I've been looking at a compact track loader, the Takeuchi TL12V, that specifies 10w-30 diesel engine oil for the hydraulic fluid. I'd want to use it at temps as low as a little below -30 F. That seems a bit too cold for 10w-30 in my mind, and I was considering an ATF, like Citgo Transgard Multi-Purpose ATF or something similar, as a substitute. It's available at reasonable prices for fluid today, has a low pour point, and a decent VI. I plan on using the same fluid year round, so it would see outdoor air temps in the mid 90s as well. Does that sound like a good idea to anyone else or do you think this is a bad idea? Is there a better substitute I should consider?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ATF for Compact Track Loader Hydraulics?

- Thread starter FarmerGuy

- Start date

ATF works great with cold temps, but I have heard of premature pump and motor failure on when used on some equipment.

For your temps I would look at Mobil DTE 10 Excel Series 46 which is a multi-viscosity oil. Another option is Shell Tellus S3 V46.

For your temps I would look at Mobil DTE 10 Excel Series 46 which is a multi-viscosity oil. Another option is Shell Tellus S3 V46.

ATF works great with cold temps, but I have heard of premature pump and motor failure on when used on some equipment.

For your temps I would look at Mobil DTE 10 Excel Series 46 which is a multi-viscosity oil. Another option is Shell Tellus S3 V46.

Those look like good options. Thanks for pointing them out to me. Do you know any more details about the pump and motor failures with the ATF? Were they really early or did they see some tell tale signs from the failures that indicated what went wrong?

They were not really early, but more in the 1000 to 1500 hour range. Signs were metal in filters and loss of performance/pressure. You don’t really want to cheap out on hydraulic oil, since a single component failure can send metal through entire system and 30-50 hours of system cleaning and flushing may or may not get all the metal out of the system.

They were not really early, but more in the 1000 to 1500 hour range. Signs were metal in filters and loss of performance/pressure. You don’t really want to cheap out on hydraulic oil, since a single component failure can send metal through entire system and 30-50 hours of system cleaning and flushing may or may not get all the metal out of the system.

1000-1500 hrs with metal component failure is pretty concerning. I wonder why that would occur. I thought ATF was essentially hydraulic fluid with a few friction additives for the transmission clutches. I would have figured that a torque converter would be just as rough on the fluid as a hydrostat system, but maybe I missing something.

I’m not exactly talking “compact tractor,” but this is the thread I found with discussion of ATF in loader hydraulics. My 60+ year old Massey Ferguson 204 specifies “Type A“ ATF in its hydraulics and its “ReversOmatic” torque converter. Closet thing today is Dexron III so that’s what I put in the torque converter. I have not yet changed hydraulic oil, but that is coming.

I’m a bit of a packrat (just found a new axle seal for a ‘69 Chev pickup I sold in 1978) and I have some Type-F, Type-FA, and some Dexron/Mercon on my shelf. If the application is hydraulic fluid, not an auto trans, is there any reason not to throw all of my ATF into the hydraulic system?

I’m a bit of a packrat (just found a new axle seal for a ‘69 Chev pickup I sold in 1978) and I have some Type-F, Type-FA, and some Dexron/Mercon on my shelf. If the application is hydraulic fluid, not an auto trans, is there any reason not to throw all of my ATF into the hydraulic system?

MolaKule

Staff member

You said, ",,,Takeuchi TL12V, that specifies 10w-30 diesel engine oil for the hydraulic fluid. I'd want to use it at temps as low as a little below -30 F. That seems a bit too cold for 10w-30 in my mind,..." Not really.I’m not exactly talking “compact tractor,” but this is the thread I found with discussion of ATF in loader hydraulics. My 60+ year old Massey Ferguson 204 specifies “Type A“ ATF in its hydraulics and its “ReversOmatic” torque converter. Closet thing today is Dexron III so that’s what I put in the torque converter. I have not yet changed hydraulic oil, but that is coming.

I’m a bit of a packrat (just found a new axle seal for a ‘69 Chev pickup I sold in 1978) and I have some Type-F, Type-FA, and some Dexron/Mercon on my shelf. If the application is hydraulic fluid, not an auto trans, is there any reason not to throw all of my ATF into the hydraulic system?

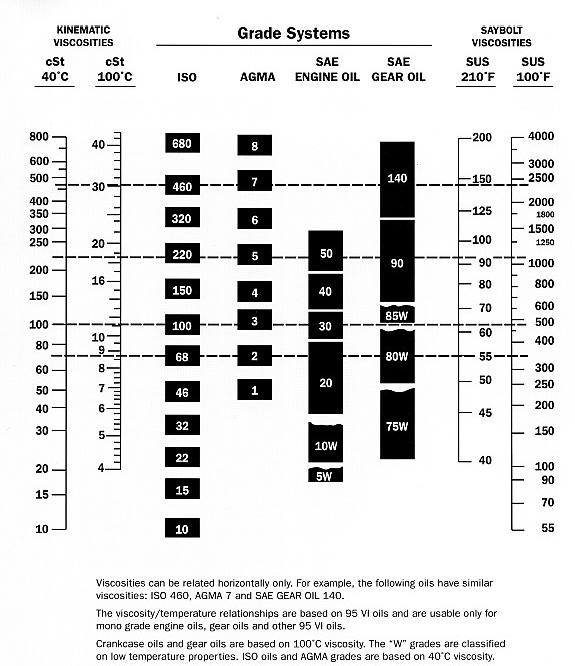

Viscosity Charts - Bob is the Oil Guy

Viscosities can be related horizontally only Viscosities based on 96 VI single grade oils. ISO are specified at 40°C AGMA are specified at 40°C SAE 75w, 80w, 85, 5w, & 10w specified at low temperature. Equivalent viscosities for 100° & 210°F are shown SAE 90 to 250 and 20 to 50 specified at...

bobistheoilguy.com

A 10W30 grade oil falls into the 10.0 cSt viscosity region at 100C, whereas most of the old ATF fluids were around 7.5 to 8 cSt .

Why not use a modern hydraulic oil such as https://www.schaefferoil.com/documents/134-264-td.pdf or similar

in ISO 68 with a 10.5 cSt 100C viscosity and a very low -65F pour point .

Last edited:

Your easiest bet to get there is a 0w40 engine oil. Rotella T6 or P66 Guardol Xt 0w40 - both are in the -50f or more range.

Citgo wise, since you mentioned a citgo product. Their HyDurance AW all temp has a cold pour point of -44f in an AW 46. Which gets you close to that range, as it’s a full synthetic.

You could also look towards Summit Hypar - -49f.

Lubriplate also has a similar product line with their SFGO series:

You could also look into the P66 Synthetic Arctic TO4 fluid. Which is a 0w20, that will go down to -63f range. Being a 0w20 it at least gets you to that ISO 46-68 hybrid range. At 7.9cst it falls a bit below a 30w at 100c. But since that would be hard to reach at -30f, it would be fine.

Citgo wise, since you mentioned a citgo product. Their HyDurance AW all temp has a cold pour point of -44f in an AW 46. Which gets you close to that range, as it’s a full synthetic.

You could also look towards Summit Hypar - -49f.

Lubriplate also has a similar product line with their SFGO series:

You could also look into the P66 Synthetic Arctic TO4 fluid. Which is a 0w20, that will go down to -63f range. Being a 0w20 it at least gets you to that ISO 46-68 hybrid range. At 7.9cst it falls a bit below a 30w at 100c. But since that would be hard to reach at -30f, it would be fine.

I suspect several fluids may be compatible with that application. I’m sure they are better than what was available in 1959.

One concern is compatibility with what I have, including some rather ancient seals. I recently read that, while I used Dexron III in the torque converter in place of the old Type A, Dexron is NOT recommended in the power steering because it harms those seals (which are already bad on my tractor).

Assuming I’m draining my hydraulics and replacing a return line, then refilling, I don’t want to negatively affect any seals.

One concern is compatibility with what I have, including some rather ancient seals. I recently read that, while I used Dexron III in the torque converter in place of the old Type A, Dexron is NOT recommended in the power steering because it harms those seals (which are already bad on my tractor).

Assuming I’m draining my hydraulics and replacing a return line, then refilling, I don’t want to negatively affect any seals.

Similar threads

- Replies

- 1

- Views

- 2K

- Replies

- 6

- Views

- 876

- Replies

- 5

- Views

- 449

- Replies

- 17

- Views

- 476

- Replies

- 2

- Views

- 1K