This may have been discussed but maybe I missed it in a search. There was a short discussion of this grease in the past but it didn't address this topic specifically.

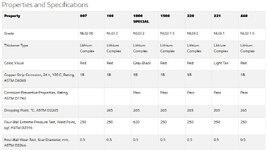

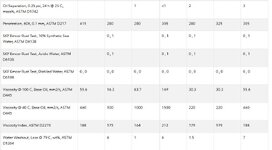

Either way I've been looking specifically at Mobilith SHC 220 grease which uses synthetic PAO oil in a lithium base. It appears to be a very close cousin to Mobil 1 Synthetic grease. They both are NLGI #2 grade regarding overall thickness/viscosity.

The main difference I can find is the viscosity of the base oil is a bit higher (220 vs ~175) in the SHC 220. The four ball weld test however is higher with the Mobil 1, 315kgf versus 250kgf with the Mobilith SHC 220.

This seems contradictory as the Mobilith SHC 220 grease is recommended for heavy duty large off-road mine vehicles, so IDK how important the four ball weld test is regarding wheel bearings.

If you do a search online or youtube you'll find the SHC 220 grease is used mostly for Industrial applications like large bearings in very heavy duty equipment, but also in wheel bearings for large Open Pit Mine trucks, delivery vans, and even race cars.

The issue however is the Mobil has not sent the SHC 220 grease in for GC-LB approval/certification but looking at the specs I would assume it would pass.

I know there're dozens and dozens of good greases to choose from, that's not the question, I'm not looking for suggestions which other grease is "better" or "best", we all have our own preferences, just like

which beer is "best". HA!

And also knowing that a grease manufacturer can chose whether (or not) to send in their grease to be approved by the NLGI and pay the ~$2000 annual fee for the GC-LB certification.

So the question is, if a grease is not certified by NLGI for GC (wheel bearings) does that mean it can't or shouldn't be used in wheel bearings ??

I'm really not looking for opinions from armchair grease experts (aren't we all ), just trying to find someone who's actually used a grease that does not have the NLGI GC-LB stamp of approval and how that worked out for you. Or, if there're any actual lubrication engineers (Tribologists) by trade reading this, please jump in.

), just trying to find someone who's actually used a grease that does not have the NLGI GC-LB stamp of approval and how that worked out for you. Or, if there're any actual lubrication engineers (Tribologists) by trade reading this, please jump in.

Thanks

Either way I've been looking specifically at Mobilith SHC 220 grease which uses synthetic PAO oil in a lithium base. It appears to be a very close cousin to Mobil 1 Synthetic grease. They both are NLGI #2 grade regarding overall thickness/viscosity.

The main difference I can find is the viscosity of the base oil is a bit higher (220 vs ~175) in the SHC 220. The four ball weld test however is higher with the Mobil 1, 315kgf versus 250kgf with the Mobilith SHC 220.

This seems contradictory as the Mobilith SHC 220 grease is recommended for heavy duty large off-road mine vehicles, so IDK how important the four ball weld test is regarding wheel bearings.

If you do a search online or youtube you'll find the SHC 220 grease is used mostly for Industrial applications like large bearings in very heavy duty equipment, but also in wheel bearings for large Open Pit Mine trucks, delivery vans, and even race cars.

The issue however is the Mobil has not sent the SHC 220 grease in for GC-LB approval/certification but looking at the specs I would assume it would pass.

I know there're dozens and dozens of good greases to choose from, that's not the question, I'm not looking for suggestions which other grease is "better" or "best", we all have our own preferences, just like

which beer is "best". HA!

And also knowing that a grease manufacturer can chose whether (or not) to send in their grease to be approved by the NLGI and pay the ~$2000 annual fee for the GC-LB certification.

So the question is, if a grease is not certified by NLGI for GC (wheel bearings) does that mean it can't or shouldn't be used in wheel bearings ??

I'm really not looking for opinions from armchair grease experts (aren't we all

Thanks