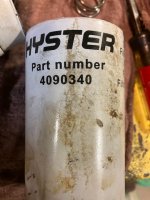

This is off a Mitsubishi/PSI 2.4l in a Hyster forklift. They're scheduled for maintenance at 300 hours but usually get to 500+ before they're released to the shop. This would have been filled with MFA 15w40. Same oil and filter went back in. This one would have been around 500 hours on this OCI.

Easiest can to cut through so far. The ADBV almost feels hard enough to break in your fingers when you bend it. It will flex but is super hard.

This is the diameter of a 51394 but 5.5" tall. I believe they're made by Baldwin but can't prove it. They come in packaged the same exact way as the bulk Baldwin's did when I sold them with the same unique smell. There is no alternative cross reference number for these that we have found at this point.

Easiest can to cut through so far. The ADBV almost feels hard enough to break in your fingers when you bend it. It will flex but is super hard.

This is the diameter of a 51394 but 5.5" tall. I believe they're made by Baldwin but can't prove it. They come in packaged the same exact way as the bulk Baldwin's did when I sold them with the same unique smell. There is no alternative cross reference number for these that we have found at this point.