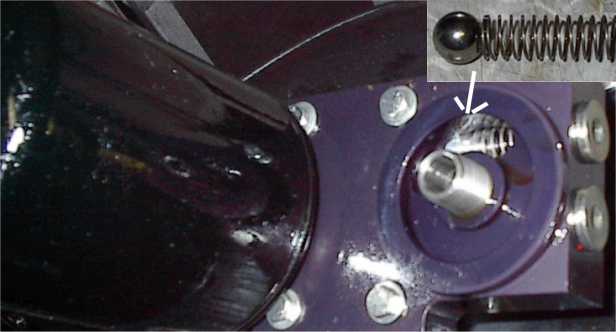

Ok, hoses, let's see how to explain the hoses,.... What is a function of a hose?. it is a way for a fluid(in this case) to travel through. Are there hoses (rubber not metal)that are design to cause a restriction of flow?. Well, in this case, both hoses are completely clear of all obstacles, and neither had any restriction. So, even if the hoses were reversed, how would that affect the flow?... ok, went out and took pics on the head and hoses. First, notice the hose numbers here.. Both the same...

Here is the head assembly where this matches up to the oil filter plumbing on the engine.

Notice, nothing but straight through, no restrictions.

Ok, now let's think about how this works...

Bypass filter is the filter on this block, unrestricted from flow direct from the oil pump. The pressure valve is between the bypass filter and the full flow filter. Now, something I failed to mention earlier, we also ran this setup with our gutted out fram and the psi was the same. So, conclusion, the full flow was not getting flow and that the 13psi is coming from the bypass filter only.

Here is the problem with this setup, the oil pump has a pressure relief valve similar to the pressure valve in the bypass system shown. Now, what is the pressure that it takes to over come the pressure to go into the full flow filter? Is it higher or lower than the pressure over flow valve located in the oil pump?. Why couldn't we overcome the valve with 40lbs of oil pressure against either one of them?

I also verified that the bypass filter is the filter closest to the input/output lines.