Originally Posted By: Gokhan

Originally Posted By: SR5

Thanks for that, yes Ester in back and white for M1. Very clear.

On a different note, I remember the old Magnatec formula has Ester in it's spec sheet as the component that bonded to the metal surface to resist drain back. The silly "intelligent molecule" name they gave it, or something like that. However I have since heard it no longer uses a ester, but some other chemical, I wonder what that is? It still seems to work very well given the quality of the UOA's coming out for Castrol Magnatec. Looks like castrol is heading in a different direction now days....many paths to the top of the mountain.

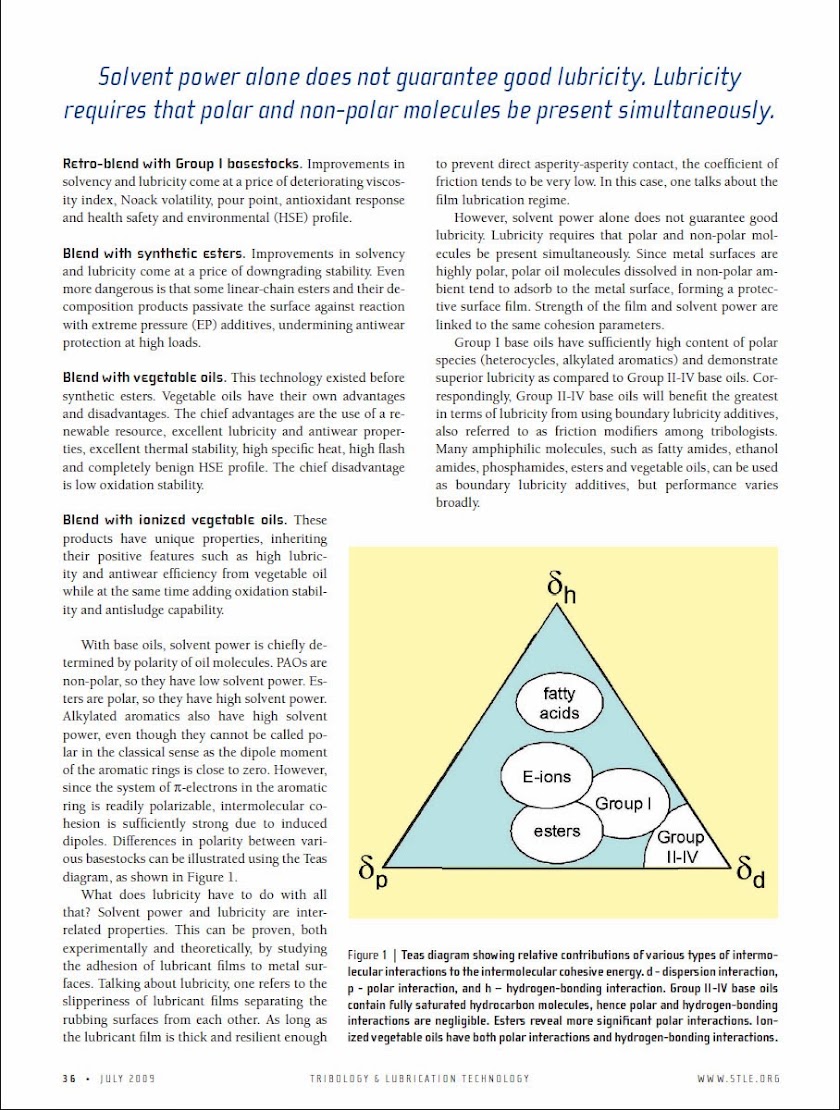

Sticking to surfaces is the "lubricity" property of an oil. Yes, synthetic esters and vegetable oils have good lubricity along with Group I conventional base stocks.

A long time ago I had posted the reference below about lubricity. Esters increase lubricity but they may interfere with EP agents such as moly, as they both compete for metal surfaces. They also have stability issues. See page 3:

The following is an excellent article (

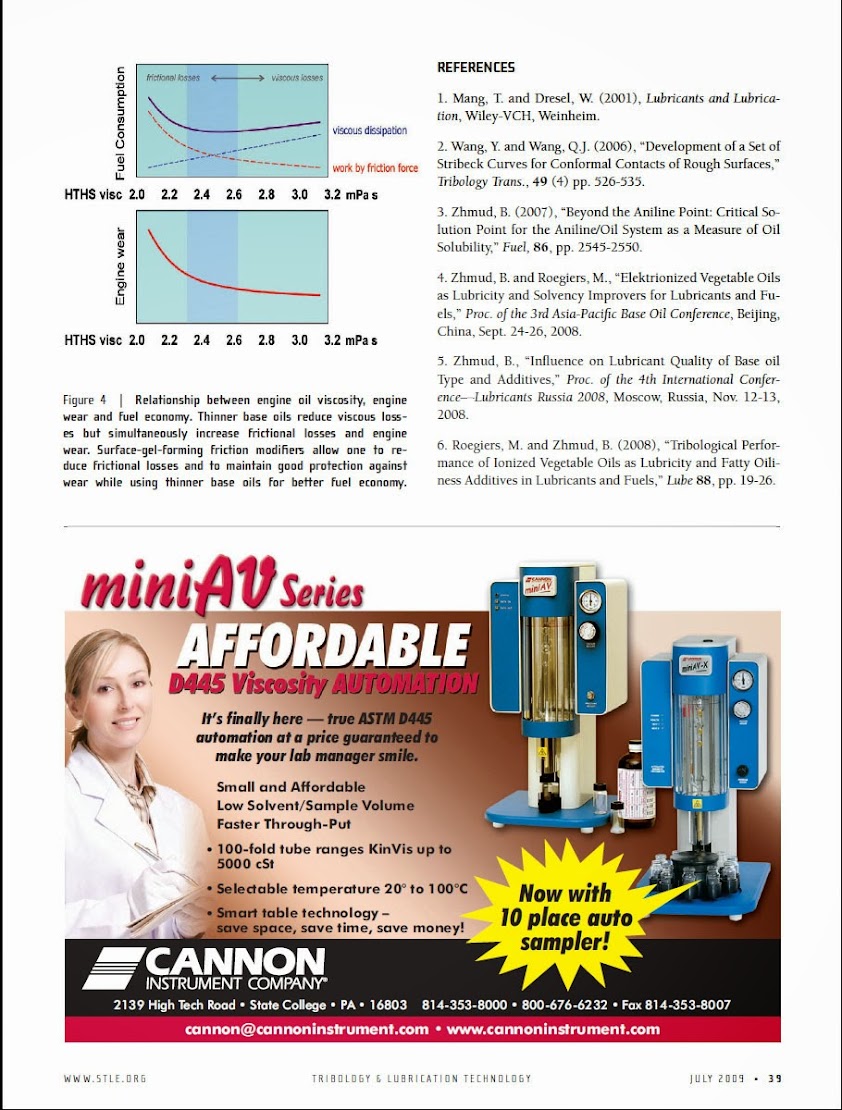

PDF link) on challenges of using more refined base oils, such as Group II, III, IV, and GTL, as well as esters.

Challenges are great, as Group III, IV, and GTL base oils are regarded as "dry oils" with poor solubility and lubricity. Esters have excellent lubricity but they passivate the metal surfaces and block the AW/EP/FM additives and may therefore increase the wear greatly.

The article doesn't seem to discuss the pressure - viscosity coefficient, which is also important for wear protection but the synthetic base oils have poor pressure - viscosity coefficents as well. Despite this apparent omission, the article is excellent and discusses some great disadvantages and challenges of synthetic base oils and how to possibly overcome these challenges and disadvantages.

Just been by theit production site, and all that was left standing was the classified front. the rest was being torn down. Elektrion is no more.