They’re available with Tier 4 or EU Stage IIIA emissions.I thought CAT was strictly off road emissions these days. (And .gov seems to want onroad for everything)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why haven’t we seen many diesel PHEVs?

- Thread starter SubieRubyRoo

- Start date

Brutally simple. Nobody buys them. Just ask Mazda. Plus diesels are way too expensive to build and get approved for the NA market

You can argue the efficiency factors all day. The most recent apples-to-apples comparison is way back in 2019 when the Skyactiv Mazda CX-5 offered equal highway fuel economy and about 10% less fuel economy in the city cycle according to the EPA.

The real world difference was about 20%. So let's use reality instead of EPA testing. What do you really get in return?

- Diesel costs that are usually far higher. (30% to 50% has been the norm until recently)

- A heaping load of environmental equipment that adds substantial cost to the customer.

- Repair issues that can be so expensive and difficult, that many diesel owners just completely remove the emissions equipment.

- A heavier vehicle due to engine weight,, which goes completely against the idea of having a hybrid vehicle.

Diesel = polluter in the minds of the car buying public. But even if that wasn't the case, there really is no intelligent reason to use a diesel engine in a hybrid instead of a gas engine unless we're talking about supercold climates. In which case a hybrid battery would be pointless.

For a little context, here's a great article that I googled after writing this.

You can argue the efficiency factors all day. The most recent apples-to-apples comparison is way back in 2019 when the Skyactiv Mazda CX-5 offered equal highway fuel economy and about 10% less fuel economy in the city cycle according to the EPA.

The real world difference was about 20%. So let's use reality instead of EPA testing. What do you really get in return?

- Diesel costs that are usually far higher. (30% to 50% has been the norm until recently)

- A heaping load of environmental equipment that adds substantial cost to the customer.

- Repair issues that can be so expensive and difficult, that many diesel owners just completely remove the emissions equipment.

- A heavier vehicle due to engine weight,, which goes completely against the idea of having a hybrid vehicle.

Diesel = polluter in the minds of the car buying public. But even if that wasn't the case, there really is no intelligent reason to use a diesel engine in a hybrid instead of a gas engine unless we're talking about supercold climates. In which case a hybrid battery would be pointless.

For a little context, here's a great article that I googled after writing this.

Last edited:

Brutally simple. Nobody buys them. Just ask Mazda. Plus diesels are way too expensive to build and get approved for the NA market

You can argue the efficiency factors all day. The most recent apples-to-apples comparison is way back in 2019 when the Skyactiv Mazda CX-5 offered equal highway fuel economy and about 10% less fuel economy in the city cycle according to the EPA.

The real world difference was about 20%. So let's use reality instead of EPA testing. What do you really get in return?

- Diesel costs that are usually far higher. (30% to 50% has been the norm until recently)

- A heaping load of environmental equipment that adds substantial cost to the customer.

- Repair issues that can be so expensive and difficult, that many diesel owners just completely remove the emissions equipment.

- A heavier vehicle due to engine weight,, which goes completely against the idea of having a hybrid vehicle.

Diesel = polluter in the minds of the car buying public. But even if that wasn't the case, there really is no intelligent reason to use a diesel engine in a hybrid instead of a gas engine unless we're talking about supercold climates. In which case a hybrid battery would be pointless.

For a little context, here's a great article that I googled after writing this.

Your context is accurate for a full power Hybrid with a normally sized engine

But what about the 660cc BMW I3 REX?

What about the large v8 end of the market?

There are use cases where the diesel is still much more efficient (1 liter and smaller) 5 liter and larger.

The BMW I3 as an example despite having coast down values a tad better than a Prius was a 32mpg- 42mpg rig using what was originally a 35hp engine.

The BSFC of the REX was about twice that of a comparable 1 liter naturally aspirated diesel in most power ranges.

The weight difference at that displacement is under 100 lbs all in.

Daihatsu 1 liter diesels are about as expensive as their gas counterparts.

In a Rex application diesel has a much better shelf life and the motors handle long durations of non-use better than a gas engine.

The reasons diesel can’t work are manmade and would be easily overcome but as you state, nobody would buy one.

So, I did some research and still can’t find any info this is even being tried in the way I see it in my head. MB makes a diesel hybrid, and there are two other cars with diesels but they put diesel driving one set of wheels and EV driving the other (link will be at the bottom).

But, why have we not seen a full EV powertrain with essentially just a diesel generator to extend the range? Meaning, the diesel would not be connected at all to propulsion, it would just generate power. This way, you could have a small turbodiesel that runs at a constant speed, so efficiency & BSFC could be maximized, and the genset could be tailored as well and could likely even provide 100% of the needed energy if the car was in the city.

It could be programmed to either come on at a given battery % like if the battery is nearly dead, or it could also be programmed to start up and run on a time-based schedule to top-up the battery, or even prevent starting if the battery was above say 75%. This would not only maximize range, it would always keep the driving experience 100% EV since you’re never coupling drive systems.

Plus, since you could probably achieve all of this with example: Kohler 3-cyl turbodiesel, sound deadening & NVH controls would be simple since it would operate at same speed all the time. These are already Tier IV compliant, so even greenies don’t have much to complain about.

Anybody read/heard anything why this approach hasn’t been tried? Seems like you could take one of the existing EVs that drives only one end, slap the Kohler/genset and a 5-10 gallon tank in the other end, and have an EV that could easily exceed 1000 miles between the need to plug it in OR refuel it??

https://www.greencarreports.com/new...why-they-dont-make-as-much-sense-as-you-think

https://kohlerpower.com/en/engines/product/kdi1903tcr

Emissions at least that was the unofficial reason BMW gave then the i8 wasn't launched with the intended 3-cyl diesel.

i3 is a piece of garbage, which is why nobody buys them anymore and they discontinued the model.Your context is accurate for a full power Hybrid with a normally sized engine

But what about the 660cc BMW I3 REX?

What about the large v8 end of the market?

There are use cases where the diesel is still much more efficient (1 liter and smaller) 5 liter and larger.

The BMW I3 as an example despite having coast down values a tad better than a Prius was a 32mpg- 42mpg rig using what was originally a 35hp engine.

The BSFC of the REX was about twice that of a comparable 1 liter naturally aspirated diesel in most power ranges.

The weight difference at that displacement is under 100 lbs all in.

Daihatsu 1 liter diesels are about as expensive as their gas counterparts.

In a Rex application diesel has a much better shelf life and the motors handle long durations of non-use better than a gas engine.

The reasons diesel can’t work are manmade and would be easily overcome but as you state, nobody would buy one.

Diesel is / was popular in many countries due to lower tax than gasoline, because they are used by commercial vehicles so they cannot tax them like passenger car for individuals (considered not a necessity in many part of the world).

Diesel in theory is more powerful so you can use a smaller engine for the same torque need, with a wider torque band so you don't need as many "speed" in the transmission. Hybrid with CVT like Prius eliminates a lot of the advantage diesel has over regular gas engine, and stop start makes it worse for diesel in low speed traffic (long distance driving at high speed would not benefit as much from a hybrid so a diesel engine is still beneficial).

i3 is a piece of garbage, which is why nobody buys them anymore and they discontinued the model.

Diesel is / was popular in many countries due to lower tax than gasoline, because they are used by commercial vehicles so they cannot tax them like passenger car for individuals (considered not a necessity in many part of the world).

Diesel in theory is more powerful so you can use a smaller engine for the same torque need, with a wider torque band so you don't need as many "speed" in the transmission. Hybrid with CVT like Prius eliminates a lot of the advantage diesel has over regular gas engine, and stop start makes it worse for diesel in low speed traffic (long distance driving at high speed would not benefit as much from a hybrid so a diesel engine is still beneficial).

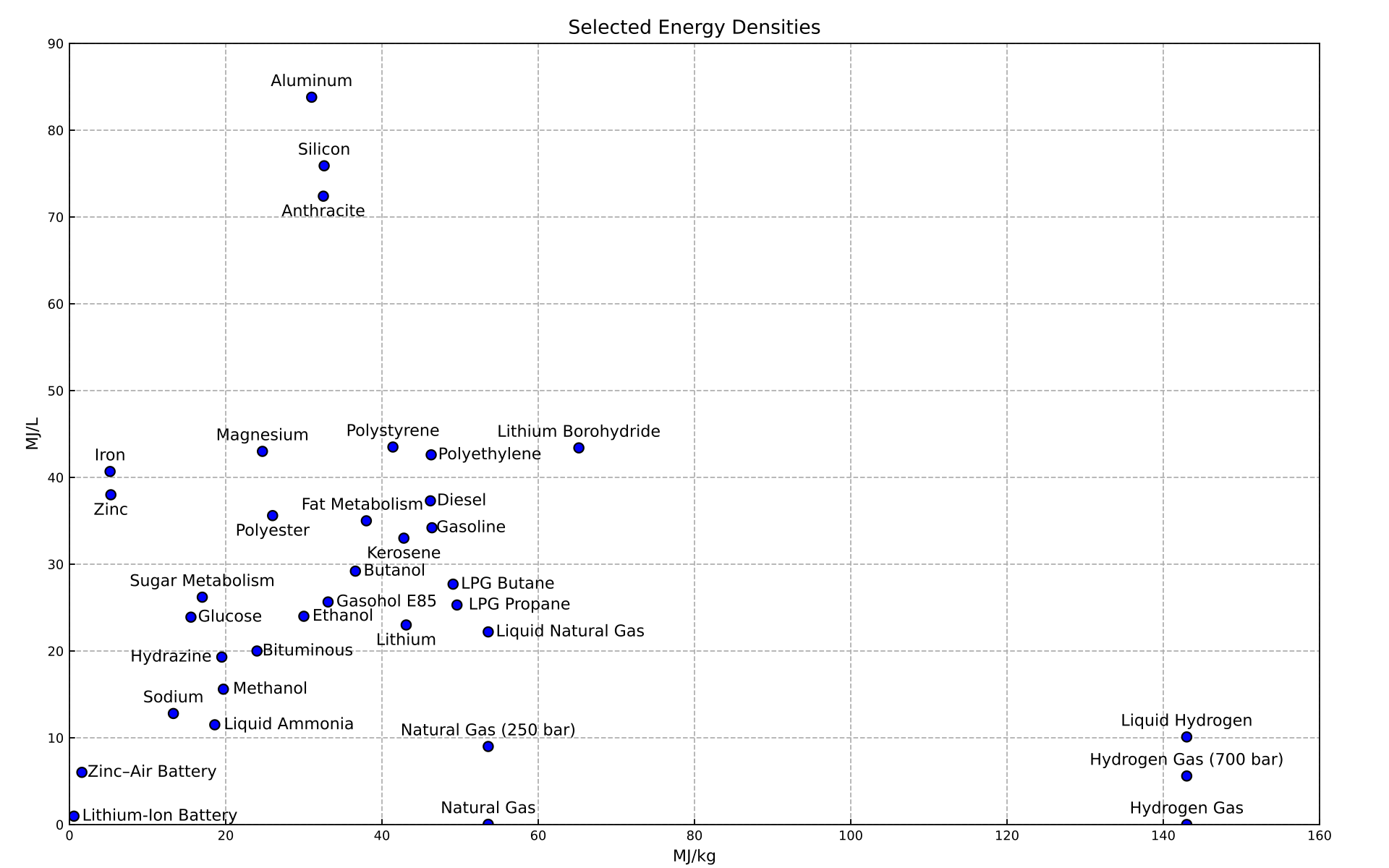

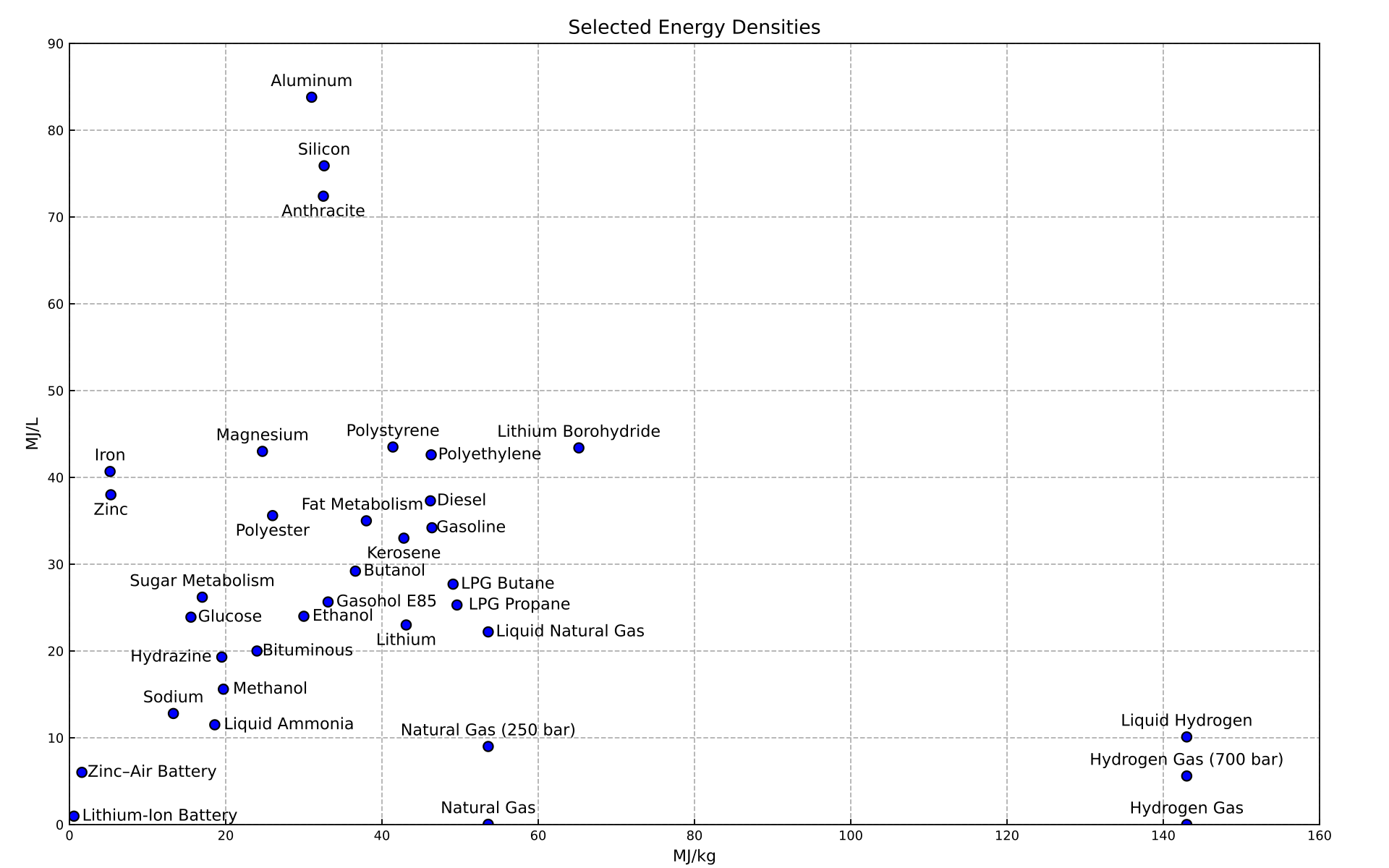

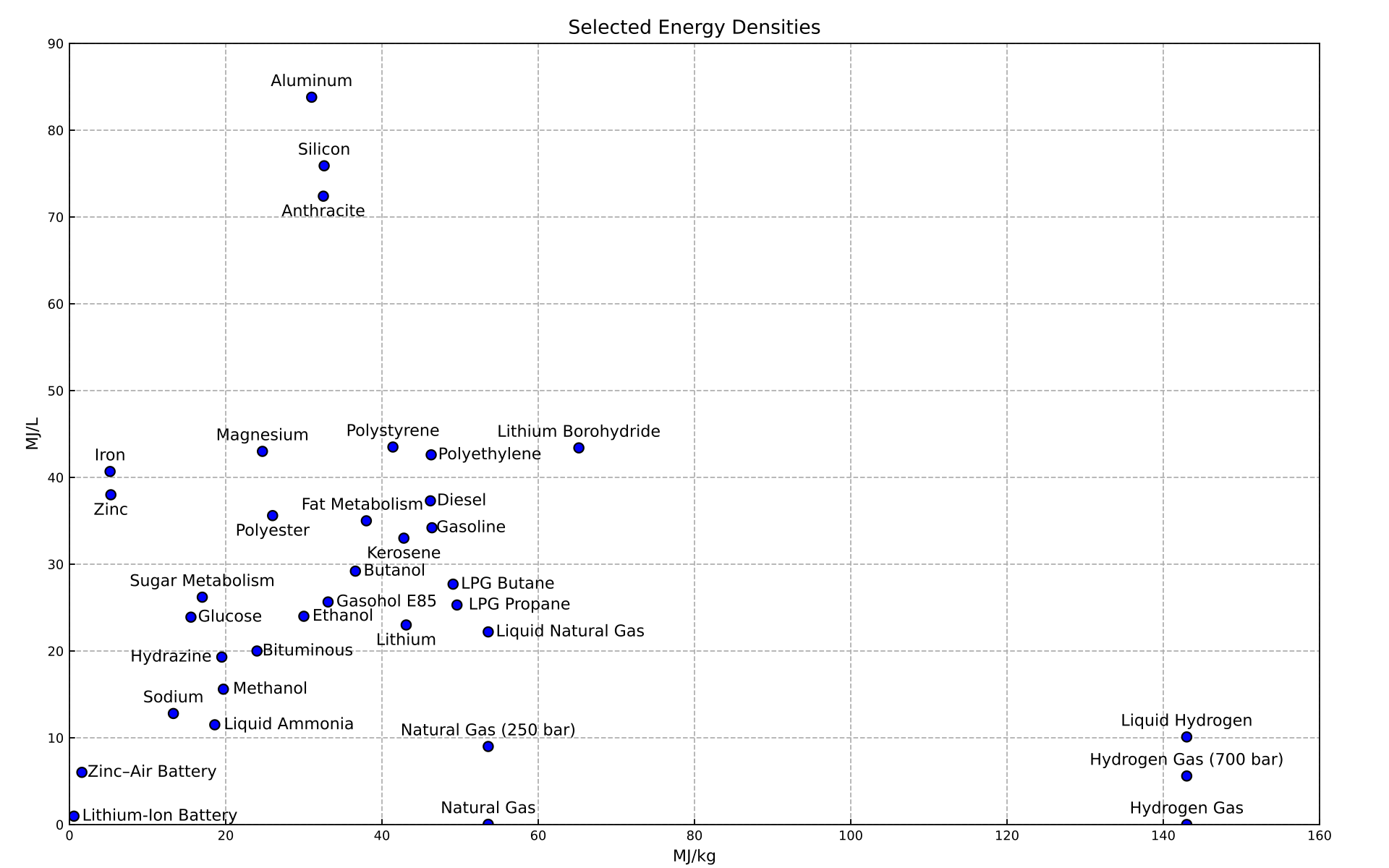

Part of the deal is that diesel is actually more energy dense than gasoline. On average there's maybe about 17-18% more energy per unit volume of diesel vs gasoline. There are a lot of variables of course.

I believe a lot of newer diesel cars require the use of diesel exhaust fluid, which might be a pain to deal with.

I've ridden on plenty of diesel-hybrid buses. I think the main systems are from Cummins and from Allison. They were extremely quiet coming from a stop where it was electric only. It looks like Cummins has a newer system that more like the OP's suggestion.

https://www.cummins.com/engines/b67-hybrid-2017

As for the original post, the proposal is obviously similar to how diesel-electric locomotives work, where that eliminates the need for a transmission. There are also some diesel-electric locomotives that can operate with a third rail for indoor use. Amtrak runs those at New York Penn Station. But I'd think a replacement locomotive these days might just implement a battery pack for that short distance to when it leaves the tunnel.

Third rail takes care of a lot of wear items for rather simple contact points for power. Railroads of all kinds got bashed in the news a while back for Precision Scheduled Railroad practices. What PSR boils down to be is differed maintenance. While we want an EV car to go a few hundred thousand miles on a battery, these locomotives need to go a few million minimum. They won’t take engines out of service to replace the starting batteries these days, “just don’t let it shut down” they say. If a hybrid locomotive battery went bad and they used a smaller generator and relied on the hybrid system for large power demand it would just be tagged “reduced power”. They’ll spend thousands to save pennies and all these massive train derailments is just one too many differed maintenance items.Part of the deal is that diesel is actually more energy dense than gasoline. On average there's maybe about 17-18% more energy per unit volume of diesel vs gasoline. There are a lot of variables of course.

I believe a lot of newer diesel cars require the use of diesel exhaust fluid, which might be a pain to deal with.

I've ridden on plenty of diesel-hybrid buses. I think the main systems are from Cummins and from Allison. They were extremely quiet coming from a stop where it was electric only. It looks like Cummins has a newer system that more like the OP's suggestion.

https://www.cummins.com/engines/b67-hybrid-2017

As for the original post, the proposal is obviously similar to how diesel-electric locomotives work, where that eliminates the need for a transmission. There are also some diesel-electric locomotives that can operate with a third rail for indoor use. Amtrak runs those at New York Penn Station. But I'd think a replacement locomotive these days might just implement a battery pack for that short distance to when it leaves the tunnel.

I love the idea, I really do. The one thing I’ve learned though in the railroad is that we’ll continue to use 30-40 year old equipment while they come out with a cool story about some new power supply that never makes it into the fleet because the story makes it look like they care about the environment. Amtrak could be different with battery power because they are basically just one big government program.

Third rail takes care of a lot of wear items for rather simple contact points for power. Railroads of all kinds got bashed in the news a while back for Precision Scheduled Railroad practices. What PSR boils down to be is differed maintenance. While we want an EV car to go a few hundred thousand miles on a battery, these locomotives need to go a few million minimum. They won’t take engines out of service to replace the starting batteries these days, “just don’t let it shut down” they say. If a hybrid locomotive battery went bad and they used a smaller generator and relied on the hybrid system for large power demand it would just be tagged “reduced power”. They’ll spend thousands to save pennies and all these massive train derailments is just one too many differed maintenance items.

I love the idea, I really do. The one thing I’ve learned though in the railroad is that we’ll continue to use 30-40 year old equipment while they come out with a cool story about some new power supply that never makes it into the fleet because the story makes it look like they care about the environment. Amtrak could be different with battery power because they are basically just one big government program.

I was was thinking of what they might need to do to replace the GE Genesis P32AC-DM. Obviously the GE Transportation successor is out of the passenger train business. I don't think the replacement (Siemens) for the standard Genesis locomotives have anything similar.

That Siemens one they bought has been a disaster too.I was was thinking of what they might need to do to replace the GE Genesis P32AC-DM. Obviously the GE Transportation successor is out of the passenger train business. I don't think the replacement (Siemens) for the standard Genesis locomotives have anything similar.

The SDi only met emissions regs because it was discontinued in most vehicle's before Euro 5 and 6 were introduced, the only vehicles it remained in were vans and perhaps an entry level Polo, I personally haven’t seen an SDi engined vehicle for sale in nearly 10 years, they were dog slow with around 70/80 bhp, almost nobody bought them because they were so slow and not much more economical than the more powerful turbocharged diesels.Turbo charged engines die rapidly in a hybrid.

Indirect hybrids (serial) loose 20% fuel economy on the highway. (Though the loss has slowly shrunk recently)

That is why they are rare.

For a diesel PHEV to make sense you would need to use a SDI (naturally aspired) diesel

SDI diesels are

1. Cheaper overall even including pollution controls than GDI (VWs last SDIs 2016 were cheaper than the turbo gasoline counterparts)

2. SDI emits less pollution and requires much more simplistic emissions controls than turbo

3. Restarts faster than a gas engine and is not damaged/ affected by repeated cold weather starts -15F

A range extender rarely needs to be more than 35hp in a PHEV, this means as little as a 1 liter 3 cylinder SDI could be used

The reason you don’t see the cheaper SDI used is because of the power to weight ratio.

Nobody will buy a vehicle that doesn’t have 1000hp on tap all the time.

Reality is that people’s perceived power requirements are destroying the environment in a variety of ways including more tire particles, more rare earths in oversized motors and worse efficiency.

Oddly enough SDI engines were one of the only VW engines that exceeded pollution standards and were not included in dieselgate.

As for indirect (trainlike) hybrids we do have them in the Nissan ePower and the BMW I3 rEx

Works great around the city but is inefficient on the highway, Honda solved this problem by adding 1 clutch providing a direct drive highway

The New Routemasters Bus as used in London is an Electric Bus with a small battery but a massive diesel generator that runs most of the time and isn’t connected to the wheels.

The E300de and older S300h are diesel hybrids but the electric motor doesn’t power the front wheels and the diesel motor the rears. They both use the 2.1 diesel engine and sound like a van.

A 35bhp diesel generator or range extender isn’t powerful enough to charge the batteries of anything bigger than a Milk Float

Diesel emissions are a pain to manage as is. Cold start emissions are an issue with all combustion engines. Add in the cost of the emissions equipment, reduced runtimes, etc - keeping it emissions compliant and durable would be a nightmare.

A Merc E300de will do 70/80 mpg fairly easily with little to no charging of the battery.

A BMW 530e will do 35/40mpg with the same treatment.

Both cars weigh around the same and are pretty much the same size, though 530e is XDrive, not sure if they even made a RWD 530e, I have never seen one.

Third rail takes care of a lot of wear items for rather simple contact points for power. Railroads of all kinds got bashed in the news a while back for Precision Scheduled Railroad practices. What PSR boils down to be is differed maintenance. While we want an EV car to go a few hundred thousand miles on a battery, these locomotives need to go a few million minimum. They won’t take engines out of service to replace the starting batteries these days, “just don’t let it shut down” they say. If a hybrid locomotive battery went bad and they used a smaller generator and relied on the hybrid system for large power demand it would just be tagged “reduced power”. They’ll spend thousands to save pennies and all these massive train derailments is just one too many differed maintenance items.

I love the idea, I really do. The one thing I’ve learned though in the railroad is that we’ll continue to use 30-40 year old equipment while they come out with a cool story about some new power supply that never makes it into the fleet because the story makes it look like they care about the environment. Amtrak could be different with battery power because they are basically just one big government program.

The battery idea works only if it can store enough energy to help downsize the engine. If train engine is already downsized to take a long time to accelerate to speed, and battery will never be big enough to regen braking the entire train efficiently and reliably, there really isn't a point to do battery on train for hybrid. Keeping battery at station for passenger trains may work, to help accelerate and decelerate, but then again if you already are tied to the grid why not just use the grid to buffer the entire train's energy? It is a bigger pool, way bigger, than any chemical battery anyways.

This really boils down to whether we want to electrify the train system or not. For passenger trains that need fast acceleration and deceleration there really is no reason not to be grid powered. For freight trains going long distance with few stops, and can tolerate slow acceleration, there really isn't much need to put in batteries. Just downsize the engine and let it accelerate slowly is good.

The battery idea works only if it can store enough energy to help downsize the engine. If train engine is already downsized to take a long time to accelerate to speed, and battery will never be big enough to regen braking the entire train efficiently and reliably, there really isn't a point to do battery on train for hybrid. Keeping battery at station for passenger trains may work, to help accelerate and decelerate, but then again if you already are tied to the grid why not just use the grid to buffer the entire train's energy? It is a bigger pool, way bigger, than any chemical battery anyways.

This really boils down to whether we want to electrify the train system or not. For passenger trains that need fast acceleration and deceleration there really is no reason not to be grid powered. For freight trains going long distance with few stops, and can tolerate slow acceleration, there really isn't much need to put in batteries. Just downsize the engine and let it accelerate slowly is good.

That's not how modern locomotives work. The workhorse is the diesel-electric locomotive, which is essentially just a constant engine speed diesel generator providing electricity for the electric motors and "head end" power (for the use of the train). I don't know exactly what they do with a train where the engine is off, but obviously they need to be able to start and perhaps provide power. But for the most part they idle for long stretches. The advantage to that setup is that they don't need a transmission and it's acceptable to accelerate slowly.

As far as I know, Amtrak's speed limit for diesel-electric is 79 MPH. Their electric lines are 120 MPH other than Acela which is a bit faster.

We already accelerate slowly. I wasn't making up when I said we may not hit track speed for 3 hours. We may never get there. We're talking 8,800 horsepower for as much as 22,000 tons. The math doesn't make sense, but somehow it moves. Just last week I stalled on a hill, had to cut away, and go get more power to pull it up the hill. Going with power storage for a true hybrid setup would be a nightmare for my job. The second it fails it would be the nail in the coffin. The stall last week cost an additional 3 hours and I never made it to my final destination. We had to be recrewed to get the train to the next point and I was on 14 hours on duty and only made it 160 miles.The battery idea works only if it can store enough energy to help downsize the engine. If train engine is already downsized to take a long time to accelerate to speed, and battery will never be big enough to regen braking the entire train efficiently and reliably, there really isn't a point to do battery on train for hybrid. Keeping battery at station for passenger trains may work, to help accelerate and decelerate, but then again if you already are tied to the grid why not just use the grid to buffer the entire train's energy? It is a bigger pool, way bigger, than any chemical battery anyways.

This really boils down to whether we want to electrify the train system or not. For passenger trains that need fast acceleration and deceleration there really is no reason not to be grid powered. For freight trains going long distance with few stops, and can tolerate slow acceleration, there really isn't much need to put in batteries. Just downsize the engine and let it accelerate slowly is good.

We use a lot of distributive power which helps a lot because of where the traction can help based on terrain that also allows less power to be used, but there is a line to that as well. Amtrak's limitations isn't on their power delivery, it's the freight used track they're on. I'm sure they could increase it if they weren't reliant on freight rail track.That's not how modern locomotives work. The workhorse is the diesel-electric locomotive, which is essentially just a constant engine speed diesel generator providing electricity for the electric motors and "head end" power (for the use of the train). I don't know exactly what they do with a train where the engine is off, but obviously they need to be able to start and perhaps provide power. But for the most part they idle for long stretches. The advantage to that setup is that they don't need a transmission and it's acceptable to accelerate slowly.

As far as I know, Amtrak's speed limit for diesel-electric is 79 MPH. Their electric lines are 120 MPH other than Acela which is a bit faster.

*edit*

Sorry, I missed your other comment there at first. There's a bank of batteries under the floor of the cab wired to supply 600V. That's what it takes to start the locomotive engine. On AC engines like the AC44 and any other variations which I may not be familiar with, it uses the DC generator which is what is used to generate power to the traction motors to turn the engine. This a huge generator so it's very slow to crank. It's a very weird sensation when they start because it spins at a fairly low RPM. It feels like an odd stutter until the engine smoothes out to a normal idle. DC locomotives use AC generators which are like a giant alternator. They can't be used as a starter, so they have a separate DC starter. They are much lighter and crank faster in comparison. They also have a 600V battery supply. I'll apologize up front that I don't have a huge breadth of knowledge on locomotives beyond my training. My understanding of their electronics is my wheelhouse since I spent many years in the electronics industry, but any true locomotive knowledge only comes from my engineer training a couple of years ago. The electronics side was easy to understand for me along with a big interest in the mechanical side being into how engines work, but I only know engine names of ones I've worked on because I really didn't have an outside interest in them. I'm familiar with the modern GE AC44 with my current railroad, though it's possible I've been on more that weren't marked otherwise. Before that I was on EMD GP38s, GP39s, SD40s, SD45s, and SD 60s. I do know that with EMD that GPs are 4 axle, and SDs are 6 axle. If you do have other interests in locomotives honestly you could probably teach me something. The only negative things I know of the Siemens Amtrak engines is from talking with previous colleagues that now work with Amtrak.

Last edited:

8800hp for 22000 tons is like a 0.8 hp engine moving a 2 ton car, going to be super slow acceleration, but once up to speed it doesn't take too much hp to stay moving. That 600V battery is like a starter battery for regular gasoline car, just enough to start engine and power some electronics but not enough to help with traction at all. The generator / electric motor is really just a simplified transmission like a CVT, not a hybrid like Prius or Accord where energy is stored and released when the engine output changes or when the vehicle speed changes.

I guess in a way we can think of freight train as a car with a golf cart engine and a CVT: very slow to start moving, CVT transmission, very efficient, and the driver is used to it taking a long time to accelerate, and it is ok to block other traffics. A small engine with CVT like that can be as efficient as a hybrid already, so I guess the freight engine is already very efficient and making any sort of hybrid won't make financial sense.

I guess in a way we can think of freight train as a car with a golf cart engine and a CVT: very slow to start moving, CVT transmission, very efficient, and the driver is used to it taking a long time to accelerate, and it is ok to block other traffics. A small engine with CVT like that can be as efficient as a hybrid already, so I guess the freight engine is already very efficient and making any sort of hybrid won't make financial sense.

Most trains will be 14,000-18,000 with that horsepower level, but I've seen as high as 24,000. I don't know how we didn't stall that day. The big takeaway is that they aren't looking for speed, just to get it there. With needing to meet other trains to pass and not making track speed it needs to get 200-250 miles in 12 hours time. If there's work to do picking up and setting out cars in between, I've had many times where we didn't make it.8800hp for 22000 tons is like a 0.8 hp engine moving a 2 ton car, going to be super slow acceleration, but once up to speed it doesn't take too much hp to stay moving. That 600V battery is like a starter battery for regular gasoline car, just enough to start engine and power some electronics but not enough to help with traction at all. The generator / electric motor is really just a simplified transmission like a CVT, not a hybrid like Prius or Accord where energy is stored and released when the engine output changes or when the vehicle speed changes.

I guess in a way we can think of freight train as a car with a golf cart engine and a CVT: very slow to start moving, CVT transmission, very efficient, and the driver is used to it taking a long time to accelerate, and it is ok to block other traffics. A small engine with CVT like that can be as efficient as a hybrid already, so I guess the freight engine is already very efficient and making any sort of hybrid won't make financial sense.

Just a reminder that Diesel fuel and conventional gasoline have exactly the same BTU content per pound (by mass).

The real difference is in engine efficiency. Small diesels are 44% thermally efficient and small gasoline engines are now 41% thermally efficient.

If we purchased fuel by weight or by energy content, the differences would be far less glaring.

The real difference is in engine efficiency. Small diesels are 44% thermally efficient and small gasoline engines are now 41% thermally efficient.

If we purchased fuel by weight or by energy content, the differences would be far less glaring.

Just a reminder that Diesel fuel and conventional gasoline have exactly the same BTU content per pound (by mass).

The real difference is in engine efficiency. Small diesels are 44% thermally efficient and small gasoline engines are now 41% thermally efficient.

If we purchased fuel by weight or by energy content, the differences would be far less glaring.

Fuel is still purchased by unit volume, where diesel typically has higher BTUs per gallon/liter.

We already accelerate slowly. I wasn't making up when I said we may not hit track speed for 3 hours. We may never get there. We're talking 8,800 horsepower for as much as 22,000 tons. The math doesn't make sense, but somehow it moves. Just last week I stalled on a hill, had to cut away, and go get more power to pull it up the hill. Going with power storage for a true hybrid setup would be a nightmare for my job. The second it fails it would be the nail in the coffin. The stall last week cost an additional 3 hours and I never made it to my final destination. We had to be recrewed to get the train to the next point and I was on 14 hours on duty and only made it 160 miles.

We use a lot of distributive power which helps a lot because of where the traction can help based on terrain that also allows less power to be used, but there is a line to that as well. Amtrak's limitations isn't on their power delivery, it's the freight used track they're on. I'm sure they could increase it if they weren't reliant on freight rail track.

*edit*

Sorry, I missed your other comment there at first. There's a bank of batteries under the floor of the cab wired to supply 600V. That's what it takes to start the locomotive engine. On AC engines like the AC44 and any other variations which I may not be familiar with, it uses the DC generator which is what is used to generate power to the traction motors to turn the engine. This a huge generator so it's very slow to crank. It's a very weird sensation when they start because it spins at a fairly low RPM. It feels like an odd stutter until the engine smoothes out to a normal idle. DC locomotives use AC generators which are like a giant alternator. They can't be used as a starter, so they have a separate DC starter. They are much lighter and crank faster in comparison. They also have a 600V battery supply. I'll apologize up front that I don't have a huge breadth of knowledge on locomotives beyond my training. My understanding of their electronics is my wheelhouse since I spent many years in the electronics industry, but any true locomotive knowledge only comes from my engineer training a couple of years ago. The electronics side was easy to understand for me along with a big interest in the mechanical side being into how engines work, but I only know engine names of ones I've worked on because I really didn't have an outside interest in them. I'm familiar with the modern GE AC44 with my current railroad, though it's possible I've been on more that weren't marked otherwise. Before that I was on EMD GP38s, GP39s, SD40s, SD45s, and SD 60s. I do know that with EMD that GPs are 4 axle, and SDs are 6 axle. If you do have other interests in locomotives honestly you could probably teach me something. The only negative things I know of the Siemens Amtrak engines is from talking with previous colleagues that now work with Amtrak.

I know nothing about the inner workings of locomotives. My professional electronics knowledge is pretty much just about 1s and 0s as well as RC and transport delay in integrated circuits.

I do remember getting up close and personal with a short excursion railroad. They had and still have a steam locomotive (which doesn't need a transmission since it won't stall) but I remember when it was being rebuilt they brought out a 50s era diesel-electric. I recall there was a big high-voltage warning on the side of the locomotive.

By Robert A. Estremo, CC BY-SA 2.5, https://commons.wikimedia.org/w/index.php?curid=16942610

Just on memory, I think that's an MP-15. I only knew them as switching units, but they were on their way out when I started. I haven't seen any in operation where I have worked, but I dealt with some while they were being decommissioned and sold to industries that needed more power than a standard car mover.I know nothing about the inner workings of locomotives. My professional electronics knowledge is pretty much just about 1s and 0s as well as RC and transport delay in integrated circuits.

I do remember getting up close and personal with a short excursion railroad. They had and still have a steam locomotive (which doesn't need a transmission since it won't stall) but I remember when it was being rebuilt they brought out a 50s era diesel-electric. I recall there was a big high-voltage warning on the side of the locomotive.

By Robert A. Estremo, CC BY-SA 2.5, https://commons.wikimedia.org/w/index.php?curid=16942610

Similar threads

- Replies

- 9

- Views

- 207

- Replies

- 5

- Views

- 864