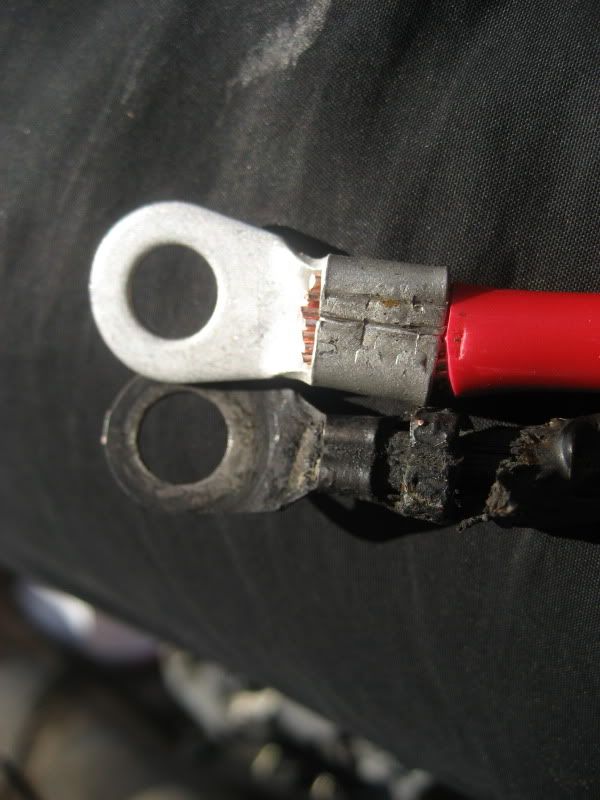

Those red caps were removable - they were capped because there was either noalox stuff in there or dielectric grease. I heavily greased the wire too.

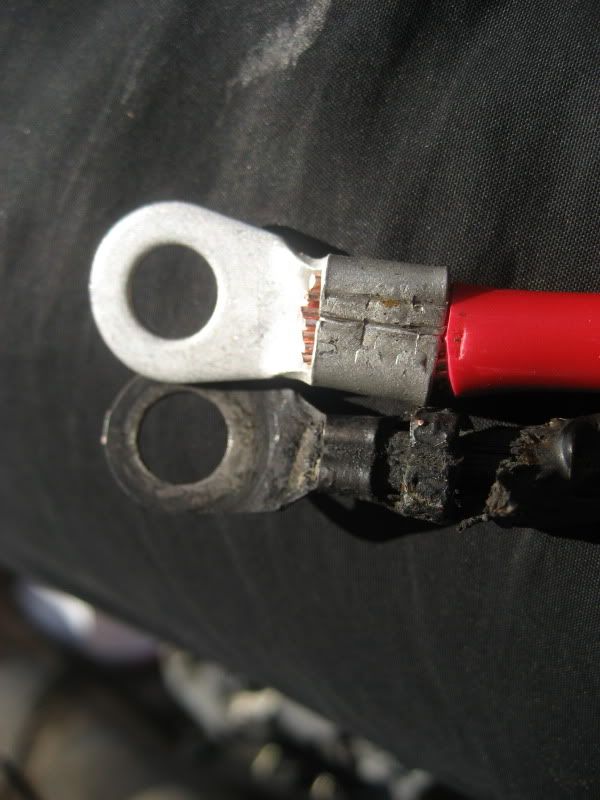

Then did the shrink, then covered it with 130C rated high temperature, thermally conductive 3M electric tape, and from 3M recommendations, covered that with Super 88 tape for the top.

The whole wire goes into a rubber tube that serves as a gasket to a little sealed box that holds some of the terminal end of the ECU harness. So it is effectively sealed at one side and the other side is capped because the terminals on the alternator are in a little box.

I was afraid to try to solder, as in my experience, getting a big wire hot enough means that a huge amount of the wire and insulation gets really hot. So crimping was best. I didnt have a big crimper, so I used mine. I figured that if I see issues, I can always re-crimp or do something else. I left plenty of the original wire there.

What I finally did was this:

Then did the shrink, then covered it with 130C rated high temperature, thermally conductive 3M electric tape, and from 3M recommendations, covered that with Super 88 tape for the top.

The whole wire goes into a rubber tube that serves as a gasket to a little sealed box that holds some of the terminal end of the ECU harness. So it is effectively sealed at one side and the other side is capped because the terminals on the alternator are in a little box.

I was afraid to try to solder, as in my experience, getting a big wire hot enough means that a huge amount of the wire and insulation gets really hot. So crimping was best. I didnt have a big crimper, so I used mine. I figured that if I see issues, I can always re-crimp or do something else. I left plenty of the original wire there.

What I finally did was this: