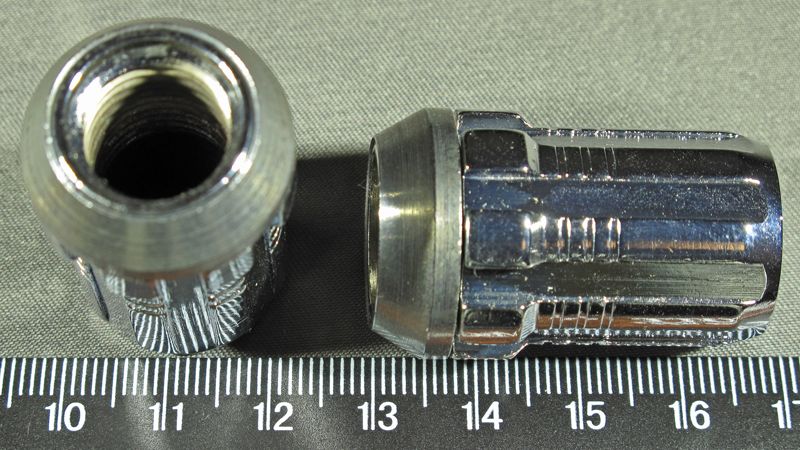

The other day I installed a set of Potenza RE-11A tires on an older, low mileage, 944 Turbo. It had OEM wheels with black, aluminum alloy lug nuts. The owner said they are the original OEM lug nuts that came on the car. I've never seen a car with OEM aluminum lug nuts, which got me thinking....

I've seen alluminun "tuner" nuts for a long time but never really thought about them. The Porsche nuts were super light and seemed pretty cool, which brings me to my question.

Are aftermarket aluminum lug nuts safe for daily driver road use? First thoughts are that aluminum is soft, has different expansion rates, and could have corrosion or seizing issues. That being said, if you have a summer driver which doesn't see all the different elements, would it be OK to use a set?

I'd be a little concerned about them keeping their torque requirements when compared to a steel but, but then again I've never used them. Also, if Porsche was using them way back in 1986, wouldn't there have been an issue by now?

I think it would be pretty cool to have a set on my car with the Enkie wheels I have, but I don't want to die either lol the set of 20 nuts had to have been at least 2 lbs lighter than the steel nuts, if not more.

Anyone have any real world experience with aluminum lug nuts that they could share?

I've seen alluminun "tuner" nuts for a long time but never really thought about them. The Porsche nuts were super light and seemed pretty cool, which brings me to my question.

Are aftermarket aluminum lug nuts safe for daily driver road use? First thoughts are that aluminum is soft, has different expansion rates, and could have corrosion or seizing issues. That being said, if you have a summer driver which doesn't see all the different elements, would it be OK to use a set?

I'd be a little concerned about them keeping their torque requirements when compared to a steel but, but then again I've never used them. Also, if Porsche was using them way back in 1986, wouldn't there have been an issue by now?

I think it would be pretty cool to have a set on my car with the Enkie wheels I have, but I don't want to die either lol the set of 20 nuts had to have been at least 2 lbs lighter than the steel nuts, if not more.

Anyone have any real world experience with aluminum lug nuts that they could share?