Quote:

My opinion is that straight weight oils are viable only in engines that get lots of continuous hours...

Trying to figure out lubrication based on imagining what's going on in an engine is what's got so many people misled about what's going on. This is a science and engineering subject and must be approached using the tools of those trades: testing and modeling.

Case in point: wear rates are highest during less than full operating temps. It's been proven through testing so many times. The fatal error that gets committed is attributing this to the oil being too thick. That's an imagination.

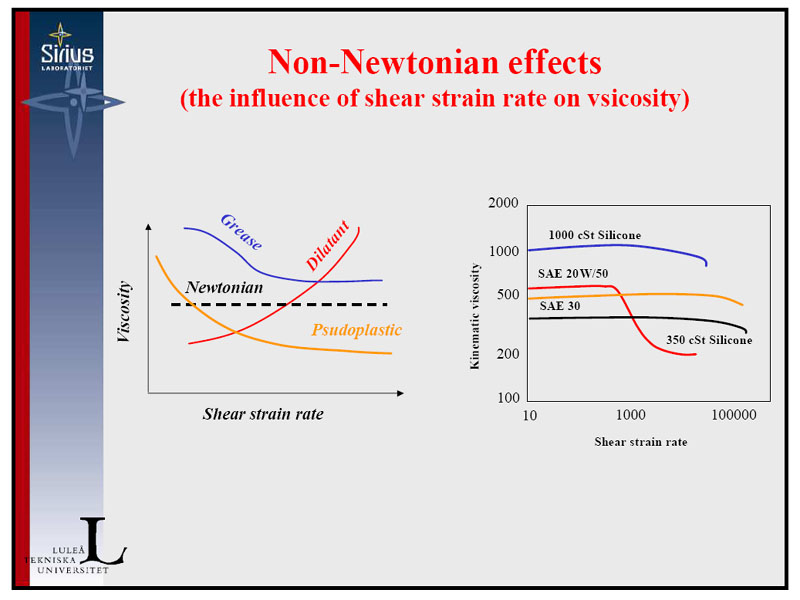

Case in point: fatal error of thinking that kinematic viscosity is the viscometric quantity that provides engine protection. Nope, kinematic viscosity is the viscosity at nearly zero shear rate, at atmospheric pressure, and some temperature. Those conditions are not present in bearings and cylinder walls where shear rates and pressures differ dramatically from those in the kinematic viscosity test.

Kinematic viscosity also can't predict cold cranking and cold pumping viscosities, for similar reasons.