2003 Protege 5

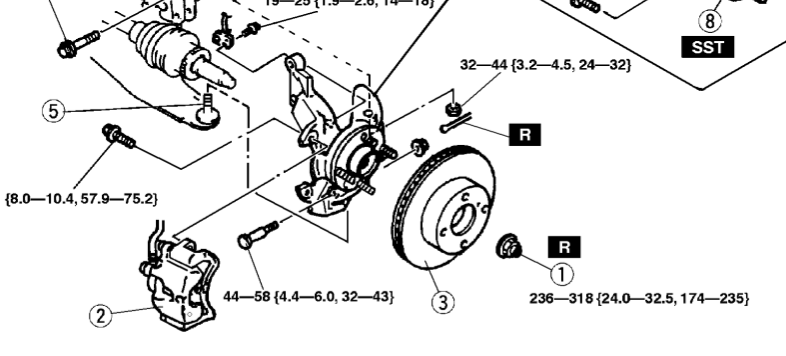

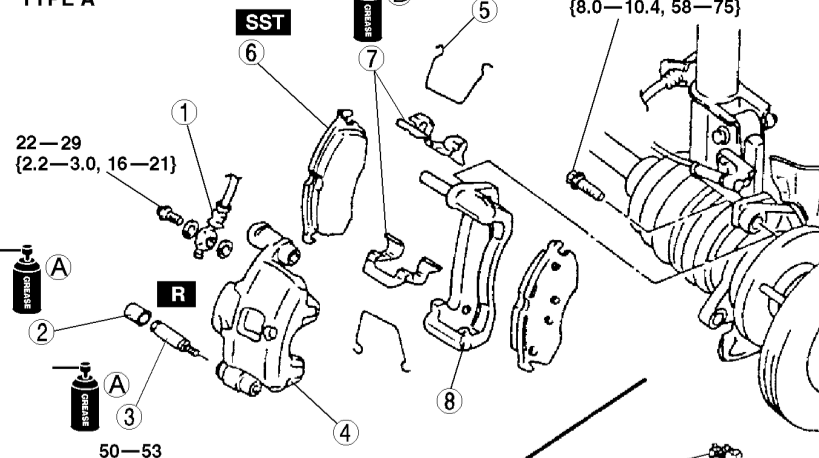

So replaced my steering knuckle since it was bent and throwing alignment off. Got new caliper bolts and the top one tightened fine. However, the bottom one kept spinning when trying to get it to spec torque. Pulled off the caliper/bolt to check it. Bolt is not stripped and when I look inside the caliper hole, it does not look stripped. When I try threading the bolts with the caliper off, the bottom and top bolts look like they bottom out at the same point and stop.

Any suggestions?

Thanks!

So replaced my steering knuckle since it was bent and throwing alignment off. Got new caliper bolts and the top one tightened fine. However, the bottom one kept spinning when trying to get it to spec torque. Pulled off the caliper/bolt to check it. Bolt is not stripped and when I look inside the caliper hole, it does not look stripped. When I try threading the bolts with the caliper off, the bottom and top bolts look like they bottom out at the same point and stop.

Any suggestions?

Thanks!