You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Roller Coaster scare ... A Minor Crack!

- Thread starter TheLastWord

- Start date

My guess, Chinese steel (if it is in fact steel) . This stuff does not happen with quality steel. Steel bends, twists, buckles and generally withstands everything you can throw at it before cracking. And generally fatigue cracks in steel are not quite so simple looking on a complex part. They will often (but not always) have a very ragged look.

TheLastWord

Thread starter

Daily inspections!!

It was reported by a visitor.

Cameras in critical locations is a cheap but effective tool.

It was reported by a visitor.

Cameras in critical locations is a cheap but effective tool.

My guess, Chinese steel (if it is in fact steel) . This stuff does not happen with quality steel. Steel bends, twists, buckles and generally withstands everything you can throw at it before cracking. And generally fatigue cracks in steel are not quite so simple looking on a complex part. They will often (but not always) have a very ragged look.

As a counterpoint, the agency I work for employs a team dealing with fatigue cracking in high quality steel. Even more to the point, all the steel used in our structures has to meet "Made in America" requirements due to our funding sources. (To put two and two together, think about how many steel bridges you drive over daily - more of them have fatigue cracking than you'd suspect) As much as we'd like to press an "easy" button here, its a bit early.

FWIW, the coaster in this case is steel, and was fabricated by a firm in Ohio, with the engineering provided by the Swiss coaster design firm.

Thanks for the response. I noticed I missed inserting something. I had intended to say This stuff does not happen with "properly loaded" quality steel.As a counterpoint, the agency I work for employs a team dealing with fatigue cracking in high quality steel. Even more to the point, all the steel used in our structures has to meet "Made in America" requirements due to our funding sources. (To put two and two together, think about how many steel bridges you drive over daily - more of them have fatigue cracking than you'd suspect) As much as we'd like to press an "easy" button here, its a bit early.

FWIW, the coaster in this case is steel, and was fabricated by a firm in Ohio, with the engineering provided by the Swiss coaster design firm.

The George Washington Bridge is 96 years old and remains (mostly) intact, despite decades of severe neglect despite the extreme tolls

I vote for design flaw. Rodeo cowboys design for stress tolerance when everything is perfect.

Seldom is everything perfect. Maybe being the tallest and fastest, also needs the mostest margin for imperfection.

Seldom is everything perfect. Maybe being the tallest and fastest, also needs the mostest margin for imperfection.

Fat people causing more stress than the slimmer swiss people?!

Owen Lucas

$100 Site Donor 2023

- Joined

- Sep 5, 2021

- Messages

- 3,617

Not sure if this is fake or not, but looks like some plastic wrap was applied??!!

(image removed - rules violation; Mod)

(image removed - rules violation; Mod)

Last edited by a moderator:

Likely a weld issue that propagated. Very familiar with the ride and it doesn't matter that it's one of the biggest/tallest whatever, this particular company doesn't push G-forces like some others, regardless of ride size, so it's no worse than a much smaller ride in terms of forces on the structure. A ride 100ft tall can exceed the forces on a 400ft ride, and they do.

The manufacturer also have impeccable safety and reliability within the industry. Literally, top notch in the design/engineering (and you pay for it). The size of the ride has nothing to do with this failure... It's unlikely to be a design error. They know the forces on every foot of track during the design resulting from full trains, plus safety margins, and apply those loads to the structural design, footings, etc...

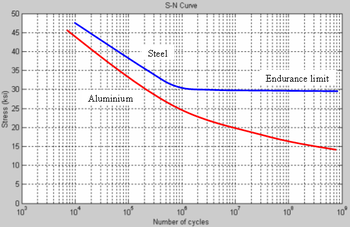

Rides require repair/weld all the time as general upkeep. This ride is now 8 years old, running hundreds of cycles per day in that time. Likely a flaw that was not detected and repaired early on that just fully failed in time. Rumors that maintenance budgets within the park chain have run maintenance crews thin, and perhaps, was missed on any visual inspection performed. This particular support column is right over entrance walkways into the park, very clearly seen and inspected (if it was).

Many rides, new and old, have required weld repairs and structural upkeep over time. It is not unusual, at all.

I contacted an old work friend, who worked maintenance at an amusement park I also worked at as a teenager... I asked about the inspections they performed on the steel coasters at that particular park. He confirmed in the spring, they would sub out the full structural visual inspection to a company. They would climb all over the structure looking for issues/defects before the state signed off for the season. Day-to-day, they did not do this level of inspection on the ride structure. More-so just on the ride vehicles, lift chain, booster wheels and other mechanical wear/tear items.

At the end of the day, I think this was likely just flawed weld that took eight years to fail, propagate and give out. But, this probably should have been found much sooner. There are rumors that this failure was seen on photos a week prior of the same column, but was not reported or noticed by park maintenance. But the source is not clear on that one.

That being said, given that the support is fully broke... The lack of structural sway on the track is impressive, likely due to the tall track spine (they vary the height to increase the moment of inertia on the track, for high stress areas). It moves, sure, but given that there is quite a span between the good supports... Thing looks solid.

It was placed after the fact to keep moisture/birds/whatever out of the column. It was not put there as any type of repair, obviously.

The manufacturer also have impeccable safety and reliability within the industry. Literally, top notch in the design/engineering (and you pay for it). The size of the ride has nothing to do with this failure... It's unlikely to be a design error. They know the forces on every foot of track during the design resulting from full trains, plus safety margins, and apply those loads to the structural design, footings, etc...

Rides require repair/weld all the time as general upkeep. This ride is now 8 years old, running hundreds of cycles per day in that time. Likely a flaw that was not detected and repaired early on that just fully failed in time. Rumors that maintenance budgets within the park chain have run maintenance crews thin, and perhaps, was missed on any visual inspection performed. This particular support column is right over entrance walkways into the park, very clearly seen and inspected (if it was).

Many rides, new and old, have required weld repairs and structural upkeep over time. It is not unusual, at all.

I contacted an old work friend, who worked maintenance at an amusement park I also worked at as a teenager... I asked about the inspections they performed on the steel coasters at that particular park. He confirmed in the spring, they would sub out the full structural visual inspection to a company. They would climb all over the structure looking for issues/defects before the state signed off for the season. Day-to-day, they did not do this level of inspection on the ride structure. More-so just on the ride vehicles, lift chain, booster wheels and other mechanical wear/tear items.

At the end of the day, I think this was likely just flawed weld that took eight years to fail, propagate and give out. But, this probably should have been found much sooner. There are rumors that this failure was seen on photos a week prior of the same column, but was not reported or noticed by park maintenance. But the source is not clear on that one.

That being said, given that the support is fully broke... The lack of structural sway on the track is impressive, likely due to the tall track spine (they vary the height to increase the moment of inertia on the track, for high stress areas). It moves, sure, but given that there is quite a span between the good supports... Thing looks solid.

Not sure if this is fake or not, but looks like some plastic wrap was applied??!!

(image removed - rules violation; Mod)

It was placed after the fact to keep moisture/birds/whatever out of the column. It was not put there as any type of repair, obviously.

This sounds like when I worked maintenance for a apartment complex a year and a half back. I have basic maintenance knowledge and can repair alot but more and more wanted me to repair hvac ie. A/C and furnaces. I told the company send me for training and pay what hvac workers get. They dropped the whole thing and said nevermind.Likely a weld issue that propagated. Very familiar with the ride and it doesn't matter that it's one of the biggest/tallest whatever, this particular company doesn't push G-forces like some others, regardless of ride size, so it's no worse than a much smaller ride in terms of forces on the structure. A ride 100ft tall can exceed the forces on a 400ft ride, and they do.

The manufacturer also have impeccable safety and reliability within the industry. Literally, top notch in the design/engineering (and you pay for it). The size of the ride has nothing to do with this failure... It's unlikely to be a design error. They know the forces on every foot of track during the design resulting from full trains, plus safety margins, and apply those loads to the structural design, footings, etc...

Rides require repair/weld all the time as general upkeep. This ride is now 8 years old, running hundreds of cycles per day in that time. Likely a flaw that was not detected and repaired early on that just fully failed in time. Rumors that maintenance budgets within the park chain have run maintenance crews thin, and perhaps, was missed on any visual inspection performed. This particular support column is right over entrance walkways into the park, very clearly seen and inspected (if it was).

Many rides, new and old, have required weld repairs and structural upkeep over time. It is not unusual, at all.

I contacted an old work friend, who worked maintenance at an amusement park I also worked at as a teenager... I asked about the inspections they performed on the steel coasters at that particular park. He confirmed in the spring, they would sub out the full structural visual inspection to a company. They would climb all over the structure looking for issues/defects before the state signed off for the season. Day-to-day, they did not do this level of inspection on the ride structure. More-so just on the ride vehicles, lift chain, booster wheels and other mechanical wear/tear items.

At the end of the day, I think this was likely just flawed weld that took eight years to fail, propagate and give out. But, this probably should have been found much sooner. There are rumors that this failure was seen on photos a week prior of the same column, but was not reported or noticed by park maintenance. But the source is not clear on that one.

That being said, given that the support is fully broke... The lack of structural sway on the track is impressive, likely due to the tall track spine (they vary the height to increase the moment of inertia on the track, for high stress areas). It moves, sure, but given that there is quite a span between the good supports... Thing looks solid.

It was placed after the fact to keep moisture/birds/whatever out of the column. It was not put there as any type of repair, obviously.

The only real way to know if a piece of steel is structurally good is to X-ray it. In this case the X-ray would need to have been done after joint was formed, so i presume not. I have only seen it done in instances where a single piece failure can cause a complete failure of the assembly. Since it didn't fall down its obviously a redundant design, so the design did its job.

It could be material failure or design failure - there are plenty examples of both. Unfortunately whatever they tell the public will be highly sanitized and we will likely never get to know.

It could be material failure or design failure - there are plenty examples of both. Unfortunately whatever they tell the public will be highly sanitized and we will likely never get to know.

35 years in engineering...you would not beleive how many things I've seen cracked, that sends me into shivers.

One of the clearest memories I have of a second year uni lecture was the statement that eary engineers thought that steel was infinitely rigid...and if it was, then EVERYTHING would fall down. Even the process of building such a structure needs parts to plastically...

While that looks spectacular, and I would never ride in that condition, the loads have been moved to some other part of the structure...some other part that may have well yielded to accomodate (the presence of the gap leads me to beleive that something somewhere else has plastically deformed).

One of the clearest memories I have of a second year uni lecture was the statement that eary engineers thought that steel was infinitely rigid...and if it was, then EVERYTHING would fall down. Even the process of building such a structure needs parts to plastically...

While that looks spectacular, and I would never ride in that condition, the loads have been moved to some other part of the structure...some other part that may have well yielded to accomodate (the presence of the gap leads me to beleive that something somewhere else has plastically deformed).

What most likely happened was that tubular structure was hastily welded together by the lowest bidder with no care for the heat affected zone around the weld. The standards for welds on those things are really relaxed. You can have tons of slag inclusions, undercut, and cold lap and still get a pass. They slapped some weld on it, no heat treatment, and undercut or cold lapped the weld, causing a stress point with brittle metal surrounding it. It was probably cracked underneath from the very beginning and took enough cycles and vibrations to send the crack on through the rest of the pipe.

Learning metallurgy and welding engineering, and the practices that are allowed in some industries, has made me very weary of amusement park rides (especially carnival rides) and elevators.

Learning metallurgy and welding engineering, and the practices that are allowed in some industries, has made me very weary of amusement park rides (especially carnival rides) and elevators.

Owen Lucas

$100 Site Donor 2023

- Joined

- Sep 5, 2021

- Messages

- 3,617

The transients that put them together are also a factor. I don't mean to be derogatory but it is not uncommon for migrants and offenders of various types to be assembling these rides. I am sure missing bolts are common and the wear and tear of these rides accumulating 100's of thousands of miles over the years and then being disassembled and reassembled across the country is significant. Hopefully there are inspections before these rides are opened up. I would never put any kids because there are too many unknowns.especially carnival rides

https://www.daily-journal.com/news/...cle_c3d65d80-3991-5612-ab14-ad7c255fdb28.html

Similar threads

- Replies

- 22

- Views

- 4K

- Replies

- 27

- Views

- 5K