Here's Gohkan's excellent thread on TGMO back in the day.

https://bobistheoilguy.com/forums/ubbthreads.php/topics/3356846/Toyota_TGMO_0W-20_SN_VOA_with_

Originally Posted By: Gokhan

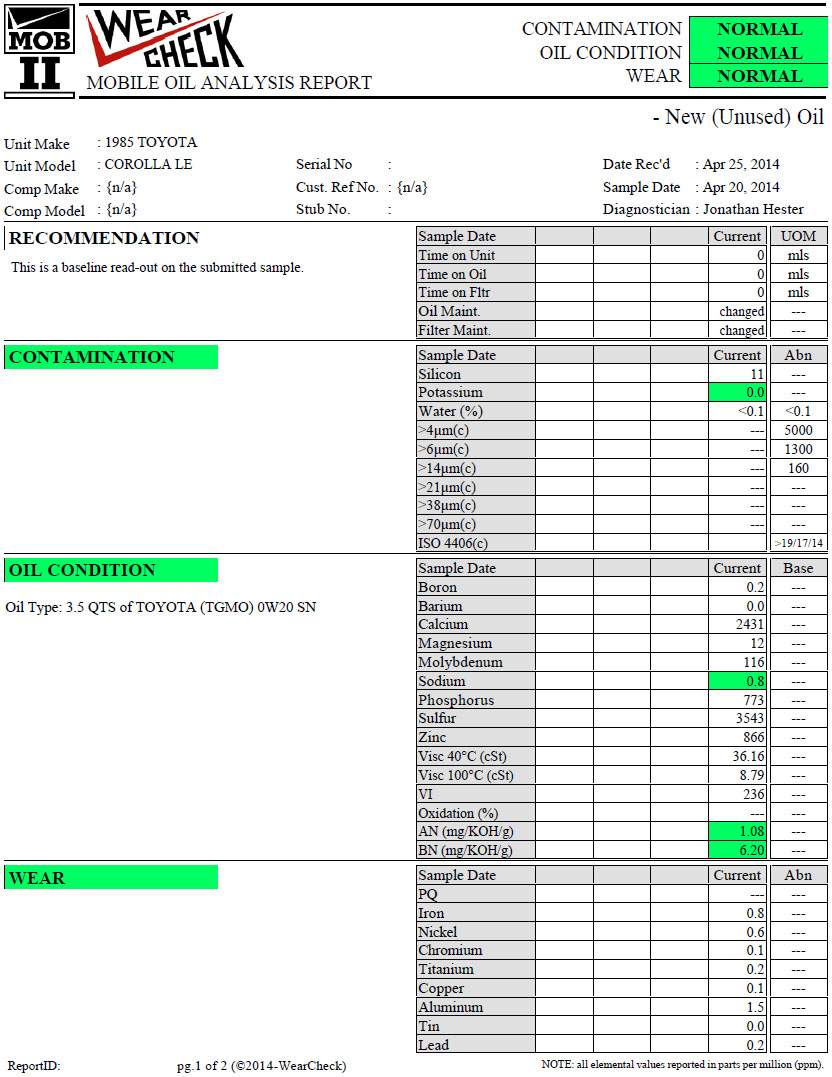

Consider this the official VOA of TGMO 0W-20 SN.

I just got the VOA results for the latest batch of Toyota TGMO 0W-20 SN/GF-5. The results are stunning for this top-ranked oil.

Viscosity index (VI) is a whopping 236, even shadowing JX Nippon Oil Eneos Sustina 0W-20 SN (VI 229) that boasts about its VI as its main selling point. This is showing that it's made of ExxonMobil's

Visom Group III+ base stocks and very high-quality viscosity-index improver (VII).

KV @ 100 C is a very high, 5W-30-ish 8.79 cSt, very close to the 5W-30/10W-30 range (9.3 cSt or higher). Therefore, with its high viscosity, it's suitable for xW-30 applications.

Oil shear is only 1.3% according to my

UOA. Therefore, it's an extremely shear-stable oil, showing that it's made of the highest quality viscosity-index improver (VII).

Additive package is extremely strong. ZDDP at 773 ppm P is near the 800 ppm maximum P limit. ExxonMobil/Shell (Infineum) trinuclear moly is at a very large 116 ppm.

There is a large dose (2431 ppm) of calcium detergent. There is no potentially harmful magnesium detergent (only 12 ppm).

TAN is very low at 1.08, showing that the concentration of potentially harmful succinimide dispersants is low.

Low TAN and low Mg contrasts with many of the newer oils like Mobil 1 SN, which have high Mg and high TAN that are potentially harmful to the engine.

TBN retention and TAN arrest is excellent according to my

UOA. TBN decreased only to 5.25 from 6.20 and TAN increased only to 3.33 from 1.08 in 5170 miles. However, the low-sulfur gasoline in California helps keep TBN high and TAN low as well.

The sample was taken from one of the latest batches of TGMO 0W-20 SN. I chose the bottles with the latest date-code stamp on the Toyota-dealer shelf. I shook the bottle very well before I poured the sample so that the additives would be fully mixed.

This is the summary:

Fe 0.8

Ni 0.6

Cr 0.1

Ti 0.2

Cu 0.1

Al 1.5

Sn 0.0

Pb 0.2

Si 11

K 0.0

B 0.2

Ba 0.0

Ca 2431

Mg 12

Mo 116

Na 0.8

P 773

S 3543

Zn 866

KV40 36.16

KV100 8.79

VI 236

TAN 1.08

TBN 6.20

This is a truly exceptional oil that has no match to its top ranks.