As part of the normal process would you replace the rear seal in the engine, since you had the transmission out anyway?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6L80E Build

- Thread starter clinebarger

- Start date

I was wondering about the cost of these two options, (Labor only)

1. Pull 6LX out of truck. Replace torque converter. Put tranny back into truck.

2. Pull 6LX out of truck. Remove torque converter. Open up tranny and re-fresh all clutch material hopefully without a need to replace hard parts. Put in new torque converter. Put tranny back into truck.

The question is for the situation where you have 200,000 miles on the truck and you want to get to 300,000 miles without damaging the transmission. At 300,000 miles either sell the truck or go for the gusto and do a full rebuild.

I find one thing a bit disconcerting is that once that transmission is opened up you are at the total mercy of the tranny shop. I would trust Cline but maybe not some of the other shops out there. Thanks.

1. Pull 6LX out of truck. Replace torque converter. Put tranny back into truck.

2. Pull 6LX out of truck. Remove torque converter. Open up tranny and re-fresh all clutch material hopefully without a need to replace hard parts. Put in new torque converter. Put tranny back into truck.

The question is for the situation where you have 200,000 miles on the truck and you want to get to 300,000 miles without damaging the transmission. At 300,000 miles either sell the truck or go for the gusto and do a full rebuild.

I find one thing a bit disconcerting is that once that transmission is opened up you are at the total mercy of the tranny shop. I would trust Cline but maybe not some of the other shops out there. Thanks.

clinebarger

Thread starter

As part of the normal process would you replace the rear seal in the engine, since you had the transmission out anyway?

Yes.....And reseal the Rear Cover on all LSx engines as it's more prone to leak than the Rear Main Seal.

clinebarger

Thread starter

I was wondering about the cost of these two options, (Labor only)

1. Pull 6LX out of truck. Replace torque converter. Put tranny back into truck.

2. Pull 6LX out of truck. Remove torque converter. Open up tranny and re-fresh all clutch material hopefully without a need to replace hard parts. Put in new torque converter. Put tranny back into truck.

The question is for the situation where you have 200,000 miles on the truck and you want to get to 300,000 miles without damaging the transmission. At 300,000 miles either sell the truck or go for the gusto and do a full rebuild.

I find one thing a bit disconcerting is that once that transmission is opened up you are at the total mercy of the tranny shop. I would trust Cline but maybe not some of the other shops out there. Thanks.

2008 4x4 Suburban 2500

Number 1.....

*R&R Torque Converter calls for 6.8 hours At my $100 per hour......$680

*Reseal Rear Cover, 1 hour....$100

Number 2 is complicated, But to JUST refresh the frictions, reseal & install new "Torlon" checkballs in the valve Body is a flat $400 labor.

What's complicated is the warranty aspect.

Well considering the 6L90E behind the LSA in my car has just ticked over 8700kms, (5400 miles), I'm hoping I'll be good to go for a while yet..However.....I still see 6L90E failures in the 225-250,000 mile range

Out of curiousity, how many days would a full rebuild of a 6L80 take for you if you had the parts in-hand prior to the vehicle showing up?

Thanks for mentioning that. I've noticed three different methods of sealing the plate. Some mechanics, (actually I'm not sure they were pro's) place the plate gasket on with no sealant and put the plate on and bolted up, one dabbed sealant at the two corners at the bottom of the plate, and one carefully placed a bead along where the bottom of the plate would sit. As a separate issue I watched a U tube video where they used a centering device to center the place and to push the seal on afterwards.Yes.....And reseal the Rear Cover on all LSx engines as it's more prone to leak than the Rear Main Seal.

I posted this video to show how the centering device works for the Bittog readers. You mentioned sealing. Is there something you can tell us about that topic? Thanks very much. Snag.

Last edited:

It's a GM trans lol.

Shoulda added a /s for "sarcastic." clinebarger is maybe the most awesome trans guy on BITOG and his wealth of knowledge is amazing.

clinebarger

Thread starter

Thanks for mentioning that. I've noticed three different methods of sealing the plate. Some mechanics, (actually I'm not sure they were pro's) place the plate gasket on with no sealant and put the plate on and bolted up, one dabbed sealant at the two corners at the bottom of the plate, and one carefully placed a bead along where the bottom of the plate would sit. As a separate issue I watched a U tube video where they used a centering device to center the place and to push the seal on afterwards.

I posted this video to show how the centering device works for the Bittog readers. You mentioned sealing. Is there something you can tell us about that topic? Thanks very much. Snag.

I RTV the joints & use a similar tool as shown in the video. If you need RTV across the bottom of the rear cover.....You need a new Pan Gasket.

Any 6l80 experts:

I just rebuilt a 6L80 for a guy that drove for weeks with a grenading torque converter. Needless to say it was ugly.

Burned up 1234 and 456 plus cracked 1234 piston. Also broke the 456 hub dampener and tore up both sides of the pump. Surprisingly the only valve that was stuck in the valve body was the compensator feed. After correcting all of the above and getting the truck on the road I have a few issues.

I am aware of the relearn requirement but figured just driving would allow the computer to sort out the new parameters.

The issues are:

1) a pause then grab feeling 1-2 shift

2) a hard 2-1 down shift

3) a very hard 4-5 shift(the worst and most obvious problem)

The 2-3 is pretty smooth but sometimes has a little firm bump.

3-4 is good and 5-6 is good.

I am not sure how long it takes the computer to learn new shift strategies but even so the 4-5 shift is bad enough that I don't believe it is program related.

Thanks in advance to anyone that replies.

Almost forgot.

I installed a Superior valve body kit and Superior pump upgrade kit.

I just rebuilt a 6L80 for a guy that drove for weeks with a grenading torque converter. Needless to say it was ugly.

Burned up 1234 and 456 plus cracked 1234 piston. Also broke the 456 hub dampener and tore up both sides of the pump. Surprisingly the only valve that was stuck in the valve body was the compensator feed. After correcting all of the above and getting the truck on the road I have a few issues.

I am aware of the relearn requirement but figured just driving would allow the computer to sort out the new parameters.

The issues are:

1) a pause then grab feeling 1-2 shift

2) a hard 2-1 down shift

3) a very hard 4-5 shift(the worst and most obvious problem)

The 2-3 is pretty smooth but sometimes has a little firm bump.

3-4 is good and 5-6 is good.

I am not sure how long it takes the computer to learn new shift strategies but even so the 4-5 shift is bad enough that I don't believe it is program related.

Thanks in advance to anyone that replies.

Almost forgot.

I installed a Superior valve body kit and Superior pump upgrade kit.

clinebarger

Thread starter

Do a reset & relearn, If that doesn't help.....Pull the pan & see if any left over contamination is present.

The 1234/35R Drum is quite the complicated array of O-rings & Lip Seals.....I've seen experienced builders misbuild this drum!!!

The 1234/35R Drum is quite the complicated array of O-rings & Lip Seals.....I've seen experienced builders misbuild this drum!!!

Yes I have ordered a seal sub kit for the 1234 35R drum knowing that I will be going back in. The clue is that 3rd bumps occasionally which is the 35R applying on top of the 1234 and of course the 5th bang is the 35R applying on top of the 456. So the 35R is the common factor there. I dont have the software to do a reset. Do you really think it is necessary? I mean the computer is adaptive right?Do a reset & relearn, If that doesn't help.....Pull the pan & see if any left over contamination is present.

The 1234/35R Drum is quite the complicated array of O-rings & Lip Seals.....I've seen experienced builders misbuild this drum!!!

Also, Is the fluid level that critical? I effed up and overfilled the sh!t out of the thing because the torque converter was full already. Today i am going to suck a couple quarts out and pray to the transmission gods but we both know how that will turn out....I have overfilled transmissions in the past and all that happened was they might have vented or leaked some. Never any shifting issues. And yah that drum is a Beeoch.Do a reset & relearn, If that doesn't help.....Pull the pan & see if any left over contamination is present.

The 1234/35R Drum is quite the complicated array of O-rings & Lip Seals.....I've seen experienced builders misbuild this drum!!!

And while I have you. What is your take on the compensator feed system? Is one of its functions to act as an accumulator? In other words could the hard shifts be analogous to no accumulation in the older designs? I am wondering if I screwed up that **** piston dam seal.Do a reset & relearn, If that doesn't help.....Pull the pan & see if any left over contamination is present.

The 1234/35R Drum is quite the complicated array of O-rings & Lip Seals.....I've seen experienced builders misbuild this drum!!!

I also have a 2002 Avalon V6 with a terrible oil leak I am working on. Any tips on that? It looks high like valve cover but could be cam seal or cover.

- Joined

- Sep 26, 2010

- Messages

- 9,837

The customer's lucky day was having his vehicle towed to @clinebarger's shop. Great write up!

clinebarger

Thread starter

Yes, The TCM is adaptive.....But will not make big changes quickly. I always try to leave it be, But if it's acts stupid....I reset them & run a Quick Learn.Yes I have ordered a seal sub kit for the 1234 35R drum knowing that I will be going back in. The clue is that 3rd bumps occasionally which is the 35R applying on top of the 1234 and of course the 5th bang is the 35R applying on top of the 456. So the 35R is the common factor there. I dont have the software to do a reset. Do you really think it is necessary? I mean the computer is adaptive right?

The Quick Learn allows big changes as the TCM learns the clutch fill volumes.

Never overfilled one....But yes, If it's high enough to Foam/Aerate the fluid....That will cause issues.Also, Is the fluid level that critical? I effed up and overfilled the sh!t out of the thing because the torque converter was full already. Today i am going to suck a couple quarts out and pray to the transmission gods but we both know how that will turn out....I have overfilled transmissions in the past and all that happened was they might have vented or leaked some. Never any shifting issues. And yah that drum is a Beeoch.

Compensator pressure greatly affects shift feel & clutch timing, Without it or in the case of a missing/cut compensator seal....The oncoming clutch cannot be controlled & will result in a harsh shift.And while I have you. What is your take on the compensator feed system? Is one of its functions to act as an accumulator? In other words could the hard shifts be analogous to no accumulation in the older designs? I am wondering if I screwed up that **** piston dam seal.

I also have a 2002 Avalon V6 with a terrible oil leak I am working on. Any tips on that? It looks high like valve cover but could be cam seal or cover.

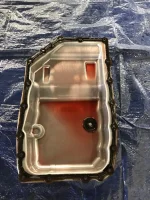

Thanks for the info Mr. Clinebarger. I just finished a pan drop, magnet cleanup and filter replacement. This is on my 2008 6L90 with 215,000 miles. I’m hoping this looks pretty good and plan to open up the filter to have a look. I hope to continue to 250,000 miles. So far it is still shifting smoothly.2008 4x4 Suburban 2500

Number 1.....

*R&R Torque Converter calls for 6.8 hours At my $100 per hour......$680

*Reseal Rear Cover, 1 hour....$100

Number 2 is complicated, But to JUST refresh the frictions, reseal & install new "Torlon" checkballs in the valve Body is a flat $400 labor.

What's complicated is the warranty aspect.

Last edited:

@clinebarger

I am going to be getting another 6L80 with converter failure this week and wonder if I could get the source for one of the Sonnax mod converters and a rough cost. Thanks

I am going to be getting another 6L80 with converter failure this week and wonder if I could get the source for one of the Sonnax mod converters and a rough cost. Thanks

clinebarger

Thread starter

Get ahold of Bill at B&I Torque Converter in Oklahoma City....He's built the last 2 6L80E converters I've needed. Tell him you need a stock stall Billet Front 6L80E Converter.

I was using a local outfit to build them using the Sonnax Kit.....The Sonnax Kit is on backorder right now.

I was using a local outfit to build them using the Sonnax Kit.....The Sonnax Kit is on backorder right now.

Similar threads

- Replies

- 22

- Views

- 7K

- Replies

- 23

- Views

- 16K