Of course most of you know who I am and my limited background. Anyway, let me give you my ideas and PERSONAL OPINIONs on this subject.

First, many chemists/tribo's tell you that the synth base fluids will protect better, some even state better "film strength". Question is does synth based oils protect better... q1-AGAINST WEAR? or q2-AGAINST OIL BREAK DOWN?

My answer, q2, against oil break down, Not against wear.

Understand I'm talking about standard oil drains, not pushing extended. Extended drains is where synth stocks will prevail, no doubt but here's the catch, provided the additive package holds up and in many/most cases we see, most are changing filters and adding fresh additives with new top off oil to accomplish this as well.

Why do I say this... My argument to this is,

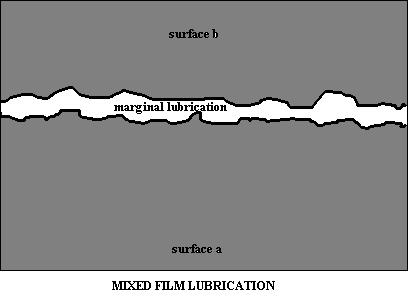

To protect against wear you must have a hydrodynamic layer of oil between the two surfaces to keep them from scuffing each other.

So, in an automotive application how is this done. The oil pump provides say 40-50lbs of oil pressure between the rod bearing and the crank. This pressure will provide that "wedge" of oil and provide enough oil between the parts. What happens if the oil pressure is only 25-30lbs at idle then you put a load on it during acceleration?, You then don't have that wedge effect, and so it can be squeezed out momentarily, thus the scuffing happens.

So, how does a synth base oil differ and keep it protected better? well, if flow resistance is pressure, and there is little flow, which creates less pressure, then when the force of the two objects(bearing/crank) squeeze together, and based on the fact that we've determined that oil flows at a certain rate and WILL take the least path of resistance, then that wedge or hydrodynamic film doesn't exist, thus the reason why anti scuffing/anti wear additives are used. One of the things I've noticed is that EVERY SYNTH OIL has an abundance of these additives. As Gman pointed out about M1, when the first came out with their first version of SS, it failed miserably on the timken, but soon afterwords, moly (among other additives) were introduced to assist the oil and now, it provides excellent resistance to hydrodynamic shearing on the timken compared to earlier comments. Point is, Hydrodynamic wedge effect must be present to create that barrier between the parts and under normal conditions, this does not happen except in hwy driving all the time.

So, to say that the synth base stock is going to provide better film strength, I personally believe

that we are referring to the molecular level as the CH chains are more resistant to oxidation in a synth and will not shear down thus losing it's viscosity as easily. This doesn't mean that it provides better hydrodynamic film strength as that is contingent to oil flow(min) and (max)pressure which is developed from the oil pump and engine bearings(clearences).

So, is the additive levels less in synth's? of course there are areas in synths that do not need as much if any additives when it comes to synth's but that's more based on viscosity improver's and cleaning additives all of which normally helps enhance the base oils longivity. When if comes to AW/FM'additives, I do believe that is one area that will not at this time be reduced based on reliance of the new synth base oil. The base oil will have to be able to develop a barrier level of sorts to allow for lessen amount of aw/fm additives to be reduced/ eliminated.

Another point is as much as many fail to see the timken as a valuable tool in seeing how an oil performs, I find that if an oil won't provide an effective barrier protection on this, it IMO lacks protection in load and shear in comparision to other oils. All mechanical equipment experience this shearing at certain times.

As of yet, I've not seen any oil that doesn't have AW/FM's in their oils, so a synth based oil or not, that last line of defense and is a very critical part of any oil thus you see an abundance of aw/fm's in synth's. Take out these additives from Amsoil's best oils(which they havev higher levels of zddp than api allowed) and you'll see, that's one of the biggest differences in wear protection with that oil, same with redline, take out all that moly and zddp, they use an excellent base stock, yet you notice the extreme load of the aw/fms.

If one of these chemists/tribo's has nothing but a base oil with no aw/fm's that would provide this exceptional level of wear protection under a shearing condition, I'd love to see it

If you remember watching my video on M1's SS when it first came out, I was not able to get it to provide ANY, not ONE ounce of protection on that machine yet all the other oils did. I had to finally just quit grinding on it. Now, understand this isn't to say that it can't happen and that they can't create a base oil to replace the aw/fm additives. As of yet,I've seen no evidence shown that a hydro dynamic film exists all the time under all situations and as of yet, I've not seen one synth oil worth using not have aw/fms, This includes the best of the best, LE,Schaeffers, Redline, Amsoil, etc...