I recently picked up a 2007 Mazda MazdaSpeed 6 that had an engine knock/noise. Here is a video that I took of the engine on a cold start. Hammers for a short time then goes nearly silent followed by some light tick noises.

Video of cold engine start

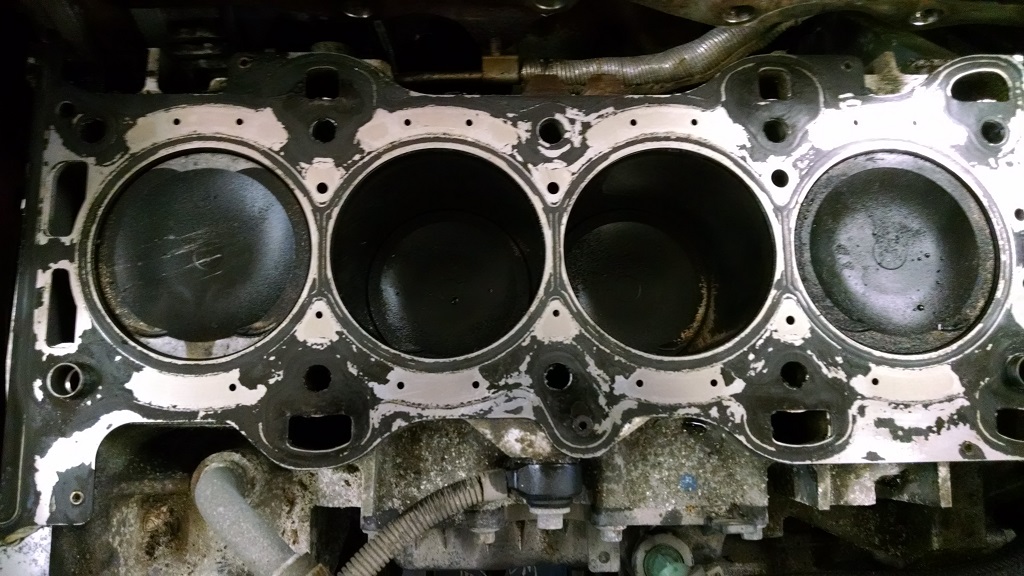

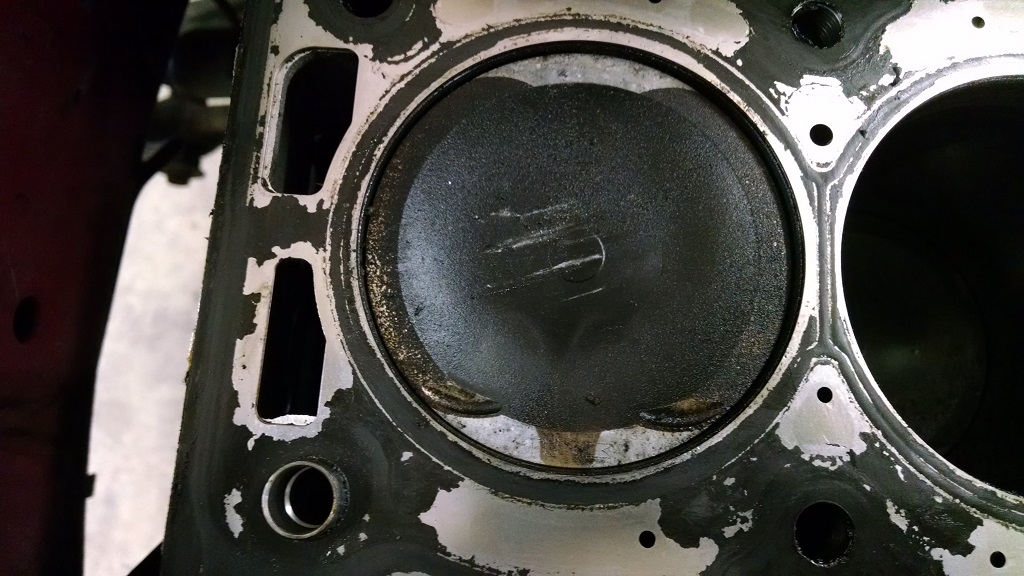

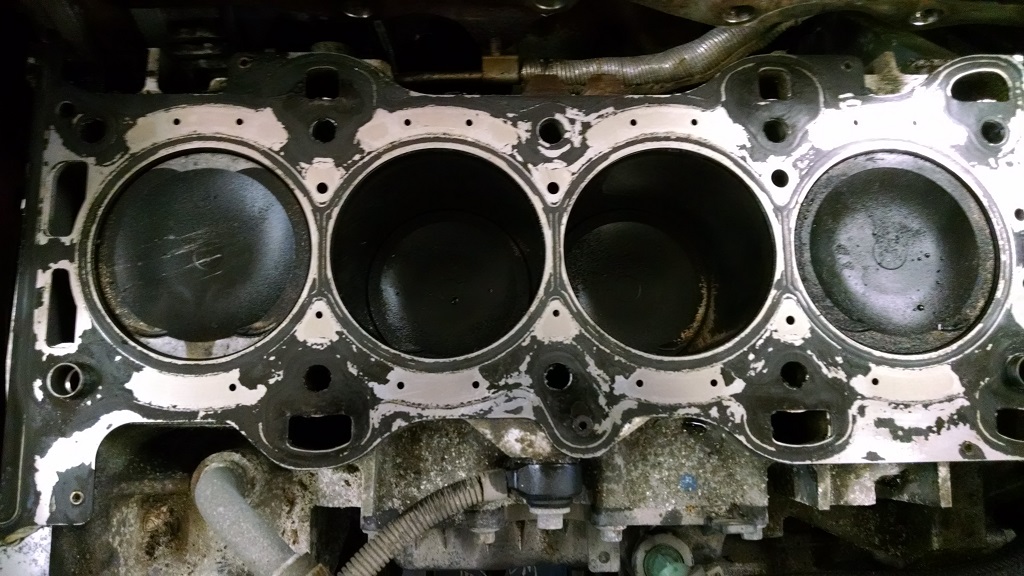

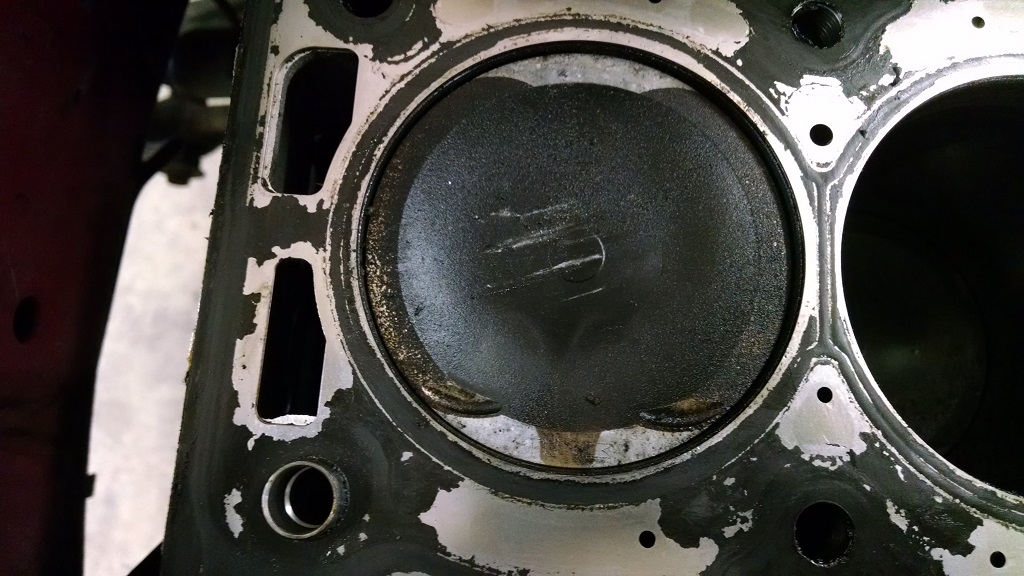

I pulled the cylinder head off and found that the right most piston has indication of getting intimate with the cylinder head. Just enough to clear the carbon from the surface.

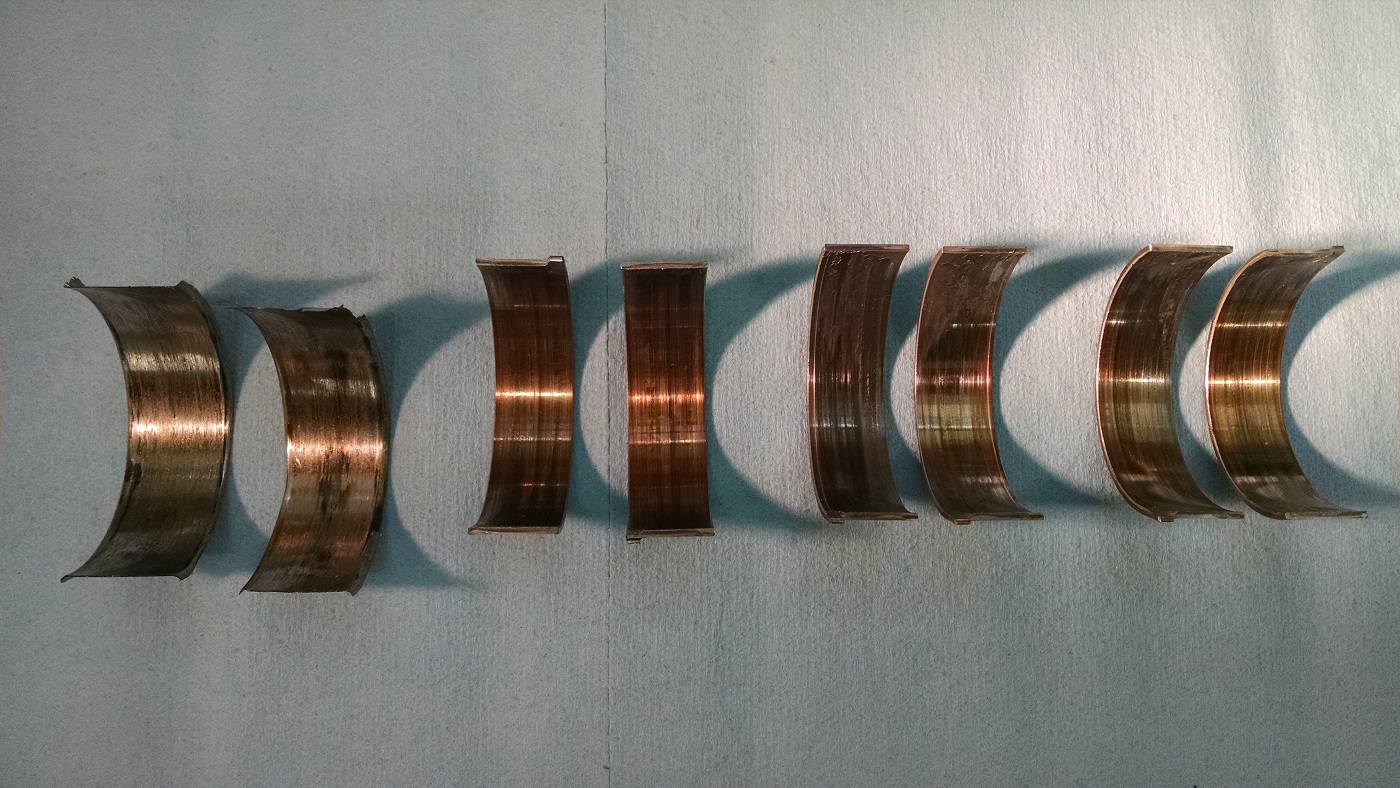

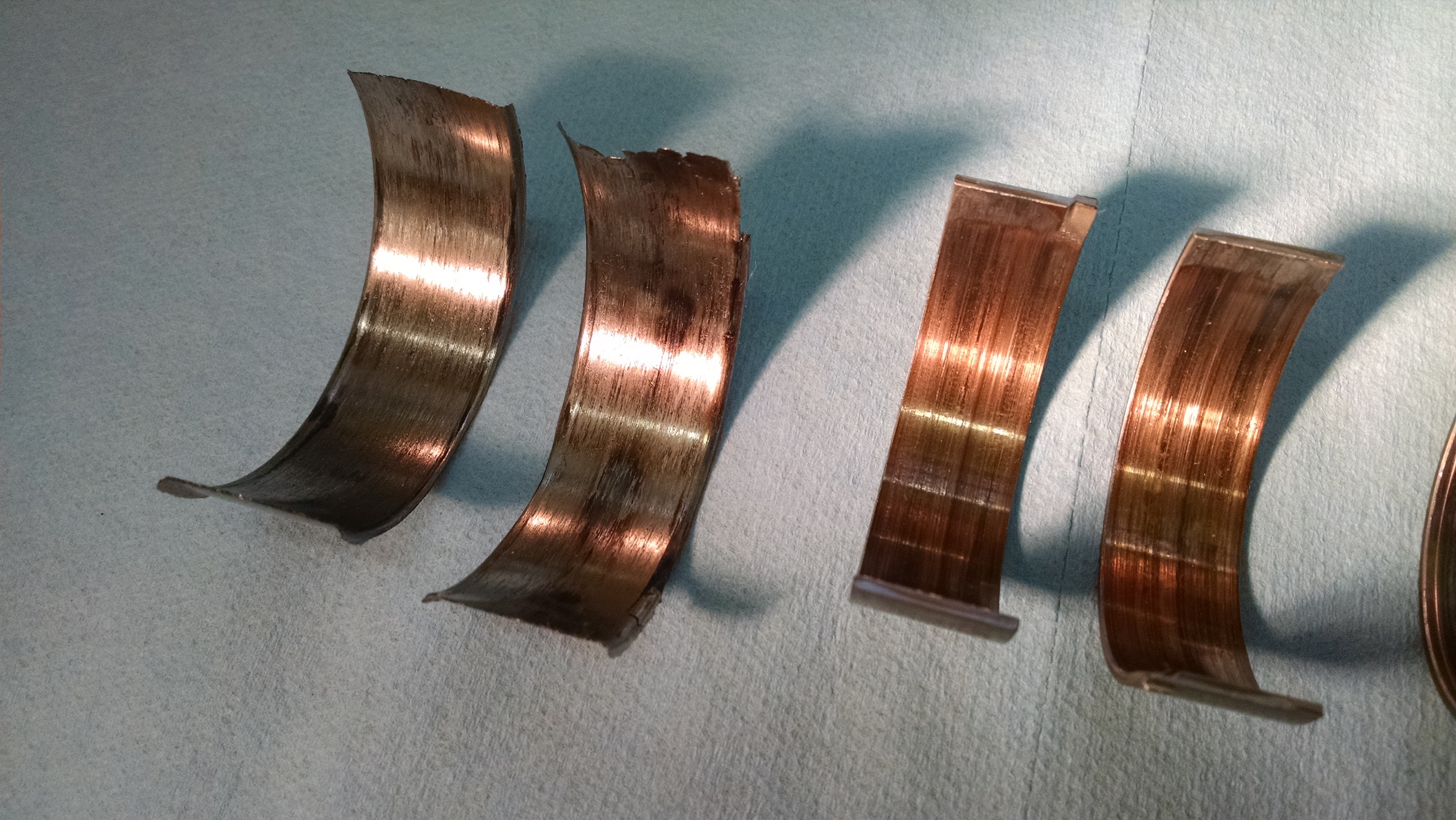

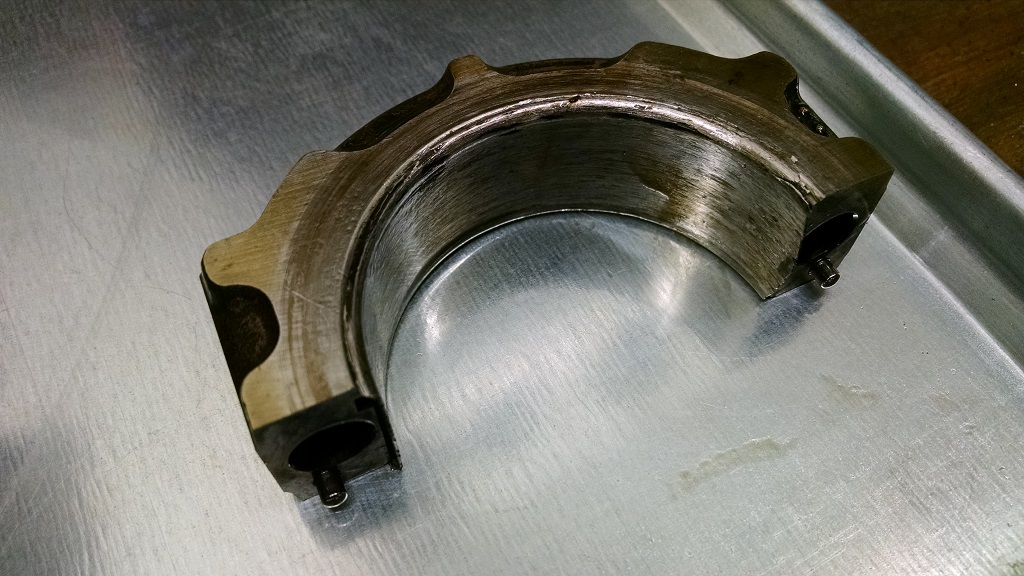

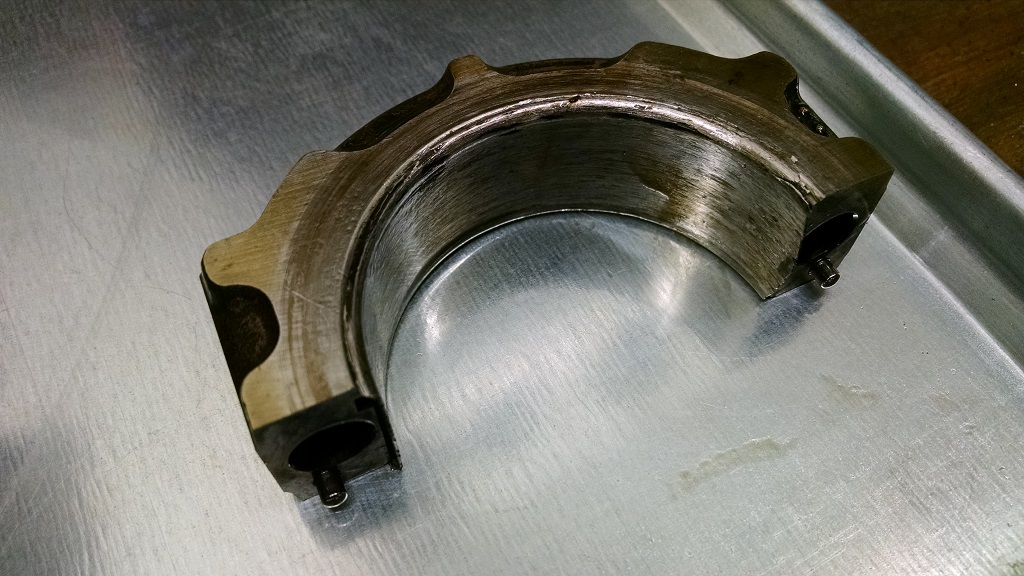

So I then dropped the oil pan and pulled the piston from that cylinder to find a spun rod bearing.

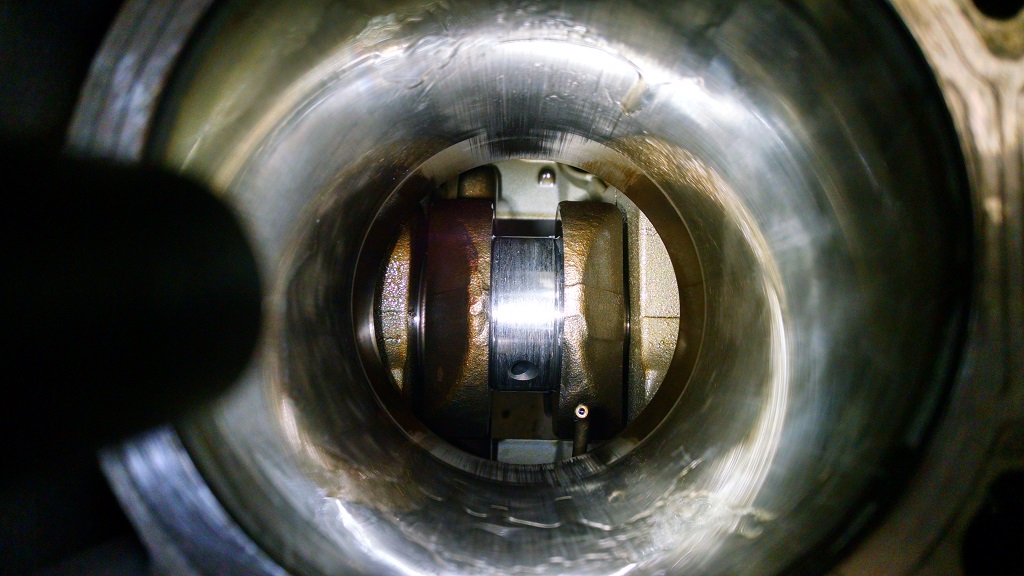

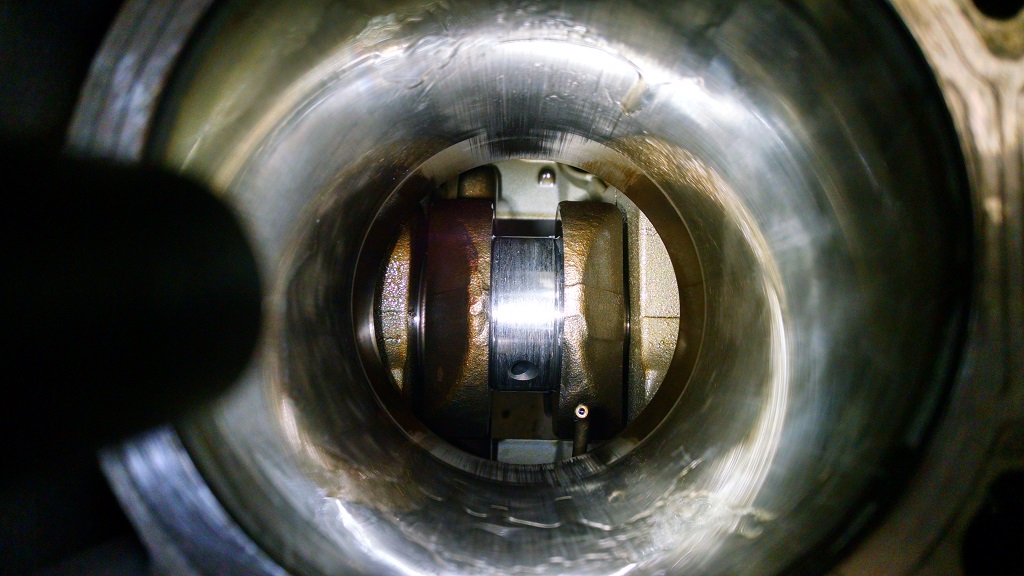

I'm hoping to get some advice from people with a lot more knowledge than me. Could I possibly re-bearing onto this journal from what you can see? I'll mic it tonight and compare measurements to the factory service manual specs.

Video of cold engine start

I pulled the cylinder head off and found that the right most piston has indication of getting intimate with the cylinder head. Just enough to clear the carbon from the surface.

So I then dropped the oil pan and pulled the piston from that cylinder to find a spun rod bearing.

I'm hoping to get some advice from people with a lot more knowledge than me. Could I possibly re-bearing onto this journal from what you can see? I'll mic it tonight and compare measurements to the factory service manual specs.

Last edited: